Tjernlund DCOP1 Constant Operating Pressure Draft Control 8504174 (Discontinued) User Manual

Page 8

7

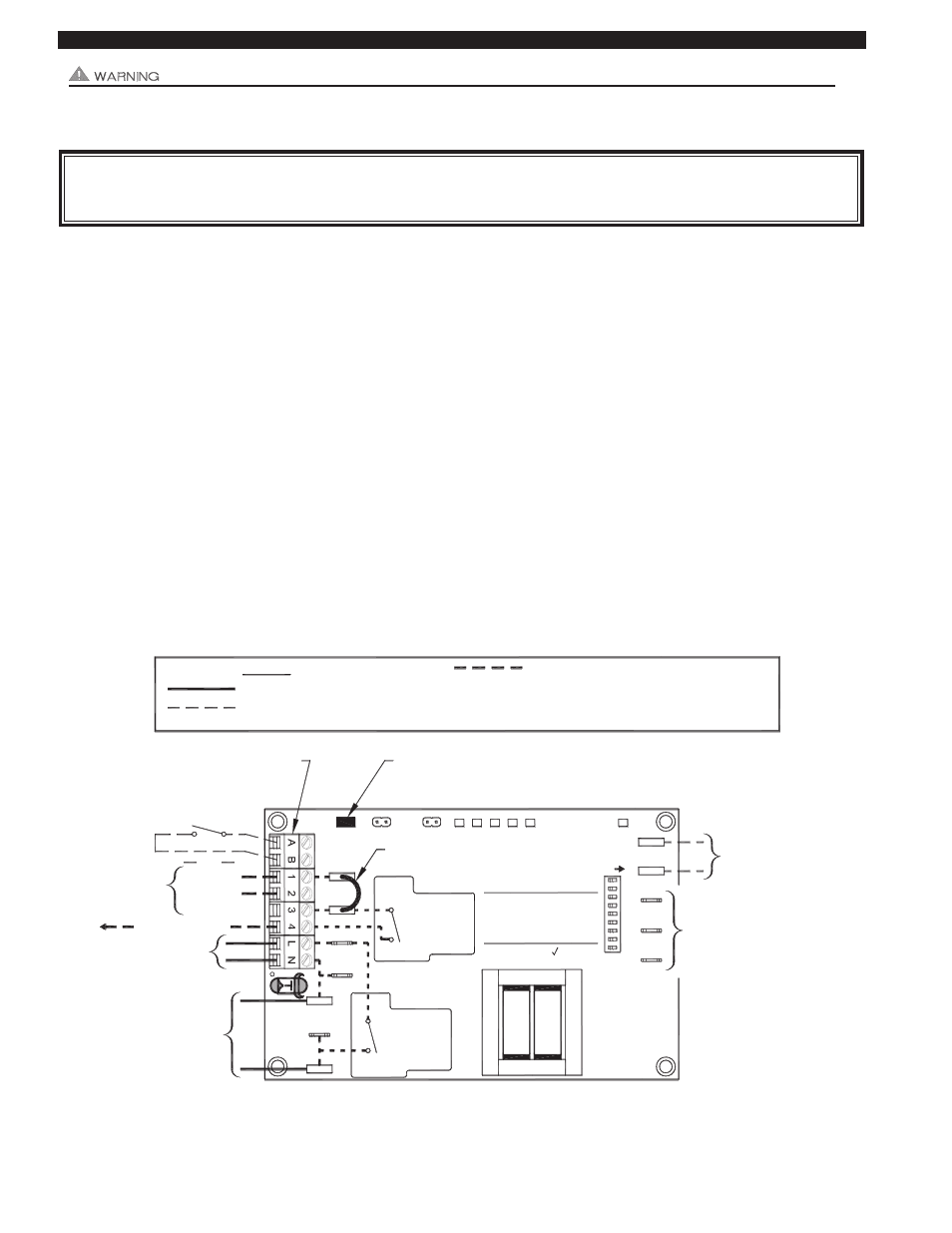

UC1 UNIVERSAL CONTROL WIRING

All wiring from the UC1 to the appliance(s) must be appropriate Class 1 wiring as follows: installed in rigid metal conduit, intermediate

metal conduit, rigid non-metallic conduit, electrical metallic tubing, Type MI Cable, Type MC Cable, or be otherwise suitably protected

from physical damage

SEQUENCE OF OPERATION WITH UC1 UNIVERSAL CONTROL AND 24 VAC OR 115 VAC HEATER CONTROL CIRCUIT:

Control signal from thermostat, aquastat, primary control or gas valve is intercepted and routed to terminal "1" on UC1 terminal

strip. When terminal "1" is energized with either 24 VAC or 115 VAC, the COP controller energizes the Inducer motor. After draft is

established, the PSA-1 Fan Proving Switch closes energizing terminal "4", which completes the circuit allowing burner to fire.

NOTE:The burner will not fire until the 5 second factory set pre-purge time is finished. The Inducer will continue to run after the

burner has finished firing for the 2 minute factory set post-purge time. See "Pre / Post-Purge Settings" on page 3 for details.

The "1" input terminal on the UC1 can accept either a 24 VAC or 115 VAC control signal. IMPORTANT: The RED voltage

jumper must be positioned based on appliance interlock voltage 24V or 115V. If using the “DRY” contact activation method, use

terminals A & B on UC1 control and position the RED voltage jumper tab in the “DRY” position. See millivolt appliance interlock

diagram for further information. IMPORTANT: Only one interlock method (i.e. 24V, 115V or “Dry”) can be used with the UC1.

Multiple appliance interlocks require the use of our MAC-Series multiple appliance controls.

The steps listed under each diagram are intended as a supplement to the diagram. Wiring colors or designations may vary by

manufacturer. If you are unable to wire the UC1 as outlined in these instructions, call Tjernlund’s Customer Service Department

toll free at 1-800-255-4208 for assistance.

IMPORTANT: If the call for heat interlock signal or 115 VAC power is removed, the UC1 board will reset and any fault, if present,

will be stored in memory instead of displayed. See page 3, “Checking Memory for Last Fault Code”.

UC1 UNIVERSAL CONTROL WIRING SCHEMATIC

IMPORTANT: MORE THAN ONE INTERLOCK METHOD MAY BE APPLICABLE

In many cases it is easier to interlock with the thermostat/aquastat portion of the heater control circuit vs. the ignition module /

primary control portion of the heater control circuit. Review all of the wiring diagram options prior to choosing the best method.

K1

INTERLOCK

RELAY

J1

COM

J2

JUMPER

CALL

G

R

EEN

RE

D

RE

D

AMBER

BL

U

E

MAC1E OR MAC4E

DEVICES. DO NOT

CONNECT POWER

WILL DAMAGE THE

OR F. DOING SO

TO P1, P2, C, GND

FOR TJERNLUND

GND

8

9

F

CONTROL.

AUXILIARY

34

2

67

5

C

1

P1

ON

P2

AS APPLIANCE INTERLOCK VOLTAGE.

RED JUMPER POSITION MUST BE THE SAME

DO NOT SUPPLY VOLTAGE

TO "A" OR "B".

IMPORTANT:

LED3

LED5 LED4

LED2 LED1

LED6

NEUTRAL

LINE / HOT

COMMON /

CALL SWITCH

USER-PROVIDED

INTERCEPTED

CALL FOR

APPROVED CALL

OR

HEAT

"DRY"

P2 PROVER ON

TERMINAL STRIP

FACTORY WIRED

TO DCOP1 P1 AND

FACTORY WIRED TO

L AND N ON DCOP1

TO DCOP1 T6 AND T9

FACTORY CONNECTED

POWER TERMINALS

24 OR 115 VAC

APPROVED CALL BACK TO HEATER

INTERCEPTED CALL COMMON OR NEUTRAL

24 OR 115 VAC INTERCEPTED CALL FOR HEAT

5 VDC BOARD-GENERATED POWER

DO NOT SUPPLY POWER!

115 VAC

LEGEND:

TERMINAL 2:

TERMINAL 1:

TERMINAL 4:

FIGURE 8050029 3-28-11

LE

D

PO

W

E

R

RE

D

DRY

24V

115V

(1 - 2)

PRE-PURGE SETTINGS

(3 - 8)

(9)

OPEN PROVER OPTION

POST-PURGE SETTINGS

RELAY

MTR

NO

INC

.

9

183006

TJE

R

NL

U

N

D

PR

OD

U

C

T

S

,

R

XL

K2

MOTOR

COM

M

N

XN

NO

WARNING: Disconnect power supply from the DCOP1 and heating equipment when making wiring connections and servicing the

Inducer. Failure to do so may result in personal injury and/or equipment damage. LED #6 (RED) should be off with

power removed.