Rice Lake BCi Belt Scale - Maintenance & Troubleshooting Manual User Manual

Page 8

4

Belt Scale Maintenance Instructions

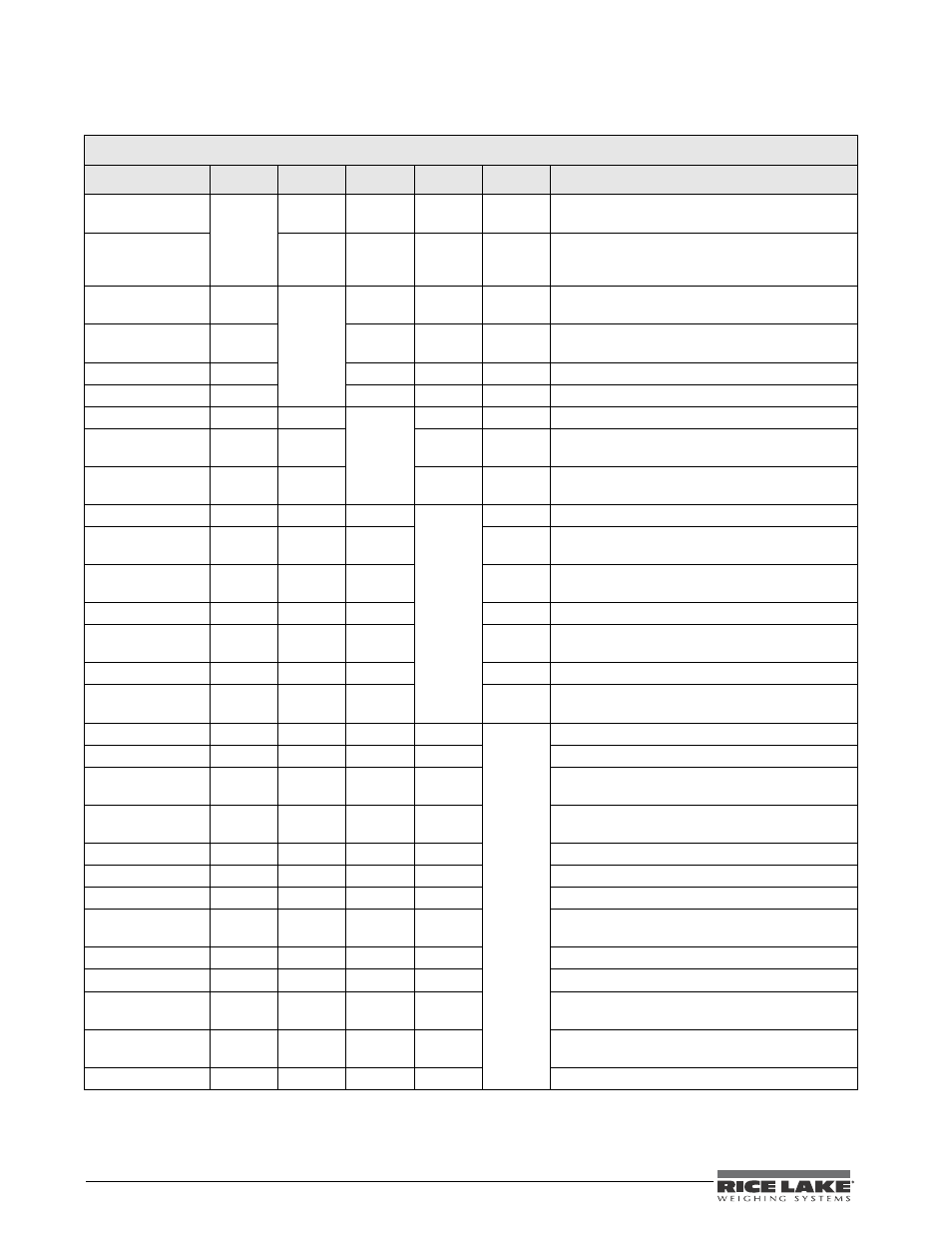

Belt Scale Maintenance Checklist

Item

Daily

Weekly

Monthly

Quarterly

Annually

Description

Scale area - debris

x

Clean scale area. Determine cause of debris and take

steps to remedy

Zero calibration

Perform zero calibration procedure. If change is

greater than .25%, identify cause and correct. Record

results.

Condition of idler

rolls

X

Inspect idlers for wear and damage. Replace rolls and

bearings as necessary.

Span calibration

Perform auto span simulated load tests. Check

repeatabilty and record results.

Belt scraper

Adjust or replace blades if worn.

Belt condition

Visual inspections for cuts, tears, or worn edges

Belt take-up

X

Inspect for free travel, (bearings, belts, etc)

Speed pulley

Inspect for wear, material build-up, belt wrap. Check

bearings also.

Speed sensor

coupling

Inspect for tightness, wobble and corrosion

Load cell offset

X

No load output must be within 1% of rated maximum

Load cell balance

Multiple load cell scales must be balanced to within 1

mV

Static weight

condition

Check for corrosion, location and clearances

Resolution time

Verify time for 1 belt revolution at maximum speed

Zero reference

number

Compare zero number with reference an maximum

change is 2%/year

Audit trail

Review scale history

Line voltage

Measure hot and neutral. Hot to ground, neutral to

ground and correct as needed.

Alignment

X

Complete per manual

Excitation

Verify value and stability

Belt length

Measure and verify. Perform acquire test duration if

changes noted.

Check rods

Inspect check rods. Rods must be straight, spherical

washers without corrosion.

I/O

Check and verify performance of all I/O being used.

Dead band

Confirm settings and adjust if necessary

Auto zero track limit

Record data

Auto zero track

correction

Record data

Passwords

Confirm and revise if required

Wire terminations

Inspect for tightness and corrosion

Cable integrity

Visual and ohm check (corrosion, moisture,

deterioration)

Spherical washers

Inspect for corrosion, pitting, etc. Replace if

necessary

Material factors

Verify with weighed load test.

Table 2-1. Maintenance Checklist