Cable grounding, Power specifications, Parts kit contents – Rice Lake 920i Deep Enclosure User Manual

Page 2

2

920i

Deep Enclosure Installation Instructions

Deep enclosure models of the

920i

provide eight cord

grips for cabling into the indicator. The parts kit

includes cord grip plugs to prevent moisture from

entering the enclosure. Install these plugs into all cord

grips that will be not be used in your application. Use

the cable grounding instructions below for wiring into

the indicator.

Cable Grounding

Cables routed through the cord grips should be

grounded against the indicator enclosure. Do the

following to ground shielded cables:

•

Use the lockwashers, clamps, and kep nuts

provided in the parts kit to install grounding

clamps on the enclosure studs adjacent to cord

grips. Install grounding clamps only for cord grips

that will be used; do not tighten nuts.

•

Route cables through cord grips and grounding

clamps to determine cable lengths required to

reach cable connectors. Mark cables to remove

insulation and shield as described below:

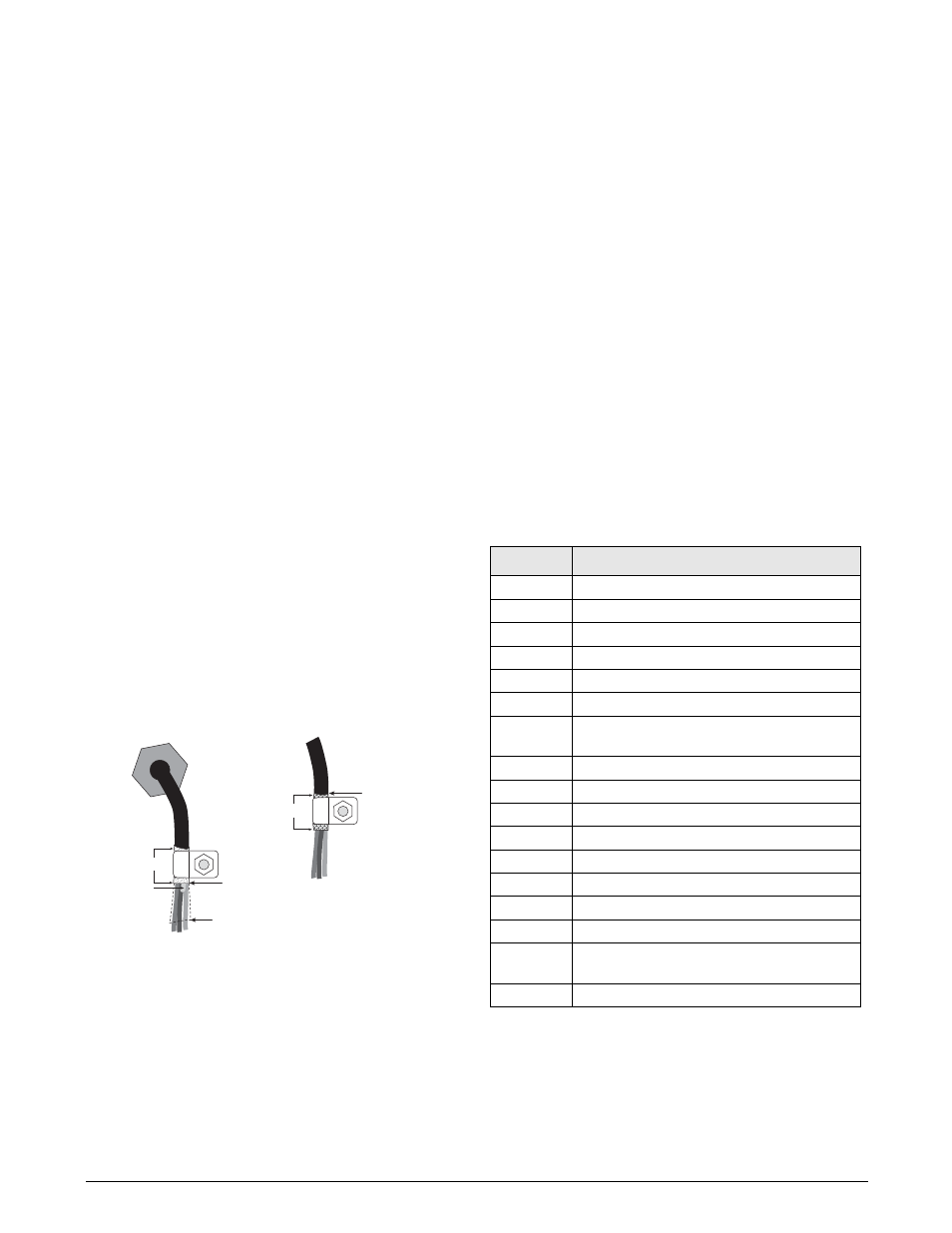

• For cables with foil shielding, strip insulation

and foil from the cable half an inch (15 mm)

past the grounding clamp (see Figure 2). Fold

the foil shield back on the cable where the cable

passes through the clamp. Ensure silver

(conductive) side of foil is turned outward for

contact with the grounding clamp.

• For cables with braided shielding, strip cable

insulation and braided shield from a point just

past the grounding clamp. Strip another half

inch (15 mm) of insulation only to expose the

braid where the cable passes through the clamp.

Figure 2. Grounding Clamp Attachment for Foil-Shielded

and Braided Cabling

•

For load cell cables, cut the shield wire just past

the grounding clamp. Shield wire function is

provided by contact between the cable shield and

the grounding clamp.

•

Route stripped cables through cord grips and

clamps. Ensure shields contact grounding clamps

as shown in Figure 2. Tighten grounding clamp

nuts.

•

Finish installation using cable ties to secure

cables inside of indicator enclosure.

Power Specifications

Line Voltages

115 or 230 VAC

Frequency

50 or 60 Hz

Maximum Power Consumption, 65W on secondary

Primary power consumption: 100W TRMS

Constant current:

1.5 A TRMS (115VAC);

1.0 A TRMS (230VAC)

Fusing

115 VAC and 230 VAC North American

2 x 3.15A TR5 subminiature fuses

Wickmann Time-Lag 19374 Series

UL Listed, CSA Certified and Approved

230 VAC European

2 x 3.15A TR5 subminiature fuses

Wickmann Time-Lag 19372 Series

UL Recognized, Semko and VDE Approved

See the

920i

Installation Manual, PN 67887, for

additional specifications.

Parts Kit Contents

Table 1 lists the parts kit contents for deep enclosure

models of the

920i

.

$PSEHSJQ

*OTVMBUFEDBCMF

'PJM TJMWFSTJEFPVU

(SPVOEJOHDMBNQ

4IJFMEXJSF DVU

-FOHUIPGGPJMCFGPSFGPMEJOH

CBDLPODBCMFJOTVMBUJPO

$VUJOTVMBUJPOIFSF

GPSGPJMTIJFMEFEDBCMFT

#SBJE

$VUJOTVMBUJPOIFSF

GPSCSBJEFEDBCMFT

/05&*OTUBMMMPDLXBTIFST

mSTU BHBJOTUFODMPTVSF

VOEFSHSPVOEJOHDMBNQ

PN

Description

14626

Kep nuts, 8-32NC (4)

14862

Machine screws, 8-32NC x 3/8 (12)

15133

Lock washers, No. 8, Type A (4)

15144

Nylon washers (2)

15631

Cable ties (4–single A/D, 6–dual A/D)

15665

Reducing glands for 1/2 NPT cord grips (2)

15887

6-position screw terminal for load cell

connection (1–single A/D, 2–dual A/D)

19538

Cord grip plugs (4–single A/D, 3–dual A/D)

30623

Fillister head screws, 8-32NC x 7/16 (2)

42149

Rubber feet for tilt stand (4)

42350

Capacity label (1–single A/D, 2–dual A/D)

53075

Cable shield ground clamps (4)

68403

Wing knobs for tilt stand (2)

70599

6-position screw terminals for J2 and J10 (2)

71125

3-position screw terminal for J11 (1)

71126

4-position screw terminal for J9 and optional

keyboard connection (2)

75062

Sealing washers (14)

Table 1. Parts Kit Contents