Origin Live Enterprise C User Manual

Page 5

Page 5

CARRY OUT A VISUAL CHECK on the position of

the yoke as you turn the adjuster screw, to see when it

starts lifting the yoke - never just keep turning the screw

more than 2 turns at this stage once you have seen the

yoke lift off the turret plate.

Th e second way of adjusting to ground datum AND

checking that it is correct is to insert a peice of thin paper

between the underside protrusion and the turret plate.

Adjust the screw anticlockwise very slightly so that when

the paper is inserted between the protrusion and the

turret plate it is held there while you press down on the

turret with your thumb. Keep the pressure on with your

thumb and at the same time very gently pull on the paper

to give it a bit of tension. Now turn the adjuster screw

clockwise to raise the yoke - the point at which the paper

becomes free is the “ground datum position”.

Do the same for the other adjuster screw and use your

“paper feeler gauge” to check that both sides are the same

(i.e both protrusions sit just

just

clear of the turret plate by

just

just

the thickness of a paper sheet).

Once both adjuster screws are at the ground datum

simply wind them both in exactly 3 turns each in a

clockwise direction.

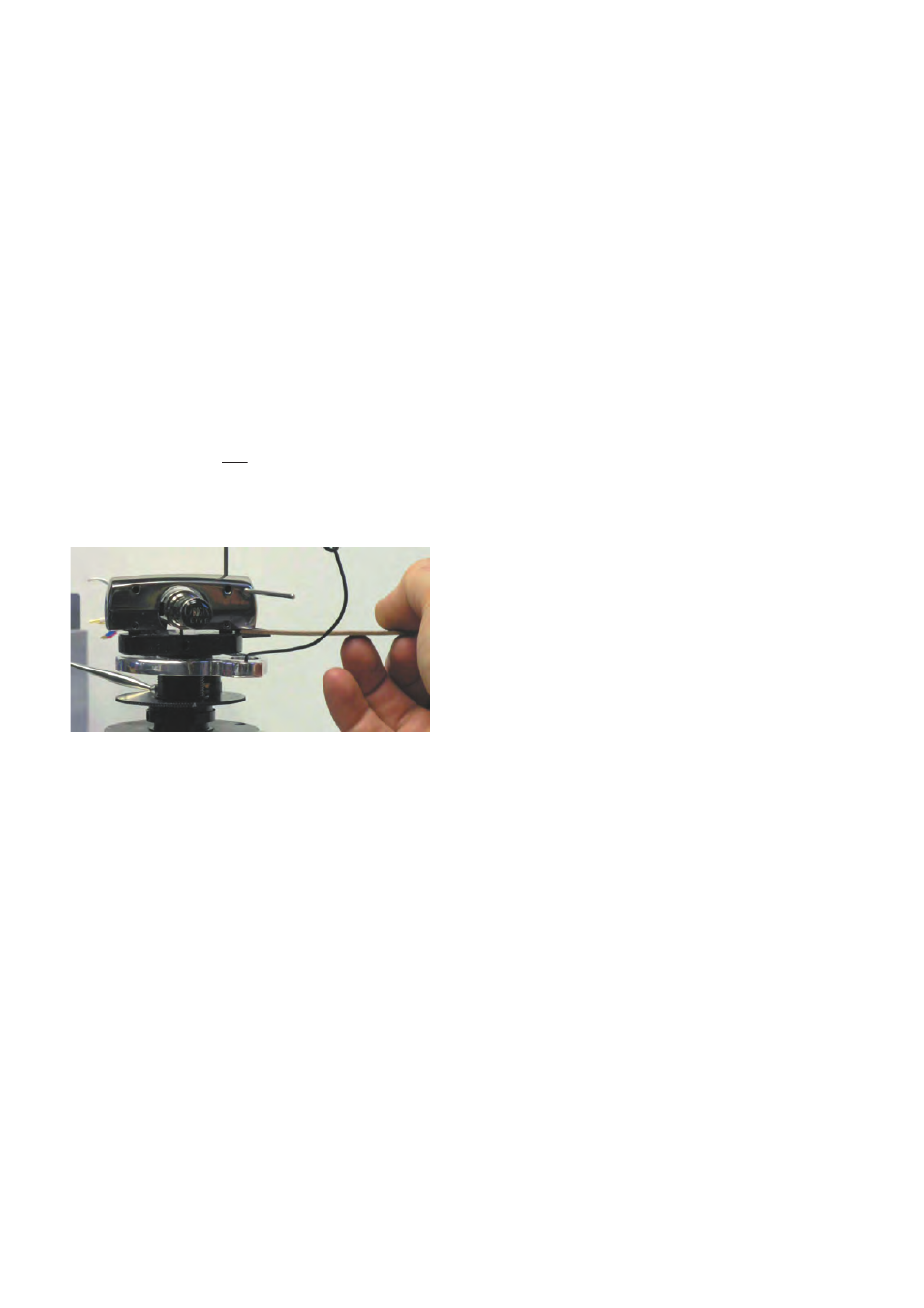

A fi nal check is to confi rm that you can just insert the

cork strip marked “gauge” into the gaps as shown on

photo 4 & photo 5. Th e cork strip is 1.5mm thick.

Note:

there are minor protrusions from underside of the

yoke - the cork strip should be between the protrusion

and the turret plate when measuring the 1.5mm gap.

WARNING - do not wind to a point where you meet

resistance. If the points are wound in too far (clockwise)

they are forced hard against the jewelled cup and can

easliy splinter the hardened points or fracture the

sapphire jewelled cups.

CHECK THAT ALL IS WELL - Th e stylus down force should be consistently accurate

to within plus or minus 0.05 grams. Higher deviations indicate that the bearing has been

damaged or incorrectly adjusted.

To check consistency, measure the stylus down force over a succession of 10 or so movements

of the arm into the arm clip and then onto a stylus force gauge. It is best to use a digital force

gauge for this as a “balance” type can give inconsistent readings with errors of up to 0.5 grams

Th ank you for purchasing an Origin Live arm. Enjoy getting closer to the original sound and

enter the heart of your music. We hope to serve you in the future.