Origin Live Enterprise C User Manual

Page 4

Page 4

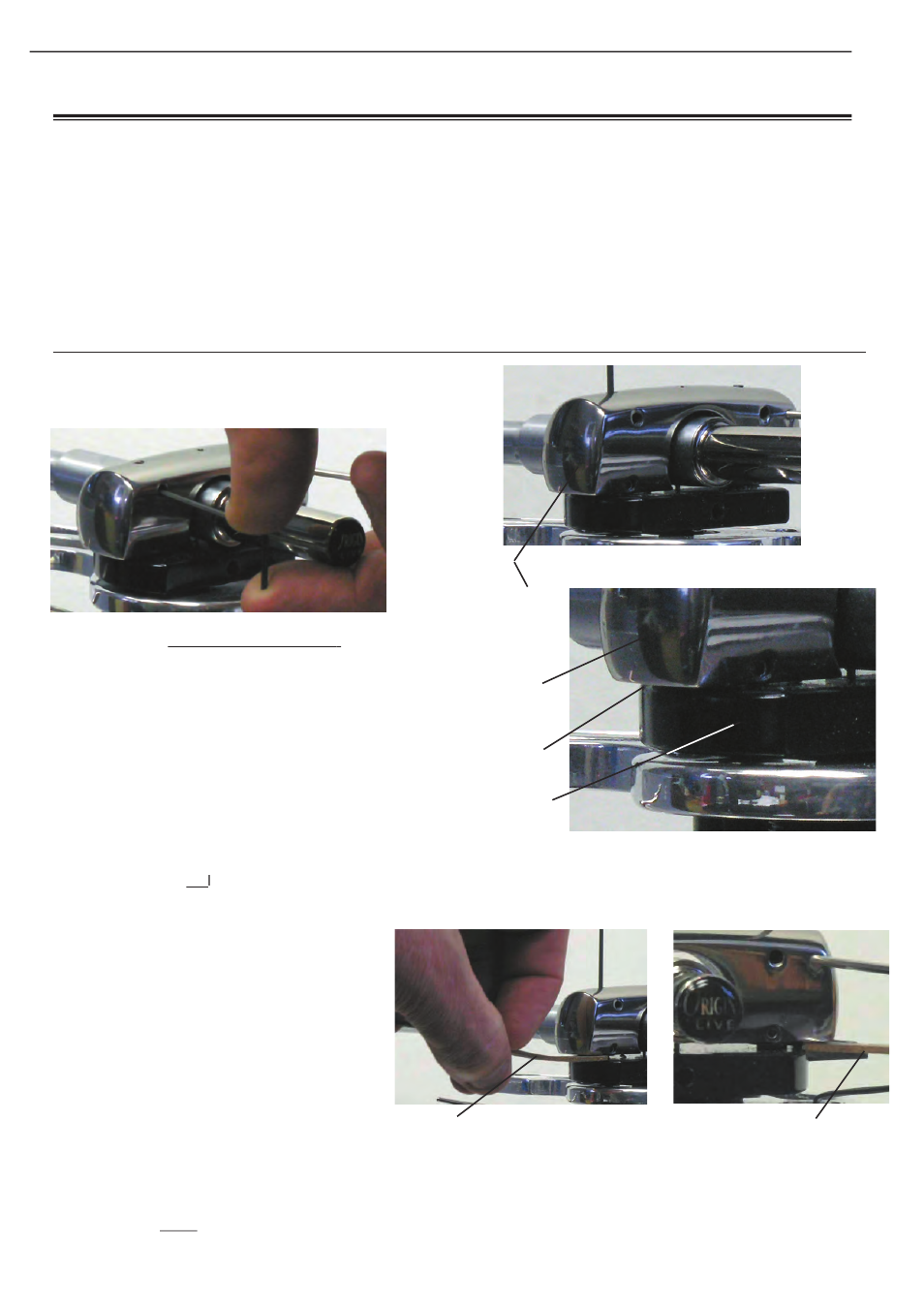

Re-setting the dual points if original settings are lost

Place the arm in the arm clip

to ensure the

arm is roughly level along its length.

Now turn the 2 azimuth pivot adjuster screws

anti-clockwise to lower the yoke till it touches

the turret plate and then unwind the screw a

further turn.

Next wind in each adjuster screw (clockwise)

to the stage where it just

just starts to lift the

just

just

yoke off the turrret plate. Th is is what will be

referred to as the “ground datum position” .

NOTE: Th ere are thin protrusions on the

underside of the yoke under the pivot screw

positions - Th e underside of these protrusions

are considered to be the underside of the

yoke.

Th ere are two methods of achieving this

“ground datum position”. Th e fi rst is to push

down on the yoke hard with the thumb of

one hand. At the same time wind a pivot

adjuster screw clockwise. At fi rst the screw

will be relatively free but when it meets the

jewelled cup and starts lifting the yoke against

the force of your thumb the resistance to

turning will increase signifi cantly. Th e point

where resistance starts is the ground datum.

Ensure that the 2 Azimuth clamping screws

Azimuth clamping screws are

slack by winding them anti-clockwise approx 1

turn

Enlargement

photo of “gap”

area

YOKE

NO GAP BETWEEN

YOKE & TURRENT

PLATE

TURRET PLATE

1 TURN ON THE AZIMUTH ADJUSTER

SCREW = 0.5MM INCREASE RISE OF YOKE

PHOTO 4

CORK STRIP INSERTED ON LEFT

SIDE IN 1.5MM GAP BETWEEN YOKE

AND TURRET PLATE

SUMMARY OF PROCEEDURE Th e headshell is

factory set to be perfectly parrallel to the bottom face of the

yoke in terms of rotation (azimuth). We therefore use the

bottom face of the Yoke as one key reference - i.e. if the

yoke is level then we know the headshell azimuth is correct

(azimuth is the rotation of the headshell relative to vertical).

Th e aim of the adjustment described below is to end up

with the bottom face of the yoke level and 1.5mm above

the top surface of the semi-circular yoke plate

directly

underneath it. Note: Th e yoke plate is perfectly level.

A summary of the proceedure described below is fi rstly to

lower the yoke so that its bottom face (protrusions) nearly

rests on the turret plate. Th is gives a rough reference point

to start from. Next, raise the yoke exactly 1.5 mm by

turning the azimuth adjuster screws 3 turns. Check yoke is

level and if not then fi ne adjust it, using the cork strip till

exactly level on both sides of the yoke.

DETAILS FOR SETTING UP BEARING POINTS

CORK STRIP INSERTED ON

RIGHT SIDE IN 1.5MM GAP

BETWEEN YOKE AND TURRET

PLATE

PHOTO 5