Origin Live Enterprise C User Manual

Specific instructions, Dual pivot bearing design – why, Handles like a conventional gimballed arms

Dual pivot bearing design – why?

The Enterprise arm is a performance leader by virtue of it’s

innovative dual pivot bearing on the horizontal axle (which governs

the arms vertical movement). This design is similar in many

respects to uni-pivot designs – low friction and high decoupling

which give excellent defi nition and transparency. However

uni-pivots can be fi ddly to set up and because of their relative

instability exhibit a mediocre bass performance. Dual pivot design

has all the advantages of uni-pivots but none of the drawbacks.

Vertical movement of the arm is handled by the dual pivot and

horizontal movement by our usual highly specifi ed conventional

bearings.

Handles like a conventional gimballed

arms

You should handle the arm in exactly the same way as a

conventional gimballed arm. In other words you do not need

to worry about setting up azimuth and balancing the arm. The

azimuth has already been set, such that the headshell is parallel to

the arm mounting surface. We strongly recommend that you never

adjust the factory setting even though it is possible via the pivot

screws. Correct azimuth setting is tricky at the best of times and

unless an extremely careful record is kept on the original factory

settings the arm will probably end up not working correctly. If

in trouble see technical support on our web site www.originlive.

com/troubleshooting_tonearms.htm

Having said this it is recommended to slacken off the azimuth

clamping screws NOT the azimuth adjuster screws. Slackening

the clamping screws has the effect of increasing the performance

signifi cantly.

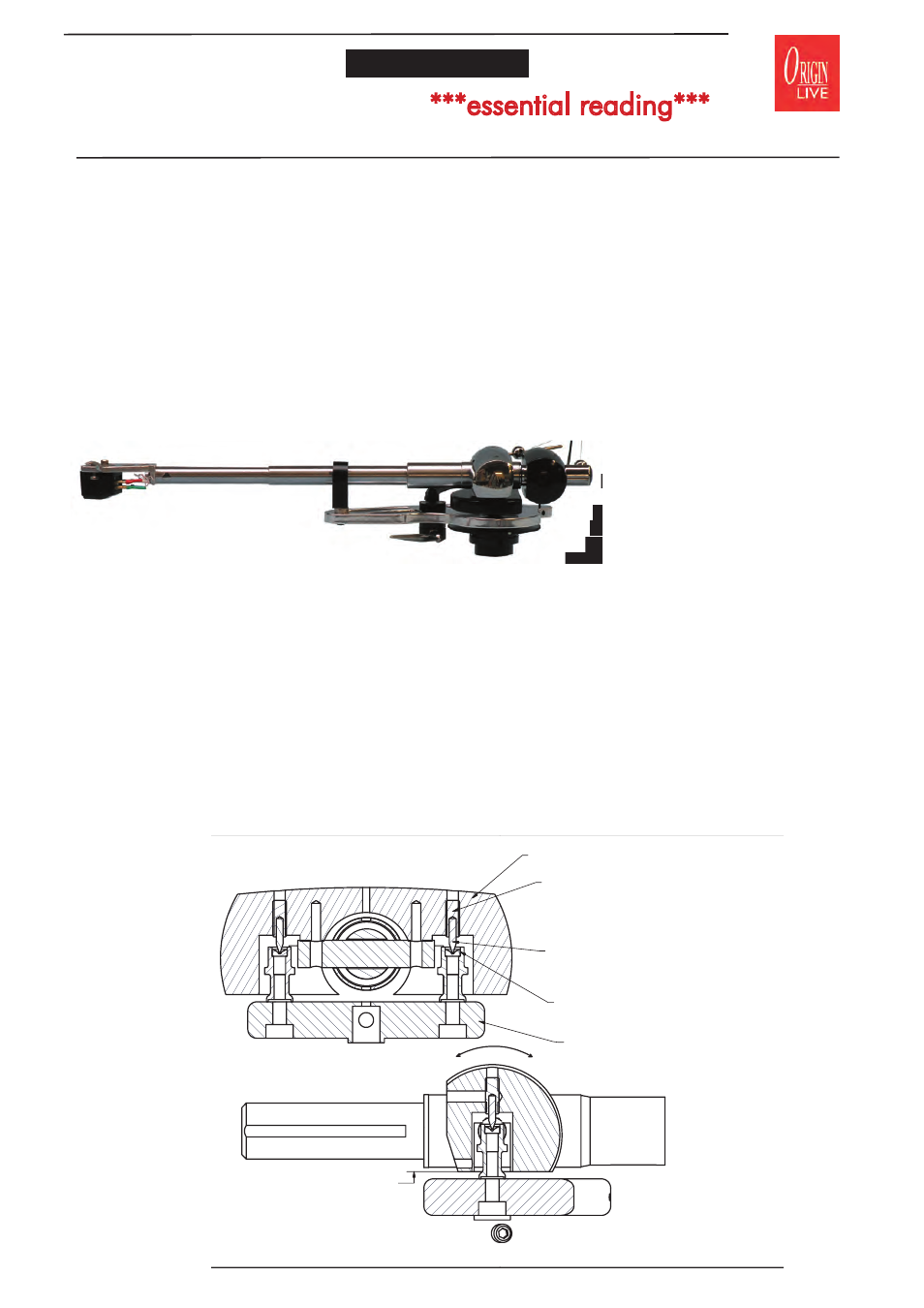

Understanding dual pivot

The below illustration shows the dual pivot bearing to give an

understanding of why the horizontal axle is free to move a little in

all directions except downwards. This may be a little disconcerting

until you become confi dent of the inherent virtues delivered in

performance. It is also reassuring to know that the arm cannot be

knocked off it’s bearings or come loose in any

way. You can turn the arm upside down and

nothing will fall off as it would in the case of

a uni-pivot!

The pivot bearings are designed to reduce

friction to the absolute minimum practical

level. In doing this there is a fi ne balance to

achieve both a long lasting, robust design and

realizing the potential of extremely low friction. In practice this

means that the arm must have a slight degree of movement due

to a rounded tungsten point in a shallow radiused (nearly fl at)

sapphire jewelled bearing cup. The alternative to this is a very

sharp, potentially fragile point in a deep v shaped cup – this

would certainly restrain the movement of the point but would also

increase friction.

The pivot points will “self centre” by sliding into the bottom

of the shallow low friction cup. However the fi nal resting place

of the point in the cup may vary by 0.01mm or so. This would

not be noticed without the use of a very accurate digital stylus

force gauge – as the pivot position changes fractionally so can the

tracking force by up to 0.02 grams. In practice this has no effect on

performance and is also common among certain unipivot designs

with very low friction bearings.

(

)

PIVOT POINT IN THREADED SCREW

Adjusts azimuth

YOKE RIGIDLY FIXED TO ARM TUBE

TURRET PLATE

- rotates freely on conventional bearings

ENTERPRISE FRONT VIEW OF DUAL

PIVOT ARRANGEMENT

SIDE VIEW OF DUAL PIVOT

ALLEN SCREW HOLDING PIVOT POINT

rotating clockwise raises this side of the yoke.

Movement

NOTE

It is not nessecary to understand

these diagrams but they are

included for information only

SAPPHIRE CUP BEARING

When arm is horizontal - bottom surface

of the yoke should be roughly parrallel

with turret plate in side view.

This is set at factory and only held by

friction fit which can be forced out of

alignment by mishandling or transit.

Cork strips are inserted to prevent

movement occuring in transit.

Specific instructions -