Troubleshooting guide – Losi LOSB0222T3 Manual User Manual

Page 5

EN

EN

Troubleshooting guide

Problem

Possible Cause

Solution

Vehicle doesn’t operate

Battery not charged or plugged in

charge battery/plug in

Receiver switch not “On”

Turn on receiver switch

Transmitter not “On” or low batteries

Turn on/replace batteries

Motor runs but rear wheels

don’t move

Pinion not meshing with spur gear

Adjust pinion/spur mesh

Pinion spinning on motor shaft

Replace pinion gear on motor

Slipper too loose

check & adjust slipper

Transmission gears stripped

Replace transmission gears

check and replace drive pin

Steering doesn’t work

Servo plug not in receiver

check if plug in/in all the way

Servo gears or motor damaged

Replace or repair servo

Won’t turn in one direction

Servo gears damaged

Replace servo

Motor doesn’t run

Motor plugs loose

Plug in completely

Motor wire broken

Repair or replace as needed

ESc damaged

contact Horizon Hobby Product Support

ESc gets hot

Motor over-geared

Use smaller pinion on motor

Driveline bound up

check wheels, suspension, and transmission

for binding

Poor run time and/or sluggish

acceleration

NiMH pack not fully charged

Recharge battery

charger not allowing full charge

Try another charger

Slipper slipping too much

check/adjust slipper

Motor worn out

Replace motor

Driveline bound up

check wheels, transmission for binding

Poor range and/or glitching

Transmitter batteries low

check and replace

Transmitter antenna loose

check and tighten

Vehicle battery low

Recharge or replace

Loose plugs or wires

check motor and power plugs

Slipper won’t adjust

Drive pin missing in shaft

Replace drive pin

Spur gear face worn out

Replace spur gear and adjust slipper

Chassis Tuning

The following are simple adjustments and easily maintained settings to assure proper operation and

performance. It is advised when making any adjustment that you do so in small increments and always

check for other parts of the chassis that are affected.

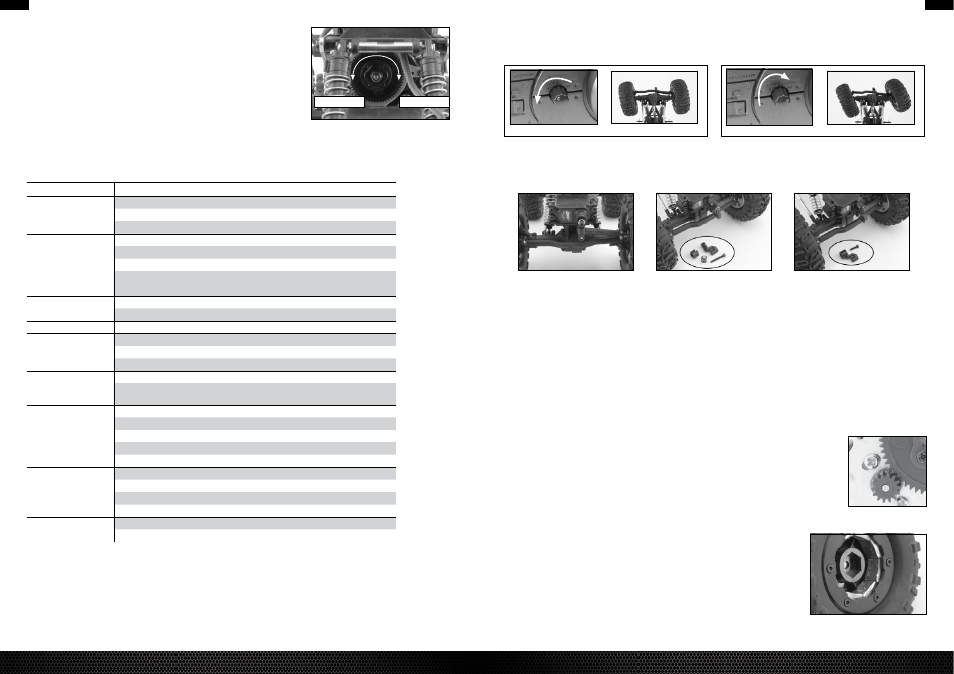

Slipper Adjustments

The Mini-Rock crawler is equipped with a slipper device offering both traction control and protection

for the transmission. The slipper is primarily used to help absorb sudden impacts on the drivetrain or

when using more powerful aftermarket motors and/or battery packs. Additionally, it can be used to

smooth out the flow of power to the wheels. Adjustment is made by turning the 3mm adjustment nut

clockwise (to the right) to reduce the slip, or counterclockwise (to the left) to increase the slip. As you

punch the throttle, the slipper should slip no more than an inch as it accelerates. With the included

motor and battery pack it should slip just a little. Make sure you replace the gear cover before running.

INCREASE SlIP

dECREASE SlIP

Steering Rate

Your transmitter is equipped with a steering rate control to the left of the steering wheel. This advanced feature, usually found only on competition-type

radios, allows you to adjust the amount the front tires move when you turn the steering wheel.

Steering Servo Saver Removal

The Mini-Rock crawler steering servo comes with a servo saver installed. As your rock crawling skills improve, we have included a steering arm that

eliminates the servo saver. Although this setup provides more precise steering, it does put your servo gears at risk for breakage. Use caution when the

steering servo is under severe loads.

Full Rate

Less Rate

1. center servo saver arm

2. Remove servo saver arm assembly from

the servo. Remove the steering ball stud

and install into solid servo arm.

3. With servo output shaft still centered,

install solid servo arm with the shorter

screw supplied and attach steering linkage.

Changing the Pinion gear/gear Ratio

Before you change the pinion gear, ask yourself why you are doing it. In general, if you change to a larger pinion, the wheel speed will increase but you will

see less acceleration and run time. This would only be advisable for low traction climbs. changing to a smaller pinion will give you quicker acceleration and

possibly a bit longer run time but a little less wheel speed. This would be good for high traction rock climbs. The pinion on the Mini-Rock crawler offers the

best balance of both. To change the pinion, remove the gear cover, loosen the motor screws and slide the motor back. Use the included 1.5mm allen wrench

to loosen the pinion setscrew. Place the new pinion on the end of the motor shaft and, using the flat of the pliers or a similar flat tool, push it on to the same

position as the one removed. See Setting the Gear Mesh below. Your Mini-Rock crawler comes equipped with a 14-tooth pinion, which provides an overall

ratio of 86:1. If you increase the pinion size to a 15-tooth gear, the ratio will change to 80:1 To decrease the pinion size to a 13-tooth will be 92:1.

NOTICE:

When running aftermarket motors, check with the motor manufacturer for correct gearing. Never over-gear the motor as it can cause overheating,

damaging it and the speed control.

Setting the gear mesh

The motor screws should be slightly loose. Slide the motor forward allowing the pinion gear to mesh with the spur gear. Snug

(not tight) the bottom motor screw and try rocking the spur back and forth. There is a slight bit of movement before the motor

is forced to turn over. If not, pull the top of the motor back slightly and recheck. If there is too much slop between the gears,

push the top of the motor forward. When set properly, the wheels can be spun forward freely with very little noise. Make sure

to tighten both motor screws and replace the gear cover before running.

Tuning Tips

Weight: Adding weight to the front wheels of the Mini-Rock crawler will help increase traction and lower the over center of

gravity. Using the LOSA99201 Self Stick weights, carefully cut each piece in half and place inside the wheel as pictured. It is

important that the wheel weights be evenly placed inside the wheel to ensure that it is balanced.

Shock oil and Springs

The Mini-Rock crawler shocks are filled with Losi 30wt shock fluid. By switching to thinner shock fluid, the Mini-

Rock crawler will have more traction, quicker weight transfer and softer dampening. Doing the opposite will cause

the Mini-Rock crawler to react more slowly to input and have slower weight transfer. Adjusting these settings will

help adapt the Mini-Rock crawler to your conditions. Please note, the Mini-Rock crawler comes from the factory

with a stiffer rear spring to help minimize “Torque Flex” often found in 4WD driver rock crawlers.

Cleaning

Performance can be hindered if dirt gets in any of the moving suspension parts. Use compressed air, a soft paintbrush, or toothbrush to remove dust or dirt.

Avoid using solvents or chemicals as they can actually wash dirt into the bearings or moving parts as well as cause damage to the electronics.

9

8

LOSI MINI-ROCK CRAWLER • INSTRUCTION MANUAL

LOSI MINI-ROCK CRAWLER • INSTRUCTION MANUAL