Losi LOSB0125 User Manual

Page 19

19

Engine is hard to turn over:

1. If the engine is hard to turn over make sure the battery in

your Spin-Start is fully charged.

2. The engine may be flooded. Remove the glow plug, turn

the model upside down over a rag and turn the engine

over. Raw fuel should spray out of the glow plug hole.

Replace the glow plug making sure you replace the small

copper gasket that goes on it.

3. If the engine is still hard to turn over there may be internal

damage. See your hobby dealer or call Horizon Hobby

Product Support for help.

Engine tries to start but will not run:

1. Check the glow igniter as noted above.

2. Engine may be loaded up with excess fuel inside. Count

to 5 before trying to start. If starting improves repeat until

the engine runs and idles.

3. Engine may be overheated. Let cool, open high-speed

needle 2 hours and retry.

4. If the fuel has been left open or is over 6 months old try

replacing the fuel including that in the fuel line.

5. Read “Engine Tuning” section for more help.

Filling/Changing the Shock Fluid

1. Hold the plastic shock end in one hand and slide the

spring cup at the bottom up compressing the spring. While

holding the compressed spring between your fingers, slide

the spring cup off the shock shaft through the open slot in

the cup. Remove the spring and set it aside.

2. While holding the shock body with the shaft pointing up,

turn the plastic hex of the shock cartridge (where the shaft

enters the shock) counter-clockwise until it and the shock

shaft can be removed.

3. If changing the fluid turn the shock body upside down

over a garbage can allowing all of the fluid to escape. This

is a good time to clean the inside of the shock body with

LOSI Nitrotec spray cleaner (LOSA99217).

4. Fill the shock body to the bottom of the threads inside the

shock body with LOSI 35wt.shock fluid (LOSA5225) or if

changing, the new weight fluid.

5. Insert the shaft/cartridge assembly with the shock piston

against the cartridge into the shock body. Slowly tighten

(turn clockwise) the cartridge about two full turns only.

7. With the cartridge still slightly loose, slowly push the shock

shaft into the shock body. Fluid will escape around the

threads. This will bleed the excess fluid out of the shock.

Once the shaft is all the way down, tighten the shock

cartridge finger tight.

8. With the shaft assembly still pushed all the way in, secure

the cartridge by tightening with pliers or a 7/16-inch

wrench approximately 1/8 to 1/4 of a turn. There should

be no air in the shocks as you move the shaft in and out.

If there is you need more fluid. If the shock does not

compress all the way, the shock has too much fluid and

you need to loosen the cartridge 1/2 turn and repeat

starting at step 7.

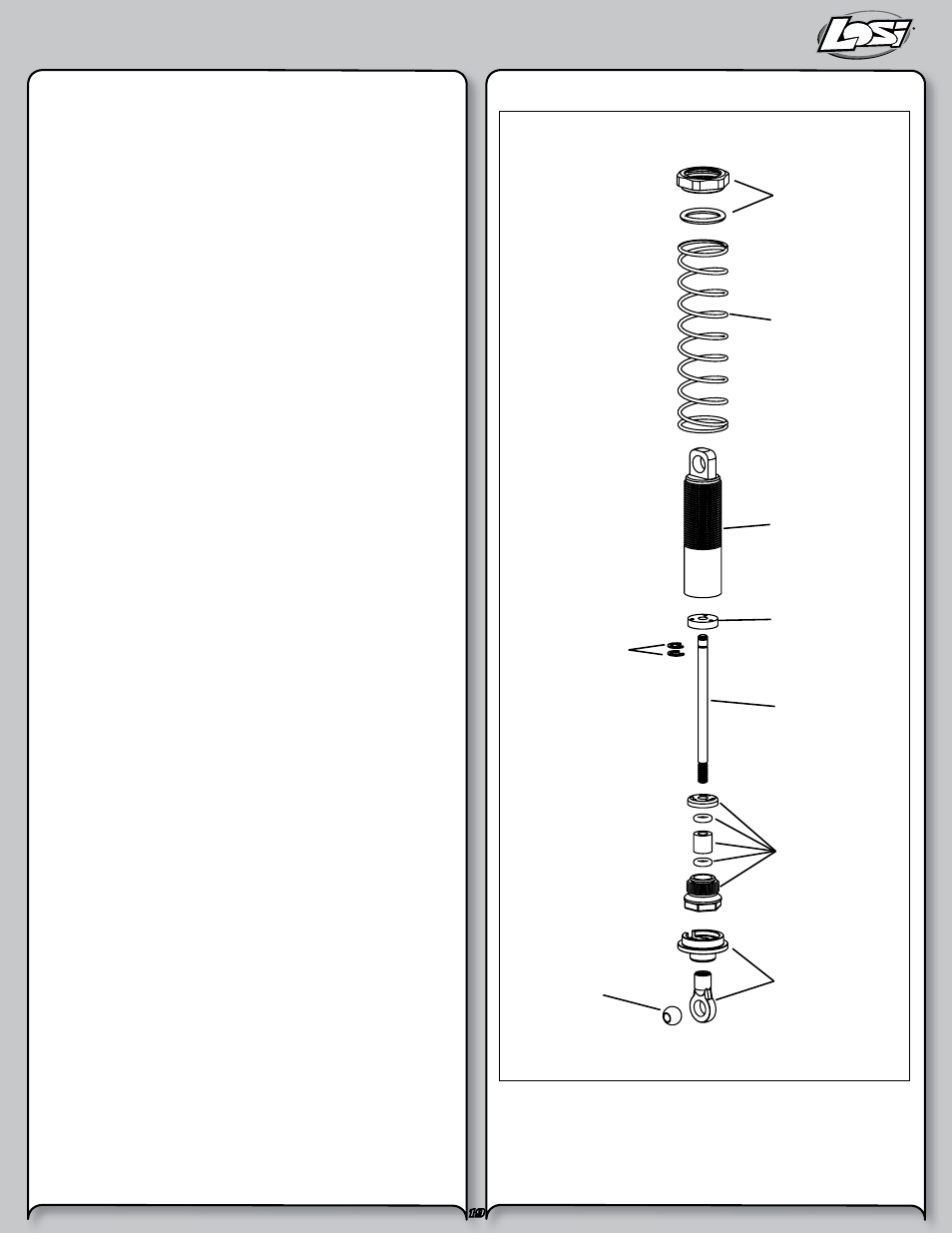

Shock Diagram

A5051

A5155

or

A5154

A5073

A5074

A501

A5015

A5079

A2006

A6100