Losi LOSB0125 User Manual

Page 10

10

About Glow Plugs

The glow plug is like the ignition system in your automobile.

The coiled element in the center of the plug glows red hot

when connected to a 1.5-volt battery (located in the igniter).

This is what ignites the fuel/air mixture when compressed in

the cylinder. After the engine fires, the heat generated by the

burning fuel keeps the element hot. Common reasons for the

engine not starting are the 1.5-volt battery being weak, the

glow plug being wet with fuel, or the element burned out. Use

a spare glow plug to check the igniter. If the igniter makes the

element glow, remove the plug from the engine to check it in

the same manner. A wet glow plug means there is excess fuel in

the engine. To eliminate this, put a rag over the head and turn

the engine over a few seconds with your Spin-Start. Reinstall

the glow plug, making sure you have the brass gasket on it. The

engine should now start.

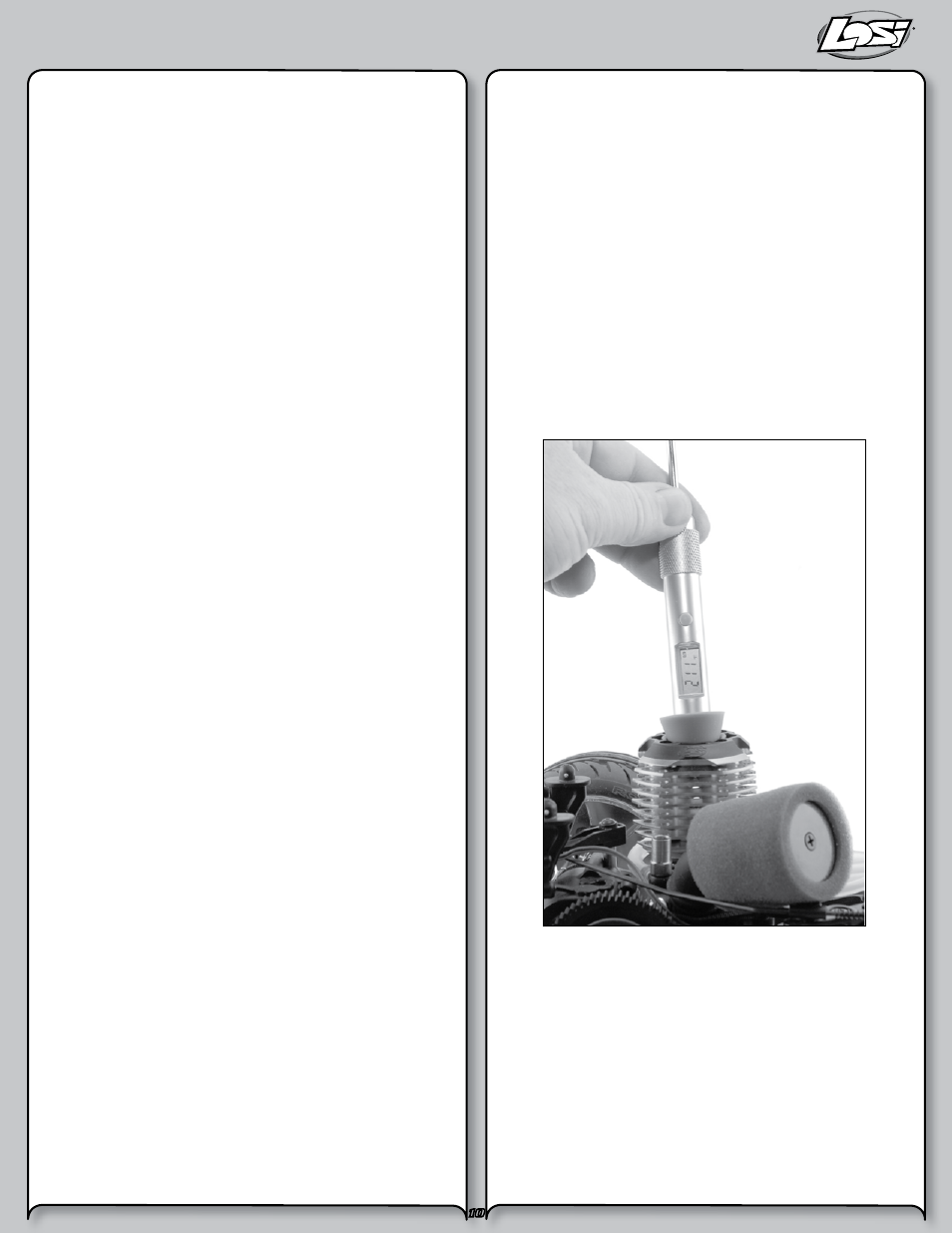

Testing the Temperature

The ideal operating temperature for an engine will vary with

the air temperature but in general it should be in the 190° to

230°F (88 to 110° C) range. Since the Speed-NT has a head

protector you will have to rely on your ears or preferably

a remote temperature gauge like the Losi Temp-Tuner

™

(LOSA99171) which incorporates an infrared temp sensor/

gauge and a handy carburetor tuning screwdriver. If the

engine is overheating turn the high-speed needle out (counter

clockwise) at least two hours. If the engine is running rich

(below 190° F) turn the high-speed needle in (clockwise) one

hour at a time until it is running within the normal range.

Low-Speed Adjustment

The low-speed adjustment affects the idle and slightly-off-idle

performance. The optimum setting allows the motor to idle

for at least 8−10 seconds. The model should then accelerate

with a slight amount of sluggishness and a noticeable amount

of smoke. The simplest way to check this is to make sure the

engine has been warmed up and let the engine idle for 8−10

seconds. If the low-speed mixture is so far off that the engine

won’t stay running that long, turn the idle stop screw clockwise,

increasing the idle speed. With the engine at idle, pinch and

hold the fuel line near the carburetor, cutting off the flow of

fuel, and listen closely to the engine rpm (speed). If the low-

speed needle is set correctly, the engine speed will increase

only slightly and then die. If the engine increases several

hundred rpm before stopping, the low-speed needle is too rich.

Lean the mixture by turning the needle clockwise one hour and

trying again. If the engine speed does not increase but simply

dies, the needle is too lean and needs to be richened up by

turning the needle counterclockwise one hour before trying

again. After you have optimized the low-speed setting, the

engine will probably be idling faster. You will have to adjust the

idle stop screw counterclockwise to slow the engine idle speed

down. The engine should accelerate at a constant pace without

hesitating.

High-Speed Adjustment

After initial acceleration, the engine should pull at a steady rate

while maintaining a two-stroke whine and a noticeable trail of

smoke. If the engine labors and is sluggish with heavy smoke,

the mixture is too rich and needs to be leaned by turning the

high-speed needle clockwise in one-hour increments until it

runs smoothly. If the engine isn’t smoking or starts to die after

acceleration, it is too lean and you must richen the mixture by

turning the needle counterclockwise. Don’t be confused by

the sound of the engine and the actual performance. A leaner

mixture will produce an exhaust note with a higher pitch but

this does not necessarily mean improved performance, as the

engine is on the verge of overheating and may incur possible

damage. Ideally you want to run the engine so that it is on

the slightly rich side of optimum. This will give you the best

combination of speed and engine life.

CAUTION

: The engine

is too lean and overheating if it accelerates rapidly with a

high-pitched scream then seems to labor, stops smoking, or

loses speed. This can be caused by the terrain, atmospheric

conditions, or drastic altitude changes. To avoid permanent

engine damage,

immediately

richen the mixture by turning

the high-speed needle counterclockwise at least “two hours”

and be prepared for further adjustments before running any

more.

Note

: The normal operating temperature as seen on

your radio screen should be in the 190 to 220° F (88 to 105° C)

range.