Losi LOSB0105BD User Manual

Page 18

Adjusting Gear Mesh:

Incorrect gear mesh is the most common cause of stripped spur

gears. To set the gear mesh, one method is to cut a narrow strip

of notebook paper and thread it in between the gears. Loosen

the motor screws and slide the motor and pinion gear into the

spur gear. Retighten the motor screws and then remove the strip

of paper. Or you can loosen the motor and carefully slide the

motor leaving a small amount of backlash (play) between the

spur and pinion gears. It should not be tight and if you look

up-close there should be slight movement of the spur before

contacting the teeth on the pinion gear.

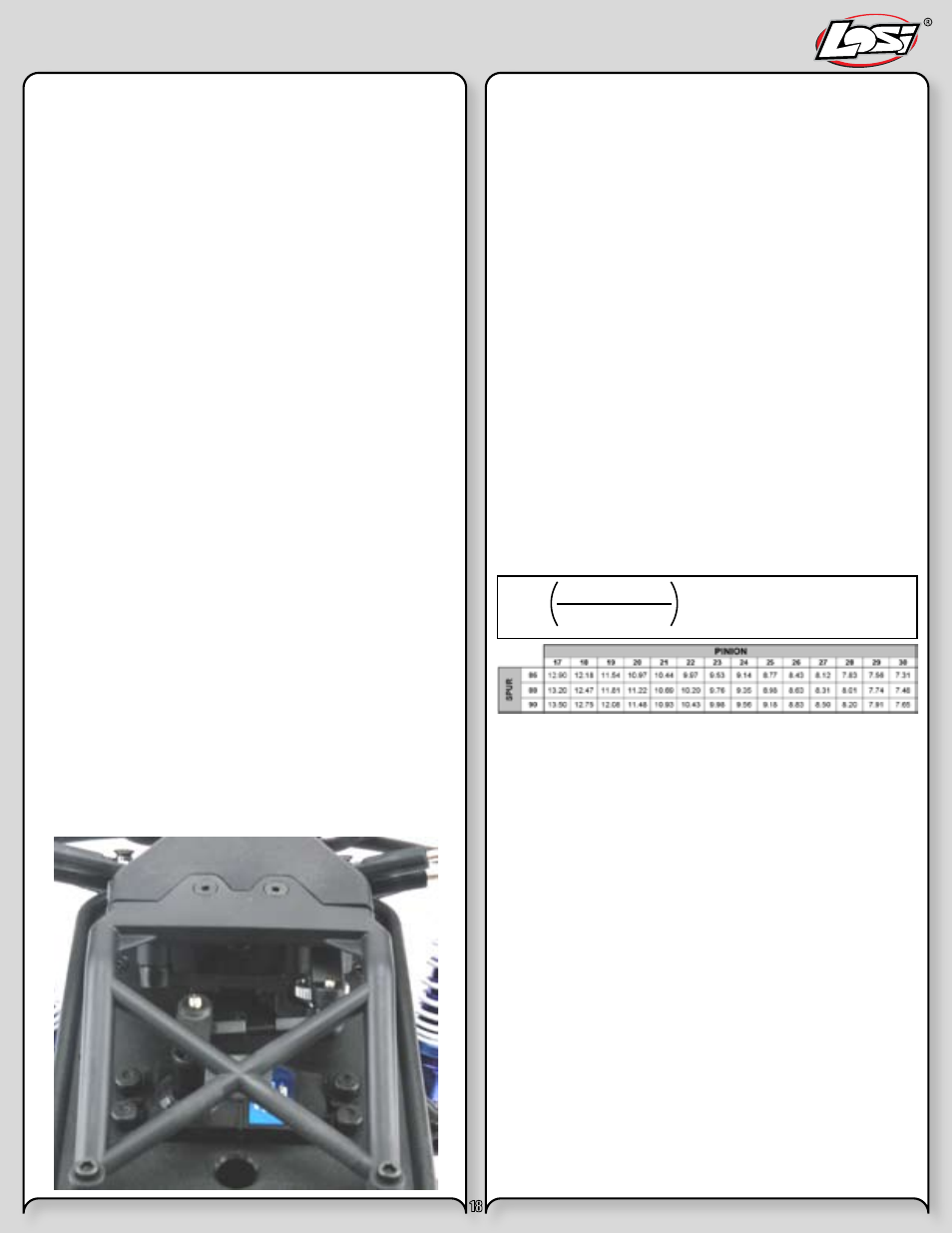

Gear Ratio:

Changing the gearing provides you a quick and easy way to tune

the 1/10 Strike SCT. Use the temperatures of both the motor

and your battery pack as a guide to gearing to your environment.

When the Motor is above 160-170 degrees Fahrenheit or the

batteries are above 125-135 degrees Fahrenheit, these are both

strong indications that you should drop the pinion size smaller.

This would be a lower gear ratio or larger number, for example

from 11.25 to 12.40. Going up a pinion size is called gearing

higher or a small number, for example 11.25 to 10.6, and will

increase power consumption and allow more speed.

Use the following formula to calculate the overall ratio for

combinations not listed on the gear chart:

When using higher gear ratios, it is extremely important to

monitor the temperatures of the battery and motor. If the battery

is extremely hot, and/or the motor is so hot that you cannot

touch it, most likely you are over geared and drawing a lot of

current. The gear combination that comes on the 1/10 Strike

SCT (20-tooth pinion / 90-tooth Spur) provides the power for

running through mowed grass and off-road dirt surfaces.

Storage:

When you are through running the model for the day,

•

Blow it off with compressed air or use a soft bristled paint

brush to dust off the vehicle.

•

Always disconnect and remove the battery from the model

whenever the model is stored. If the model will be stored

for a long time, then also remove the batteries from the

transmitter.

Tuning the Chassis of the 1/10 Strike SCT (CONT’D)

Battery Position:

This is a critical adjustment that is often overlooked but

can be very useful. Start by running the battery spaced in

the back (standard setup with 6-cell battery pack). Having

the battery in the back can improve rear traction on

slippery surfaces and steering response. Having the

battery back too far can cause the rear end to swing

through turns on some tracks and “dump” the rear end

causing instability issues. This is a result of having the

weight too far back. The 1/10 Strike SCT comes equipped

with foam battery spacers to accommodate different size

battery packs.

Wheels and Tires:

The tires come pre-mounted with the vehicle and should

be checked to make certain they stay glued to the wheels.

The wheel spinning speeds can pull the rubber tire away

from the rim. When a tire or tires come loose from the rim,

you will notice the vehicle is hard to control.

Tip the vehicle on its side and using both hands to hold

one wheel at a time, use your thumb to press the tire

away from the rim. If you see a tire pull away for the rim,

use Losi Tire Glue (LOSA7880 thick or LOSA7881 thin) to

re-glue. It only takes a small drop of glue generally. Be

careful; this is CA-type glue and you do not want to glue

your fingers to the wheel and tire.

Use safety goggles when gluing tires.

Check the mounting of the tire periodically to ensure

proper performance and handling.

Steering Assembly:

Occasionally, check the steering assembly and you may

notice increased looseness. There are several compo-

nents which will wear out from use: tie rod ends (part

LOSB2015), the servo saver (part LOSB2356). You can

easily replace these components to restore factory

specifications.

Spur Gear Size

X 2.55 = Final Drive Ratio

Pinion Gear Size

18