Rebuilding/refilling the shocks, Tools needed – Losi LOSB0012LE User Manual User Manual

Page 7

Page 12

Page 13

Servicing the Transmission

The Transmission should also be cleaned and serviced periodically. All gears and shafts should be closely inspected for wear

and replaced if necessary. Always use a high-quality grease or lubricant to prevent premature wear and/or failure.

Removing the Transmission

1. Remove the gear cover.

2. Remove the throttle linkage from the carburetor and the brake linkage from the

servo arm.

3. Loosen the four motor mount screws (bottom of the chassis) and slide the motor back.

4. Remove 2-speed spur gears.

5. Remove the five transmission mounting screws and lift the transmission out.

6. Remove the outdrive and ten 5/64” cap head screws. Remove the transmission case half.

7. Regrease the gears and shafts, inspecting each for wear.

8. Replace any worn or failed gears.

9. Wipe out the inside of the gear case, removing any debris, old grease and foreign matter.

10. Check all ball bearings for free movement cleaning or replacing as necessary.

11. Reinstall gears on the shafts lubing with LOSA3066 or LOSA99203 Losi Assembly Grease.

12. Reassemble the transmission lubricating liberally with LOSA3066 or LOSA99203 or a similar

high-grade grease.

13. Make sure the setscrews in the outdrive cups are tightened (a locking compound is highly suggested).

14. Install the transmission in the chassis; reset the gear mesh by using a small piece of paper between the pinion and

spur gears, applying pressure while retightening the engine. Reconnect all linkages and connections as necessary.

14

3

5

1

6

*

2

Note: These four screws are

longer 2-56 x 3/4”

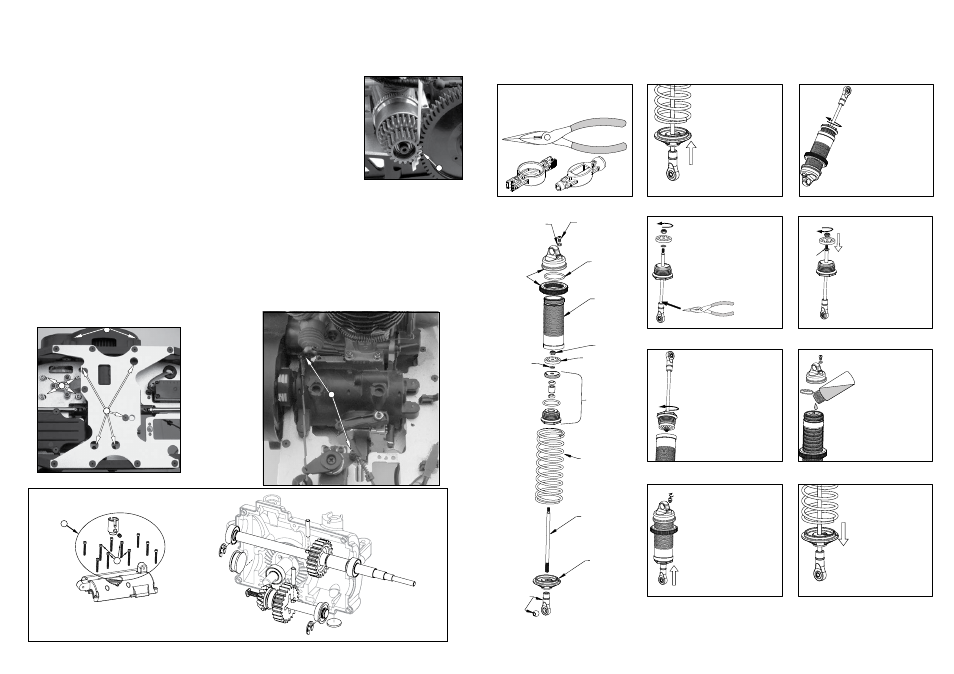

Rebuilding/Refilling the Shocks

Rebuilding/Refilling the Shocks

Step 1.

After removing the shock,

push up on the lower spring

cup and snap it off of the

shaft. Remove the spring.

NOTE: If you only wish to change

or fill the shock fluid, skip to step 6.

Turn the shock upside down

and, using the included shock

tool, remove the black shock

cartridge/shaft assembly from

the shock body by turning it

counterclockwise.

Step 2.

Step3.

Remove the 1/4" nut by turning it

counterclockwise. Remove the

piston and washer. Remove the

old cartridge. Put a drop of shock

oil on the shock shaft before

installing new shock cartridge.

Hold here with needle-nose pliers

Tools Needed

Step 4.

Install washer onto the shock

shaft until it stops. Slide the

shock piston onto the shaft

against the washer. Reinstall

1/4" nut and tighten by

turning it clockwise.

Be sure to

reinstall

washer

Step 5.

If you plan on completely changing

the shock fluid (suggested), dump

out the old fluid from the shock

body before reinstalling the

cartridge/shaft assembly. Pull the

shaft out so that the piston is next

to the cartridge and reinstall the

assembly into the shock body;

tighten in a clockwise direction.

Step 6.

Note: If you are just refilling your

shocks, be sure to use

Losi 30 wt Silicone

Shock Fluid (LOSA5224).

Remove the shock cap and the

small button head screw and

washer in the top of it.

Carefully fill the shock body with

fluid to the top. Move the shaft

up and down slowly to remove

bubbles. Top off with oil if needed.

Step 7.

Holding the shock upright, push

the shock shaft in slowly until it

bottoms out. While holding the

shock shaft in this position,

replace the small screw and

washer in the shock top. If fluid

leaks around the threads of the

cartridge, it is probably not

tight enough.

Step 8.

Slide the spring over the

shock body against the

shock adjuster nut. Slide

the lower shock cup onto

the shock shaft and snap it

onto the shock end being

sure that it seats on the

mount. Reinstall the shock.

"snap!"

"snap!"

"snap!"

A6234

B2900

B2815

B2876

B2820

B2840

B2900

B2875

B2948

B2840

B2900

B2900

B2840

LOSA5224

30 wt