5 - go to system start-up procedures, Ews, inc. / environmental water systems, 3 - plumbing line connections – Environmental Water Systems EWS 1354-2-P User Manual

Page 8: 4 - drain connections

EWS, Inc. / Environmental Water Systems

www.EWSWATER.com

4.4-8

1) LOCATE DRAIN PORT ON THE SIDE OF THE VALVE HEAD.

•

Screwed onto the drain port is a brass flow control housing. The flow control housing has a flow washer which determines

the flow rate in gpm from drain line.

2) DO NOT OVERTIGTHEN CONNECTIONS. IMPORTANT TO READ THE FOLLOWING:

•

Nominal drain line and drain size should be a minimum of 1/2”. **Backwash flow rates of these units (7 GPM) with drain line

exceeding 20’ in length require 3/4” line and drain. Install, non-restrictive, check valve in drain line, if drain water is expected

to flow over 5’ above the height of the drain port. Never restrict the backwash drain water flow.

•

Care must be taken when screwing in any connection to the flow control housing, not to crush piece and distort the flow

washer, crucial to the effective backwashing of the system. You may use any applicable adaptor or connector depending

on your drain line.

•

Hard piping of drain line: NO Heat, NO Torch, leave at least 12” between drain port and any solder joints. Solder joints before

connecting to drain port.

•

Use a union (or quick disconnect feature) for future servicing applications. Therefore, the system will require no replumbing.

•

Teflon tape is the only sealant to be used on any drain fitting.

3) LOCATE A SUITABLE PLACE TO DRAIN.

•

A suitable place to drain the backwash water must be available. Usually, into a drain or trap, or outside that has sufficient

percolation. You can be flexible or creative. Do not connect the backwash line to an air conditioning drain line. Do not freeze.

•

Air gap must be used, if connecting to a drain line or sewer trap, to prevent possible back siphoning into the tank.

•

Backwash is a mechanical way of turning over the filtration media. The discharge is only water and not a brine. The water

discharge can go anywhere, may be used, or recycled, and does not have the legal restrictions or issues of brine discharge.

1) IDENTIFY THE MAIN WATER SUPPLY.

•

Do Not Assume. You may have to perform “the old bucket test” to determine where the water is coming from.

•

Make sure the whole facility is on the line. Some cold water lines (kitchen, island, wet bar sinks, refrigerators, ice-makers)

may have been plumbed separately, if previously plumbed for softened (salts) water. You may have to recapture those

lines by replumbing that manifold. Or, capture the main water supply before the bypassed or “looped” away lines, usually

found at, or after, a main water shut off. However, some plumbing designs prevent this ideal installation. A sink (point of

use) filtration unit can be used for that missed location.

•

Hose bibs are unnecessary to capture unless required by consumer. Irrigation (which should tee-off prior to the home’s

main water supply) uses a lot of water and this connection should be discouraged. It puts an unnecessary burden on the

unit and the media.

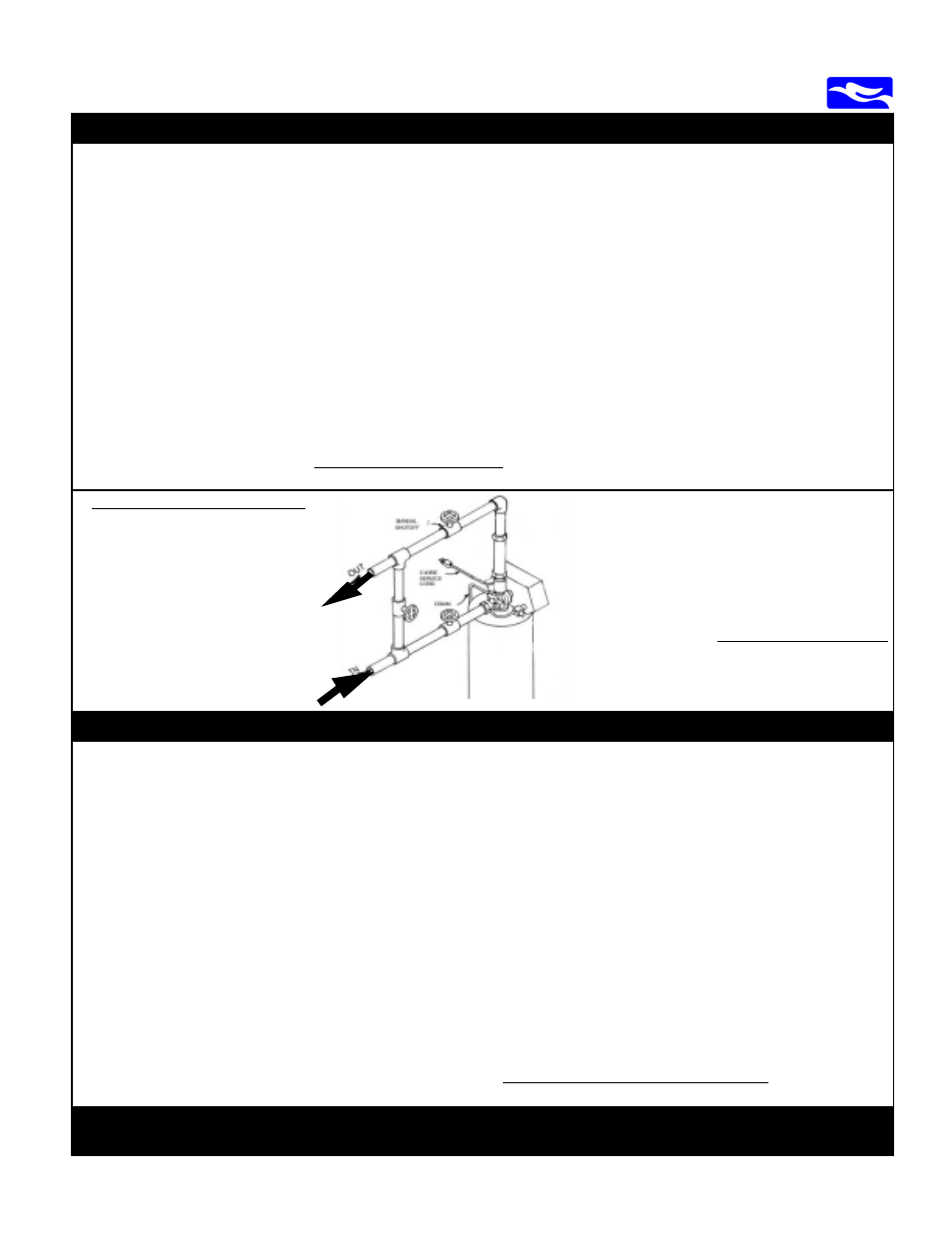

2) PLUMB INLET (supply) AND OUTLET (filtered) INTO THE UNIT AND PLUMB BYPASS VALVE BETWEEN.

•

Follow the directional arrows molded onto the valve body. See picture below for correct set-up.

•

Use unions (a quick disconnect feature) at the inlet and outlet pipe, as pictured, to allow future servicing of system without

cutting and replumbing

•

Use Ball Valves (preferred - easy to turn on/off) at inlet/outlet pipes and bypass, as pictured for proper installation.

•

NO Heat, No Torch; Leave at least 12” between the valve body and any solder joints. Solder joints prior to connecting to valve

body. Failure to do this could cause interior damage. Teflon tape is the only sealant to used on any of our fittings.

3) WARNING: ONCE PLUMBED, DO NOT TURN ON WATER, UNTIL YOU BEGIN START-UP PROCEDURES.

Note: If, recirculating pump on water heater, unplug pump before turning off water supply. Prevents damage to the pump motor.

3 - PLUMBING LINE CONNECTIONS:

5 - GO TO SYSTEM START-UP PROCEDURES

4 - DRAIN CONNECTIONS:

Inlet (supply) Side

Bypass

Valve

Drain

Electric

HF - High Flow

2750 Valve

Valve Cover: Black

NEMA 1 Rated

for resistence to

dust and moisture.

Hinged: left

Opens: from right

Controls: inside

DO NOT TURN ON WATER,

OPEN ANY VALVES OR

PLUG IN THE ELECTRICAL

UNTIL YOU GO TO THE

START-UP PROCEDURES

Back Side:

Front Side:

Drain:

3/4” MNPT

Connected (included) to:

Brass Flow Control

Housing with 7 GPM

Flow Restrictor

3/4” FNPT x 1/2” FNPT

Materials Needed for Drain:

1/2” copper x male adapter

1/2” union

1/2” (min) drain line

length to be determined

Materials Needed for Installation:

1” pipe length to be

determined

3 - 1” Ball Valves

2 - 1” Unions

See Drain Requirements

Union

Union

Outlet (filtered)

Side