Ews, inc. / environmental water systems, On-site assembly procedures, Adjusting backwash settings – Environmental Water Systems EWS 1354-2-P User Manual

Page 17

EWS, Inc. / Environmental Water Systems

www.EWSWATER.com

4.4-17

1) Take the empty tank and place it in your planned installed location.

2) Insert cap into the top of the riser, using the small riser cap, or tape the top of riser to prevent filling with media.

3) Place capped or taped riser into the center of the tank. The bottom of the riser has a lower screen which is

placed at the bottom of the empty tank. Make sure the bottom of the riser is seated at the bottom of the tank.

4) Place funnel at top opening of the tank. This will allow an easier fill of the underbed and filtration media.

5) Load tank with small heavy box labeled underbed, sand or pea gravel. Empty box completely.

6) Load all filtration media boxes. Empty all boxes completely. Materials are black and granular. Please prevent

any inhalation of media dust.

7) Lubricate the tank o-ring seal, which makes contact to the top of tank opening. Note: Use only a silicone lubricant.

8) Install the valve head by slipping upper screen (the cone at bottom of the valve head) over the top of the riser and

onto the tank. Hand tighten valve head onto tank by turning clockwise.

WARNING: BE CAREFUL NOT TO STRIP OR CROSS THE TANK THREADS.

8) The unit is assembled. Now - follow all instructions, pictures and schematics for proper Set-Up, Installation and

Start-Up of these systems.

ON-SITE ASSEMBLY PROCEDURES

Units with 2” valving or greater, include a complete guide on that valving and its exact set-up and installation.Start-up remains the

same; slow fill, valve settings, electrical, flushing/backwashing, and final service position.

ASSEMBLY PROCEDURES:

Unpack the Shipped Boxes and Identify the Following Components:

Important to Note: All Set-Up, Installation and Start-Up Procedures must be followed after assembly.

•

Tank

•

Riser only for Iron (-P) removal units and CWL Commercial units or Riser manifold with ICN’s for EWS

Commercial units. (find riser in separate box, in tank box, and/or within tank)

•

Filtration Media is a pre-measured kit and will come in 2 or more boxes and will also include the following:

•

underbed (small heavy box labeled sand, underbed or pea gravel)

•

small riser cap

•

funnel

•

Valve Head

•

Service Manual (additional information provided with systems using 2” valves and greater)

Due to the shipping weight of Iron Removal Systems and Commercial EWS/CWL Tank Units,

these units must be assembled on site.

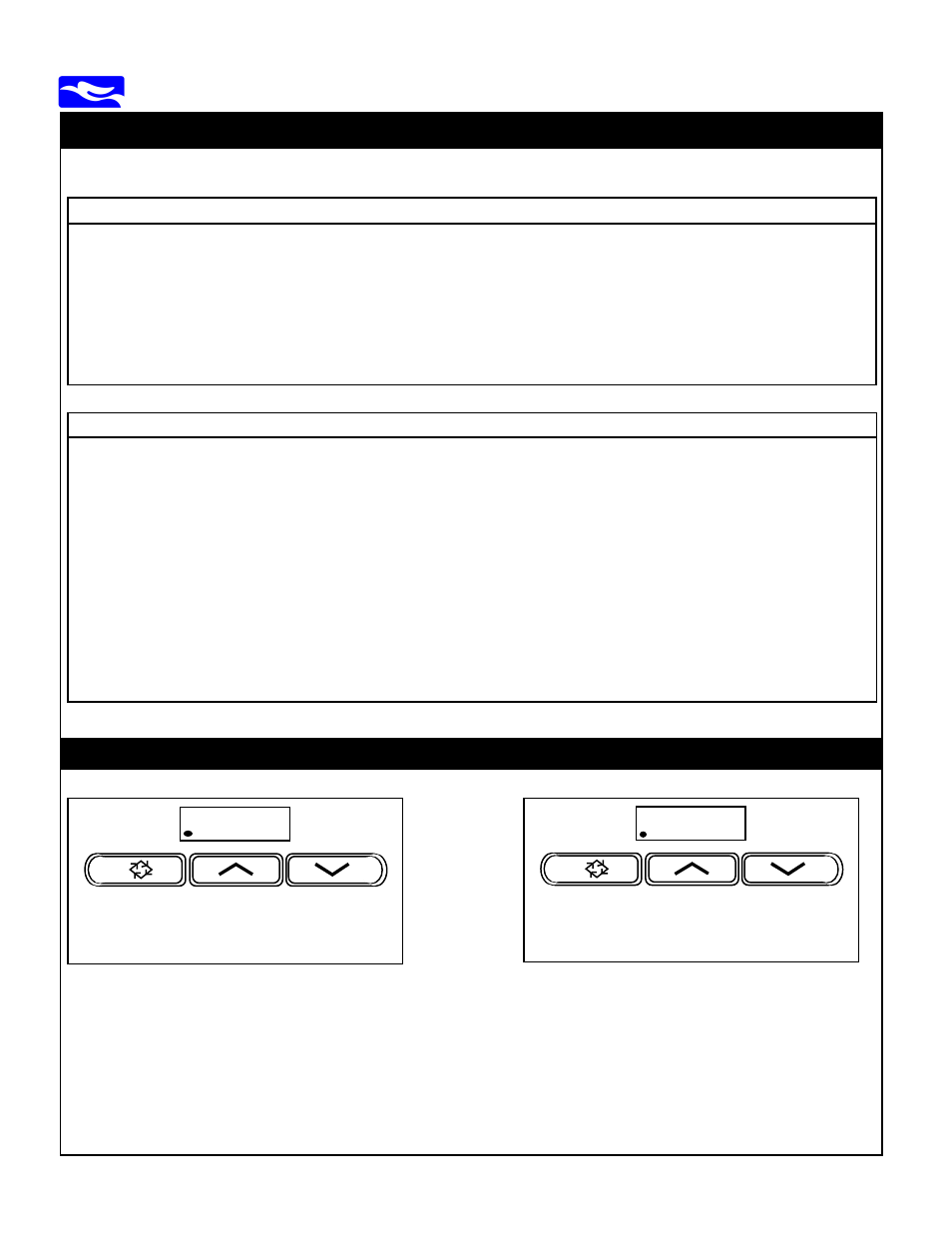

ADJUSTING BACKWASH SETTINGS

Flow

P.M.

Service

Program

A---3

Backwash Display

Step 1 - Backwash

Step 2 - Settling

Step 3 - Rapid Rinse

Flow

P.M.

Service

Program

12:00

Backwash Display

Step 1 - Backwash

Step 2 - Settling

Step 3 - Rapid Rinse

Increasing/Decreasing Backwash Frequency

Re-Setting the Time to Start Backwash

Step 1: To Enter the Programming Mode: Push and Hold, for 5 seconds, both the “Up” and “Down” buttons.

Program light will appear in lower left corner. Follow the steps below to make your adjustments.

Step 2: Once the program mode is entered, Push the

“Recycle” button until “A---3” appears in the display.

Step 3: Push “Up” or “Down” button to increase

or decrease the frequency the system will

backwash.

Note: 3 is the factory/normal setting, reset to 7 for vacation

(minimum 2; maximum 10) Remember to re-set to 3 upon return.

Step 2: When the program mode is entered, the display reads,

“12:00”. (“1:00 am for Iron) This is the Time of Backwash.

Step 3: Push “Up” or “Down” button to increase or decrease to

change the start of a backwash to the desired time of day.

Note: Adjust for larger valves that produce noise during backwashing.

Backwash takes 30 minutes to complete cycle. System is on bypass (not filtering)

during cycle. 2 or more units - must set each unit an hour apart.

Step 4: To Exit the Programming Mode: Push “Recycle” button to resume normal (Service Mode) operation.

Using these

Controls:

Backwash

Procedures

and

System Clock

can be found

on pages 15-17