Cable routing, Connecting the dyno electronics and shop air – Dynojet 224: Pit Installation Guide User Manual

Page 27

I N S T A L L A T I O N

Cable Routing

Version 4

In Ground Model 224 Automotive Dynamometer Installation Guide

2-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

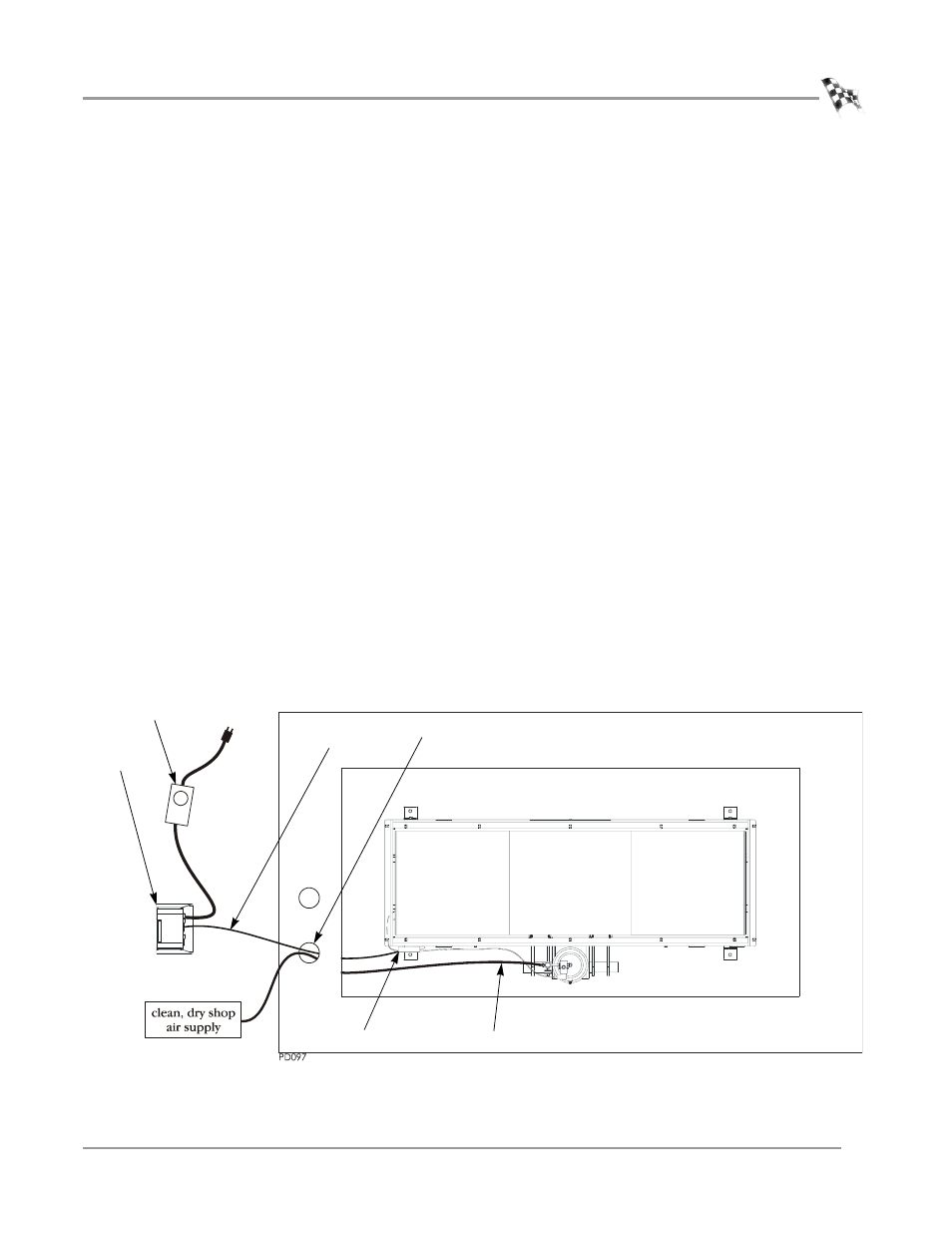

CABLE ROUTING

Use the following instructions to route the cables. You will need to route the cables

before installing the pit covers.

C

ONNECTING

THE

D

YNO

E

LECTRONICS

AND

S

HOP

A

IR

You will need the following parts:

• 318110301 Power Cord

• 42924250

25-pin Cable

• 53415040

Power Supply

• 76199003N Dyno Electronics

1

Route the 25-pin cable from the Breakout board, through one of the PVC conduits

in the pit, and to the dyno electronics.

Refer to page 1-10 for more information on connecting to the dyno electronics.

Refer to page 2-9 for more information on wiring the Breakout board.

2

Route the air hose from your shop air supply, through one of the PVC conduits in

the pit, and connect the air hose to the T fitting on the dyno brake solenoid.

Note: The air brake comes installed with a hose barb for a 3/8-inch inside

diameter air hose. If your hose does not have an inside diameter of 3/8-inch then

you will need an air hose nipple (1/4-inch NPT) to connect your clean, dry shop

air supply to the dyno. Once the pressure is connected, the air brake is ready to

use.

3

Connect the power supply to the dyno electronics. Plug the power supply into

your power source.

Figure 2-4: Route the Cables

power supply for

dyno electronics

breakout board

dyno

electronics

dyno electronics

cable

shop air

pit conduit