Motor specifications and electrical requirements – Craftsman 113.24181 User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

B.

Never use grinding wheels, abrasive cut-off wheels,

friction wheels (metal slitting blades) wire wheels or

buffing wheels.

11. USE ONLY ACCESSORIES DESIGNED FOR THIS

SAW.

12.

Cross-cutting operations are more conveniently worked

and with greater safety if an auxiliary wood facing is

attached to the miter gauge using the holes provided.

13.

Make sure the top of the arbor or cutting tool rotates

toward

you

when

standing

in

normal

operating

position. Also make sure the cutting tool, arbor collars

and arbor nut are installed properly. Keep the cutting

tool

as

low

as

possible

for

the

operation

being

performed. Keep all guards in place whenever possible.

14. Do not use any blade or other cutting tool marked for an

operating

speed

less

than

3450

RPM.

Never

use

a

cutting tool larger in diameter than the diameter for

which the saw was designed. For greatest safety and

efficiency

when

ripping,

use

the

maximum

diameter

blade for which the saw is designed, since under these

conditions the spreader is nearest the blade.

15.

Adjust table inserts flush with the table top. NEVER

operate the saw unless the proper insert is installed.

16. THINK SAFETY.

Safety is a combination of operator common sense and

alertness at alt times when the saw is being used.

17.

NOTE AND FOLLOW SAFETY INSTRUCTIONS

THAT APPEAR ON THE FRONT OF YOUR SAW.

DANGER

FOR YOUR OWN SAFETY

READ AND UNDERSTAND OWNER'S MANUAL

BEFORE OPERATING MACHINE;

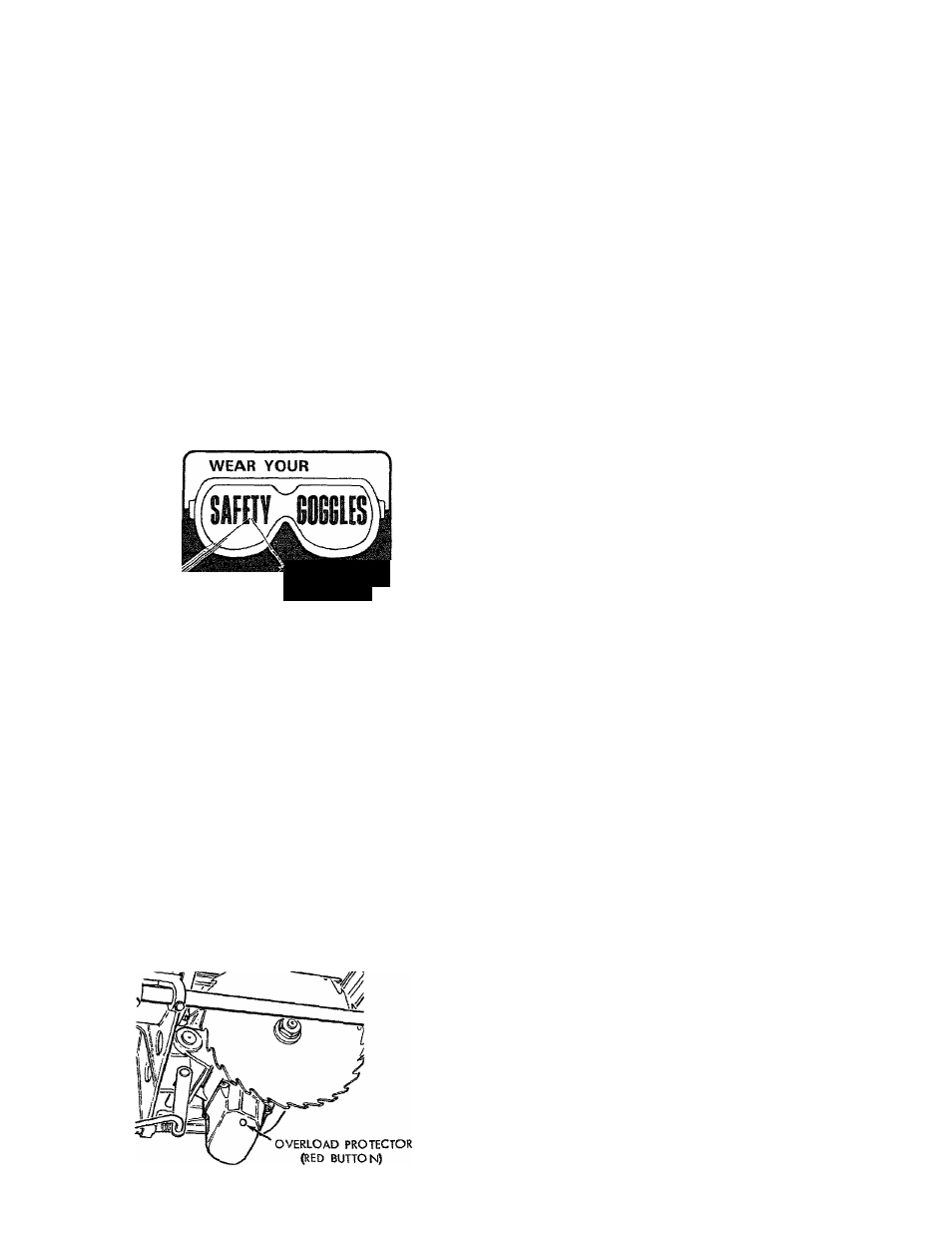

1. WEAR SAFETY GOGGLES

2. USE SAW-BLADE GUARD FOR "THRU-SAWING'

3. KEEP HANDS OUT OF PATH OF SAWBLADE

4. USE A "PUSH-STICK" WHEN REQUIRED

5. KNOW HOW TO AVOID "KICKBACKS"

6. DO NOT PERFORM OPERATIONS "FREEHAND"

18.

W A R N I N G : D O N O T A L L O W FAMILIARITY

(GAINED FROM FREQUENT USE OF YOUR SAW)

TO B E C O M E C O M M O N P L A C E . - A L W A Y S

REMEMBER THAT A CARELESS FRACTION OF A

SECOND IS SUFFICIENT TO INFLICT SEVERE

INJURY.

XFORESIGHT IS

'' BETTER THAN

N0 SIGHT

The

operation

of

any

power

tool

can

result

in

foreign

objects being thrown into the eyes, which can result in

severe eye damage. Always wear safety goggles complying

with

ANSI

Z87.1

(shown

on

Package)

before

commencing

power tool operation. Safety Goggles are available at Sears

retail or catalog stores.

MOTOR SPECIFICATIONS AND

ELECTRICAL REQUIREMENTS

MOTOR SPECIFICATIONS

The

AC

motor

used

in

this

saw

is

a

capacitor

start,

non-reversible type, with the following specifications:

Voltage................................................................................................240

Amperes ................................................................................................7

Hertz .....................................................................................................60

Phase ........................................................................................... Single

RPM .............................................................................................. 3450

Rotation (viewed from

sawblade end) ..................................................... Counterclockwise

MOTOR SAFETY PROTECTION

The

saw

motor

is

equipped

with

a

manual-reset

thermal

overload protector, designed to open the power line circuit

when the motor temperature exceeds a safe value.

1.

"If

motor

is

overloaded

and

overload

protector

is

actuated

(stopping

motor)

BE

POSITIVE

you

push

switch "OFF" immediately and allow the motor to coot

before

attempting

to

reset

the

protector.

Since

the

protector is near the sawblade, the switch must not be

turned "ON" until after you have reset the protector.

2.

If the red button will not snap into place immediately,

the motor is still too hot and must be allowed to cool

for a while longer.

3.

As soon as the red button will snap into running

position, the saw may be started and operated normally

by moving the saw switch lever to the "ON" position.

4.

Frequent opening of fuses or circuit breakers may result

if motor is overloaded, or if the motor circuit is fused

with a fuse other than those recommended. Do not use

a fuse of greater capacity without consulting the power

company.

5.

Although the motor is designed for operation on the

voltage

and

frequency

specified

on

motor

nameplate,

normal

loads

will

be

handled

safely

on

voltages

not

more than

10

% above or below the nameplate voltage.

Heavy

loads,

however,

require

that

voltage

at

motor

terminals

be

not

less

than

the

voltage

specified

on

nameplate,

6

.

Most

motor

troubles

may

be

traced

to

loose

or

incorrect

connections,

overloading,

reduced

input

voltage (which results when small size wires are used in