Adjustments, Miter gauge – Craftsman 113.24181 User Manual

Page 23

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ADJUSTMENTS

WARNING:

FOR

YOUR

OWN

SAFETY,

TURN

SWITCH

“OFF"

AND

REMOVE

PLUG

FROM

POWER

SOURCE

OUTLET BEFORE MAKING ANY ADJUSTMENTS.

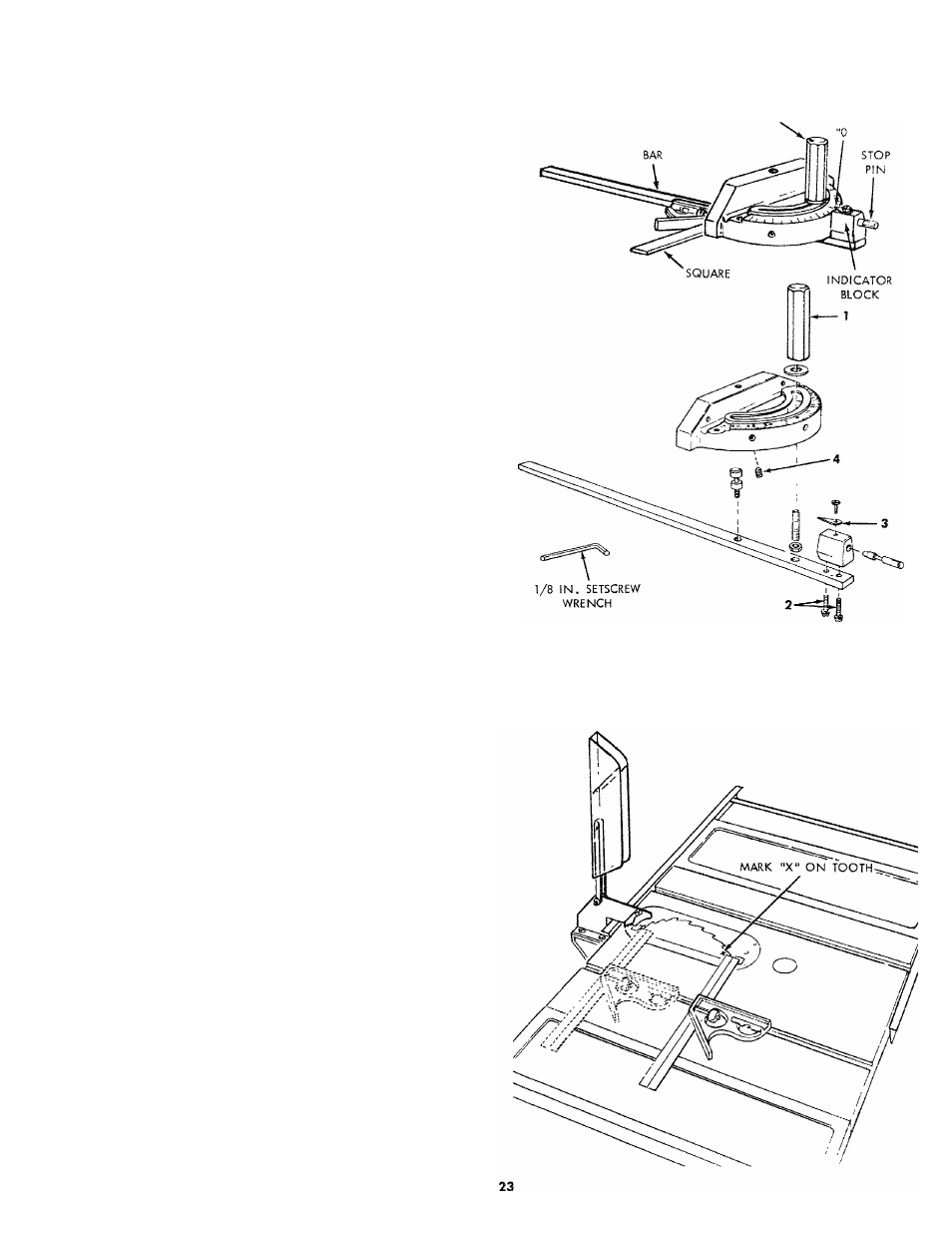

MITER GAUGE

NOTE: The holes for the stop pin and the graduations are

manufactured

to

very

close

tolerances

which

provide

accuracy

for

average

woodworking.

In some cases where

extreme accuracy is required, when making angle cuts, for

example, make a trial cut and then recheck it.

If necessary, the miter gauge head can be swiveled slightly

to compensate for any inaccuracy.

1.

Loosen the "handle" and pull "stop pin" OUT.

2.

Swivel the head . .. position it at "0" . .. push the

stop pin IN ... lock the handle.

3.

The HEAD should be square with the Bar and the

pointer

should

point

to

"0".

Readjust

the

pointer

if

necessary.

4.

If the head is not square with the bar, adjustments are

required.

A Loosen the "handle" (1) and the "two screws" (2)

B.

Position the HEAD square with the BAR using a

combination square.

C.

PUSH the STOP PIN into the hole in the head at

"

0

" . .. push the pin into the hole and twist it.

Lock the handle.

D.

Recheck with the square. If the head is still not

square,

loosen

the

screws

(

2

)

and

readjust

the

INDICATOR BLOCK.

E.

With the head square with the bar and the pin

pushed into the hole, adjust the pointer (3) to point

to "

0

".

F.

The miter gauge head must rest on top of the bar

without being able to move up and down .. . yet it

must swivel freely.

G. The swiveling movement of the head can be

LOCK HANDLE

adjusted by tightening or loosening the setscrew (4)

... using the

1/8

in. setscrew wrench.

NOTE: The setscrew is located inside of the head.

To reach it, swivel the head to 60 degrees and turn

the miter gauge upside down.

HEELING ADJUSTMENT or PARALLELISM

OF SAWBLADE TO MITER GAUGE GROOVE

While cutting, the material must move in a straight line

PARALLEL

to

the

SAWBLADE

..

.

therefore

both

the

miter

gauge

GROOVE

and

the

RIP

FENCE

must

be

PARALLEL to the SAWBLADE.

If the sawblade IS NOT parallel to the miter gauge groove,

the blade will bind at one end of the cut. {This is known as

"HEELING").

To check for parallelism:

WARNING

-

FOR

YOUR

OWN

SAFETY,

TURN

SWITCH

"OFF"

AND

REMOVE

PLUG

FROM

POWER

SOURCE

OUTLET.

1.

Raise blade all the way up.. . raise blade guard.

2.

Mark as "x" on one of the teeth which is SET (bent) to

the LEFT.

3.

Place

the

head

of

a

combination

square

in

the

GROOVE . .. adjust blade of square so that it just

touches the tip of of the MARKED tooth.

4.

Move square to REAR, rotate blade to see if MARKED

tooth again touches blade of square.

5.

If tooth touches square the same amount at FRONT

and

REAR

...

sawblade

is

PARALLEL

to

MITER

GAUGE GROOVE.