Craftsman 113.299780 User Manual

Page 17

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

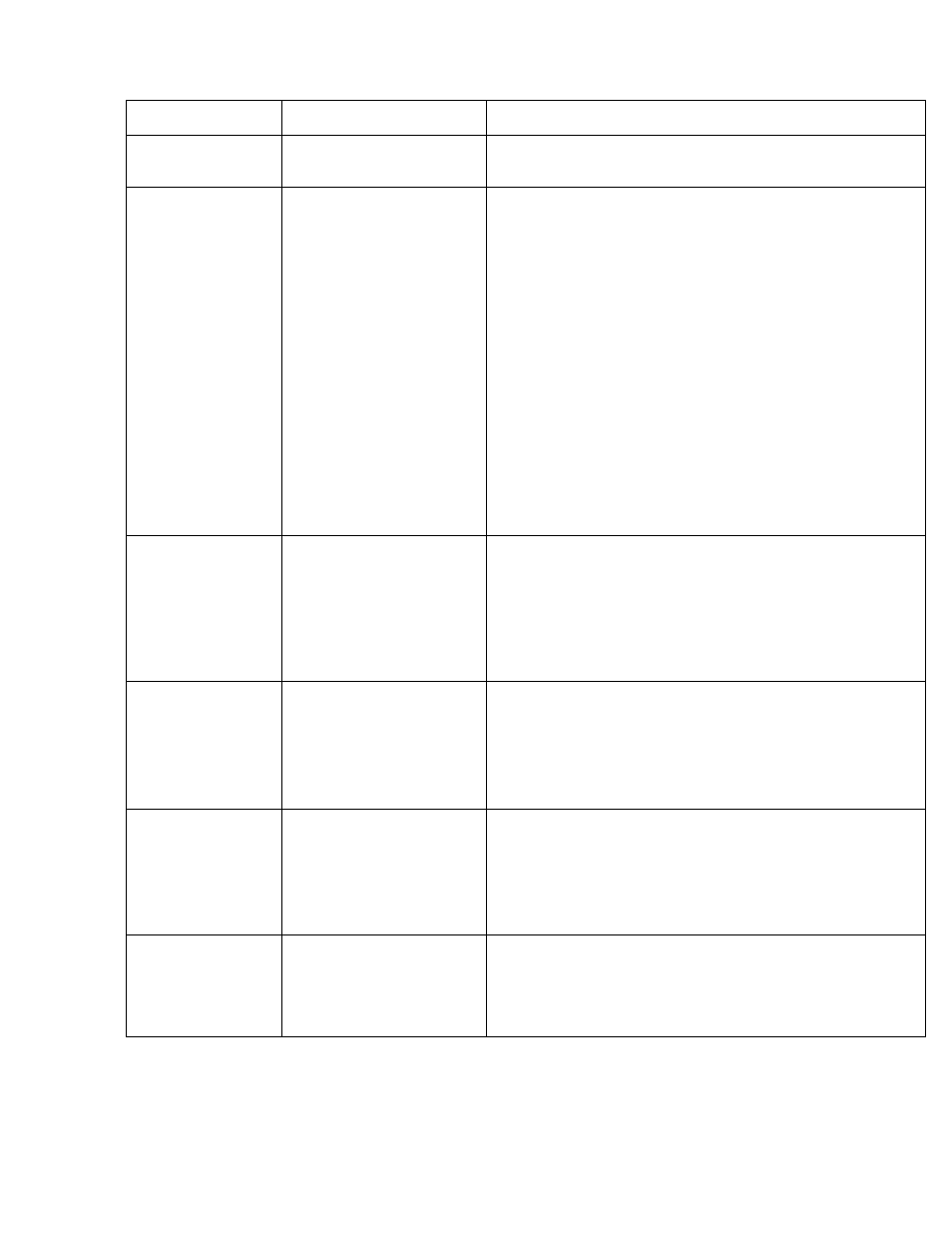

PROBLEM

PBOBABLE CAUSE

REMEDY SUGGESTED

Excessive noise.

1. M otor

1.

Have motorchecked by qualified

s^rvfce technician. R epair

service is avaiable at your nearest Sears store.

M otor fails to devel

op full pow er.

N O TE: LO W VO L

TAG E: (Pow er out

put of m otor de

creases rapidly w ith

decrease in voltage

at m otor term inals.

For exam ple, a

reduction of 10% in

voltage causes a

reduction of 19% in

m axim um pow er

output of w hich the

m otor is capable

and a reduction of

20% in voltage

causes a reduction

of 36% in m axim um

pow er output.)

1 - C ircuit overloaded w ith

lights, appliances and

other rm tors.

2. U ndersize extension cord

or extension cord too

long.

3. G eneral overloading of

pow er com pany facilities.

1. D o not use other appliances or m otors on sam e circuit

w hen using the Dust C ollection System .

2. Increase the wire sizes on extension cords, or reduce

length of extension cords. See "M otor Specifications and

Electrical R equirem ents" section.

3. R equest a pow er check from the pow er com pany.

M otor starts slow ly

or fails to com e up

to full speed.

1. Low voltage.

2. W indings burned out

or open.

3. Starting sw itch w ill not

operate. (Sw itch contacts

w orking properly.)

C apacitor is bad.

1. R equest voltage check from the power com pany.

2. H ave m otor repaired or replaced by a qualified service,

technician.

3. H ave capacitor replaced by a qualified service technician.

M otor overheats

1. M otor overloaded.

2. Im proper cooling. (Air

circulation restricted

through m otor due to

sawdust, accum ulating

inside of m otor.)

1. C lean out saw dust to provide norm al air circulation through

m otor. See "M aintenance" section.

M otor stalls

(resulting in blown

fuses or tripped

circuit breakers).

f. Voltage too low to perm it

m otor to reach operating

speed.

2. Fuses or circuit breakers

do not have sufficient

capacity.

1. R equest voltage check from the power com pany.

2. Install proper size fuses or circuit breakers.

Frequent opening of

fuses or circuit

breakers.

1. M otor overloaded.

2. Fuses or circuit breakers

dk> not have sufficient

capacity.

1 .Install proper size fuses or circxiit breakers.

NOTE; Motors used on wood-workir>g tools are particularly susceptible to the accorrajlation of saw

dust and wood chips and shouW be btown out or "vacuumed" frequently to prevent interference with

fKjrmal motor ventilation and proper operation of the centrifugally-operated starting switch.

17