Maintenance, M ain ten an c e, Motor – Craftsman 113.299780 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

maintenance

MOTOR

Excessive dust in m otor could cause excessive heaî in

m otor.

Every effort should be m ade to prevent foreign m aterial

from entering the m otor. W hen operated under condi

tions likely to perm it accum ulations of dust, dirt, or w aste

w ithin the m otor, a visual inspection should be m ade at

freguent intervals. Accum ulations of dry dust can usu

ally be blow n out successfully.

N O TE: M otors used O ft w ood-w orking tools are particu

larly

susceptible

toithe

accum ulation

of

saw dust

and

w ood chips and should be blown out or "vacuum ed"

frequently

to

prevent

interference

with

norm al

rnotor

ventilation.

To rem ove dust, blow off m otor w ith a low pressure air

^hose.:

-

___ CAUT50N; To avoid eye Injury or adverse

reaction to dust, high air pressure should not be

used especially In poorly ventilated areas.

The operator perform ing this cleaning function should

w ear safety goggles and filter m ask.

D o not use unit if power cord becom es worn or frayed.

If any servicing {other than the above cleaning) be

com es necessary, it should be perform ed by an author

ized Sears Service C enter.

N O TE: The speed of this m otor cannot be regulated or

changed.

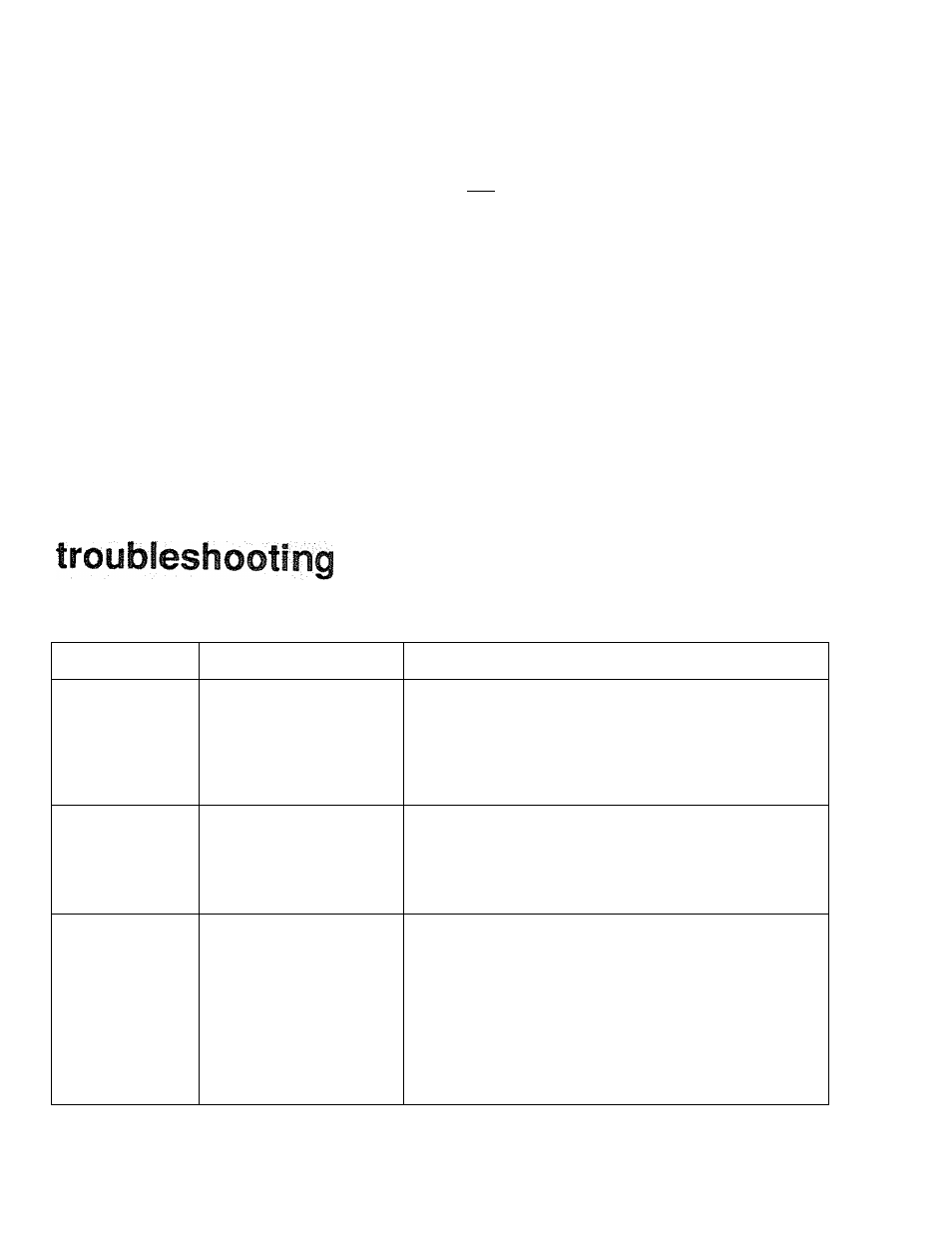

MOTOR

' i PROBLEM/)'),

PROBABLE CAUSE

REMEDY SUGGESTED

M otor vvilf not run.

1. D efective cord, plug,

sw itch and/or m otor.

2. Blown fuse.

1. C onsult Sears Service. Any attem pt to repair this m otor

m ay create a hazard unless repair is done by a qualified

service technician. Repair service is available at your

nearest Sears store.

2. C heck for blow n fuses and replace w ith fuse of proper

capacity.

Excessive

saw dust

in air.

1. Loose connectors

2. Filter/dust bag and/or

chip collection bag

releasing sawdust.

1 Tighten connections.

2. a. Saw dust trapped betw een clam p bag and housing,

b. Low er bag is hung up on saw dust shoot extension.

R eposition chip bag properly. See “M aintenance - C hip

Bag".

Excessive

im peller

noise.

1. Picked up large w ood

chips or debris.

2. Loose im peller.

3. R ubbing im peller.

1. D o not pick up m etal or ferrous m aterials. Stop the m achine

and the m aterial w ill.fall to the bottom of inlet tube.

2. U nplug unit prior to disassem bly. H azardous m oving

parts inside. Attach inlet guard before plugging in. Use

a piece of w ood to free im peller.

3. C onsult Sears Service to repair loose or rubbing im peller,

A repair to the housing m ay create a hazard unless it is

done by a qualified service technician. Repair service is

available at your nearest Sears store.

;i6