Table 4 - troubleshooting, Trouble possible cause possible remedy – Craftsman 196.205690 User Manual

Page 24

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

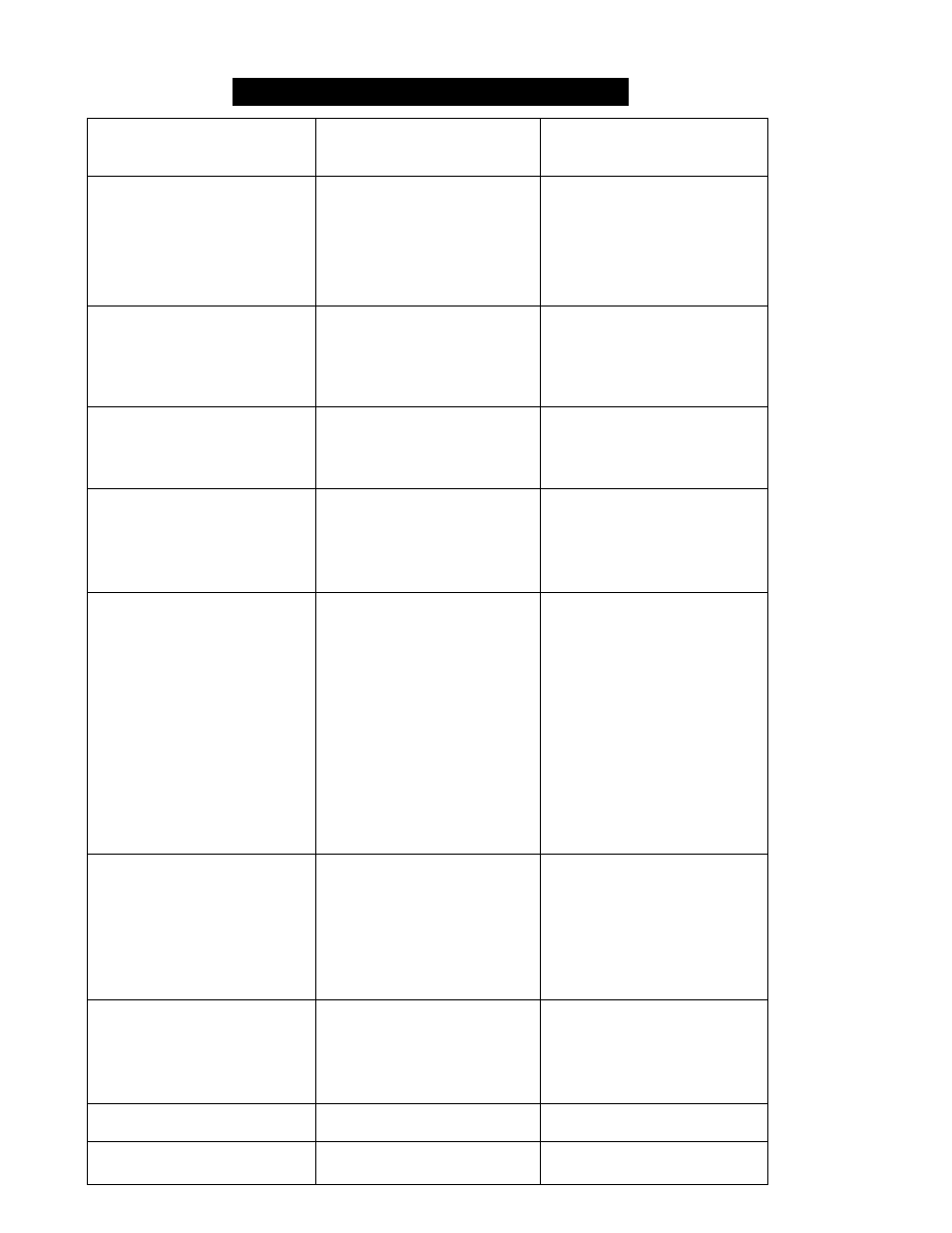

TABLE 4 - TROUBLESHOOTING

TROUBLE

POSSIBLE CAUSE

POSSIBLE REMEDY

Dirty, porous, brittle weld

1. Plugged welding nozzle

2. No shielding gas

3. Wrong type of gas

4. Dirty or rusty welding wire

1, Clean or replace nozzle.

2, Tank empty, flow restricted

or regulator set too low.

3. See SELECTING SHIELD

ING gas section of manual.

4. Replace spool of wire.

Wire feed works but no arc

1. Bad ground or loose

connection

2. Bad connection to gun or

faulty gun

1. Check ground and

connections. Tighten as

necessary.

2. Check connection to gun or

replace gun

Arc works but not feeding wire

1. Faulty wire speed control

assembly

2. No tension on drive roller

3. Faulty drive motor (RARE!)

1. Replace wire speed control

assembly.

2. Adjust the drive tension.

3. Replace drive motor.

Nothing works except fan

1. Faulty trigger on gun

2. Exceeded duty cycle;

thermal protector opened

3. Faulty transformer (RARE!)

1. Replace gun trigger.

2. Let welder cool at least

10 minutes (observe and

maintain proper duty cycle.)

3. Replace transformer.

Low output or non

penetrating weld

S ,

1. Loose connection inside

machine

2. Too long or improper

extension cord

3. Wrong type or size wire

4. Poor ground connection

5. Wrong size contact tip

6. Loose gun connection or

faulty gun assembly

7. Wrong welding polarity set

8. Dirty or rusty welding wire

1. Blow inside of machine out

with compressed air. Clean

and tighten all connections.

2. See EXTENSION CORDS

section of manual.

3. Use correct size wire.

4. Reposition clamp and check

cable to clamp connection.

5. Use correct size contact tip.

6. Tighten gun or replace gun.

7. Change to proper polarity.

8. Replace spool of wire.

Wire is jamming or

"birdnesting" at the

drive roller

1. Too much tension on

drive roller

2. Gun liner worn or damaged

3. Contact tip is clogged or

damaged

4. Liner stretched or is too tong

1. Adjust drive tension. (See

INSTALL THE

WELDING WIRE)

2. Replace gun liner.

3. Replace contact tip.

4. Trim liner to proper length.

Wire burns back to contact tip

1. Gun liner worn or damaged

2. Liner stretched or is too long

3. Wrong size contact tip

4. Contact tip is clogged or

damaged

1. Replace gun liner.

2. Trim liner to proper length.

3. Use correct size contact tip.

4. Replace contact tip.

Ground clamp and/or

ground cable gets hot

Bad connection from cable

to damp

Tighten connection or

replace cable.

Gun nozzle arcs to work

surface

Slag buildup inside nozzle

or nozzle is shorted

Clean or replace nozzle

as needed.

94