Step 2 — rig and mount the unit, Step 3 — complete refrigerant piping connections – Carrier 38AKS013-024 User Manual

Page 8

Step 2 — Rig and Mount the Unit

Be sure unit panels are securely in place prior to

rigging.

RIGGING — These units are designed for overhead rigging

only. For this purpose, the transverse base channels extend

beyond the sides of the unit, with holes provided in the end

plates to attach cables or hooks. Rig with top skid packaging

assembly in place to prevent unit damage by the rigging cable.

As further protection for the coil faces, plywood sheets can

be placed against the sides of the unit, behind the cables.

Run the cables to a central suspension point so that the angle

from the horizontal is not less than 45 degrees. Raise and set

the unit down carefully.

If it is necessary to roll the unit into position, mount

the unit on longitudinal rails, using a minimum of 3 rollers.

Apply force to the rails, not the unit. If the unit is to be skid-

ded into position, place it on a large pad and drag it by the

pad. Do not apply any force to the unit.

Raise from above to lift unit from the rails or pad when

unit is in final position.

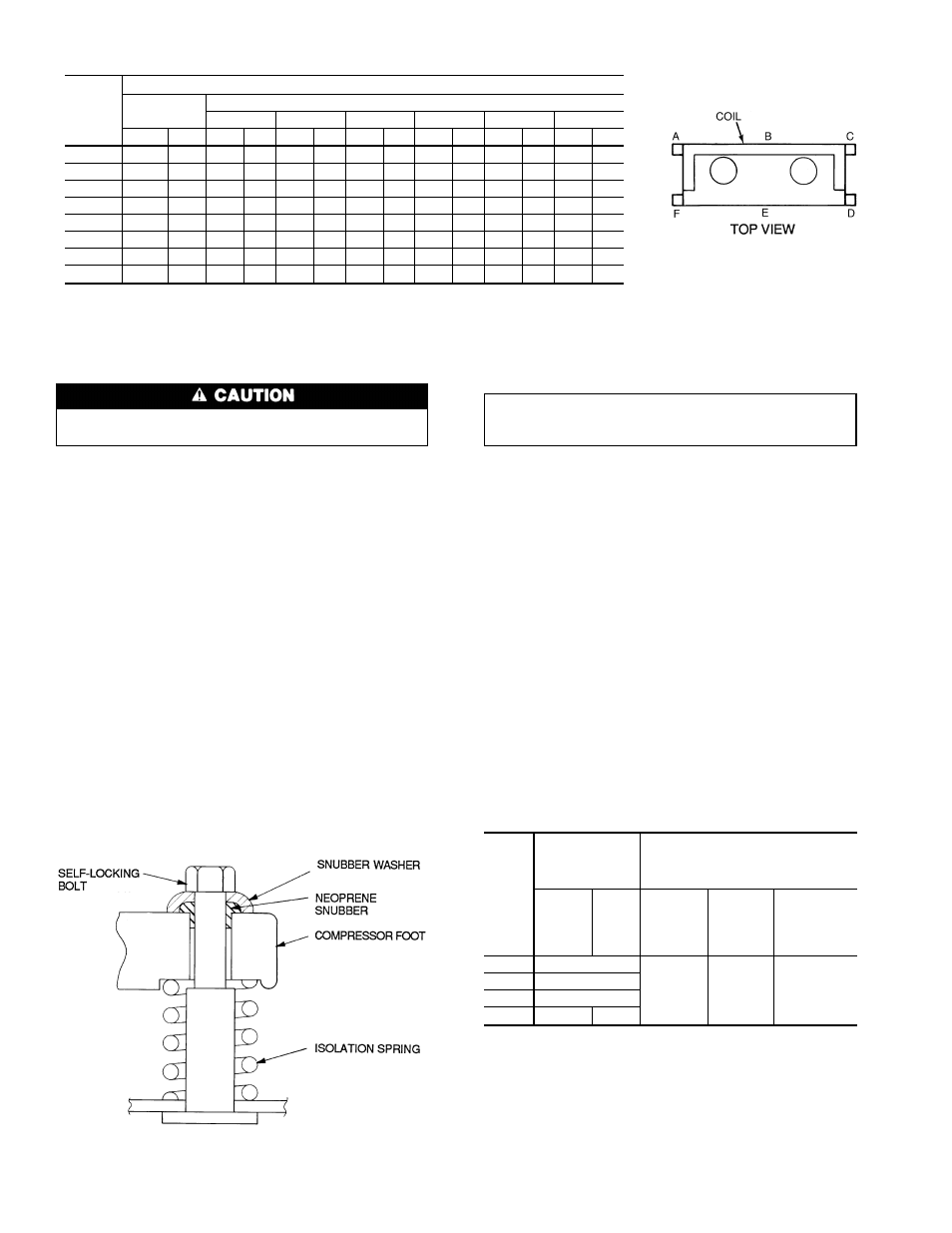

COMPRESSOR MOUNTING — As shipped, the compres-

sor is held tightly in place by self-locking bolts. Before start-

ing unit, loosen self-locking bolts until the snubber washer

can be moved sideways with finger pressure. Do not

remove shipping bolts. See Fig. 3.

Step

3

—

Complete

Refrigerant

Piping

Connections

IMPORTANT: A refrigerant receiver is not provided with

the unit. Do not install a receiver.

SIZE REFRIGERANT LINES — Consider the length of pip-

ing required between outdoor unit and indoor unit (evapo-

rator), the amount of liquid lift, and compressor oil return.

See Tables 3-5B and also refer to Part 3 of Carrier System

Design Manual and E20-II

software for design details and

line sizing. Refer to indoor unit installation instructions for

additional information.

NOTE: Use the piping data in Tables 3-5B as a general guide

only. For more precise calculations, refer to Carrier System

Design manual or E20-II software.

Condensing units with multiple-step unloading may

require double suction risers to assure proper oil return at

minimum load operating condition. See Tables 4A-5B and

Fig. 4. Reduction of evaporator coil surface should be ana-

lyzed to provide sufficient refrigerant velocity to return oil

to the compressor. Liquid line solenoid valves may be used

in certain situations to accomplish this. Hot gas bypass, if

used, should be introduced before the evaporator.

Note that refrigerant suction piping should be insulated.

Table 3 — Liquid Line Data

UNIT

38AKS

MAXIMUM

ALLOWABLE

LIQUID LIFT

ft (m)

LIQUID LINE

60 Hz

50 Hz

Maximum

Allowable

Pressure

Drop

psig (kPa)

Maximum

Allowable

Temp.

Loss

F (C)

Filter Drier

and

Sight Glass

Flare Conn.*

in. (mm)

013

52 (15.8)

7 (48.3)

2 (1.1)

5

⁄

8

(15.88)

014

67 (20.4)

016

82 (25.0

024

87 (26.5) 86 (26)

*Inlet and outlet.

NOTE: Data shown is for units operating at 45 F (7.2 C) saturated

suction and 95 F (35 C) entering air.

Table 2 — Weight Distribution

UNIT

38AKS

WEIGHT

Total

Operating

Support Point

A

B

C

D

E

F

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

lb

kg

013

732

332

94

43

93

42

93

42

149

68

151

68

152

69

013C

825

374

119

54

116

53

115

52

157

71

159

72

159

72

014

779

353

95

43

94

43

94

43

164

74

166

75

166

75

014C

919

417

131

59

129

59

128

58

176

80

177

80

178

81

016

789

358

95

43

95

43

96

44

167

76

168

76

168

76

016C

929

421

131

59

130

59

130

59

178

81

180

82

180

82

024

900

408

119

54

114

52

113

51

179

81

185

84

190

86

024C

1040

472

155

70

150

68

146

66

191

87

196

89

202

92

Fig. 3 — Compressor Mounting

8