Basic installation instructions, Indoor installation, Outside installation – Ames Fire & Waterworks 200B Bronze Double Check Valve Assemblies User Manual

Page 2: Parallel installation

First

Shutoff Valve

200BS

Strainer

2

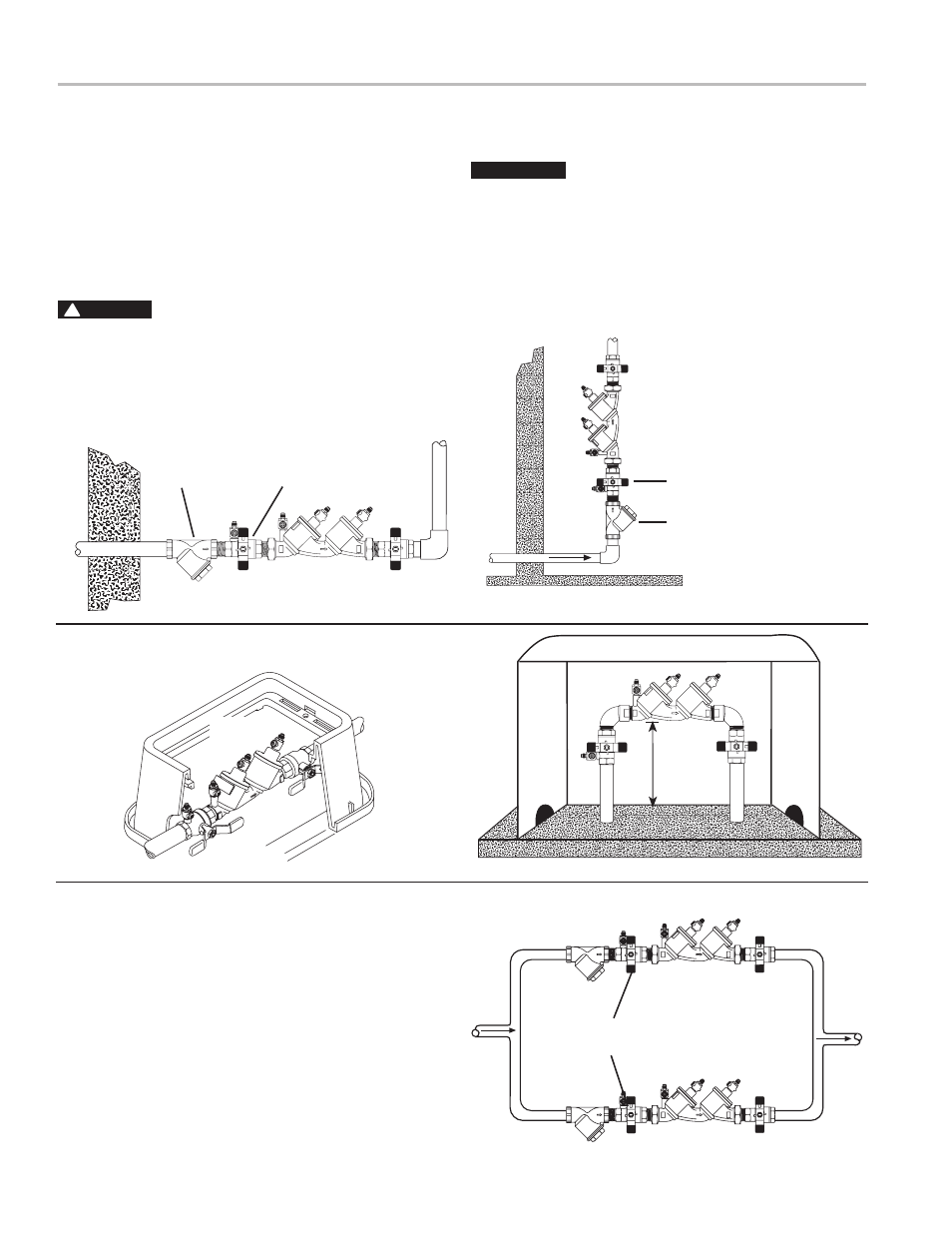

Indoor Installation

Ames Series 200B Double Check Valve Assemblies

Check local codes for installation requirements. Pipe lines

should be thoroughly flushed to remove foreign material before

installing the unit. A strainer should be installed as shown,

ahead of backflow preventer to prevent disc from unnecessary

fouling. Install valve in the line with arrow on valve body pointing

in the direction of flow.

For indoor installations, it is important that the valve be easily

accessible to facilitate testing and servicing. Do not install in a

concealed location.

CAUTION

!

Do not install with strainer when backflow preventer is used

on seldom used water lines which are called upon during

emergencies, such as fire sprinkler lines, etc.

It is important that series 200B be tested periodically in compliance

with local codes, but at least once a year or more often depending

upon system conditions. Regular inspection, testing and cleaning

assures maximum life and proper product function.

NOTICE

Fire Protection System Installations

The National Fire Protection Agency (NFPA) Guidelines require a

confirming flow test to be conducted whenever a “main line” valve

such as the shut off valves or a backflow assembly have been

operated. Certified testers of backflow assemblies must conduct

this test. The trim valves of the confirming flow test must be closed

during the test. When the test is completed the trim valves must be

returned to a fully open position.

Basic Installation Instructions

Outside Installation

Consult Local codes for Approval

Parallel Installation

Where approved by code, Ames recommends a custom

engineered Ames PVS series water supply valve station

consisting of two or more 200B series valves piped in parallel to

serve a larger supply main. This type of installation is employed

whenever it is required to maintain water flow to a facility. Typical

applications include hospitals, multi-family dwellings, malls and

other similar applications.

A properly designed Ames PVS valve station provides redundant

flow paths, a continuous supply of adequate water, testing and

servicing of an individual valve without supply interruption, and

long service life.

The size, quantities and design of parallel valve installations

should be exactly in accordance with the engineers judgment

and the published Best Practice Guide of Ames wherever

possible. For a copy of the Ames Best Practice Guide, call Ames

at 916-928-0123.

Meter Box

Installation

200BS

Min. 12"

200BA

First

Shutoff Valve

First Shutoff

Valve

200BS Vertical flow-up or vertical flow-down installation (flow-up shown)

Strainer

Ames

200B