Basic installation instructions, Guidelines, Relief valve discharge – Ames Fire & Waterworks LFM500, LFM500N, LFM500Z Lead Free Stainless Steel Reduced Pressure Detector Assemblies User Manual

Page 2

2

Guidelines

1. Most field problems occur because dirt and debris present

in the system at the time of installation becomes trapped

in the #1 check.

The system should be flushed before

the valve is installed. If the system is not flushed until after

the valve is installed, remove both check modules from the

valve and open the inlet shutoff to allow water to flow for a

sufficient time to flush debris from the water line. If debris in

the water system continues to cause fouling, a strainer can

be installed upstream of the backflow assembly.

2. The Series M400, M500, LFM500 may be installed in either

horizontal, “N” pattern, or “Z” pattern position as long as the

backflow assembly is installed in accordance with the direc-

tion of the flow arrow on the assembly and the local water

authority approves the installation.

3. The assembly should be installed with adequate clearance

around the valve to allow for inspection, testing and servic-

ing. 12" (300mm) should be the minimum clearance between

the lower portion of the assembly and the floor or grade. The

valve should be protected from freezing.

4. Installing a backflow preventer in a pit or vault is not

recommended.

5. Normal discharge and nuisance spitting are accommodated

by the use of an Ames air gap fitting and a fabricated indirect

waste line. Floor drains of the same size must be provided in

case of excessive discharge.

6. The M400, M500 and LFM500 backflow preventer should be

tested by a certified tester at the time of installation.

NOTICE

Assembly body should not be painted.

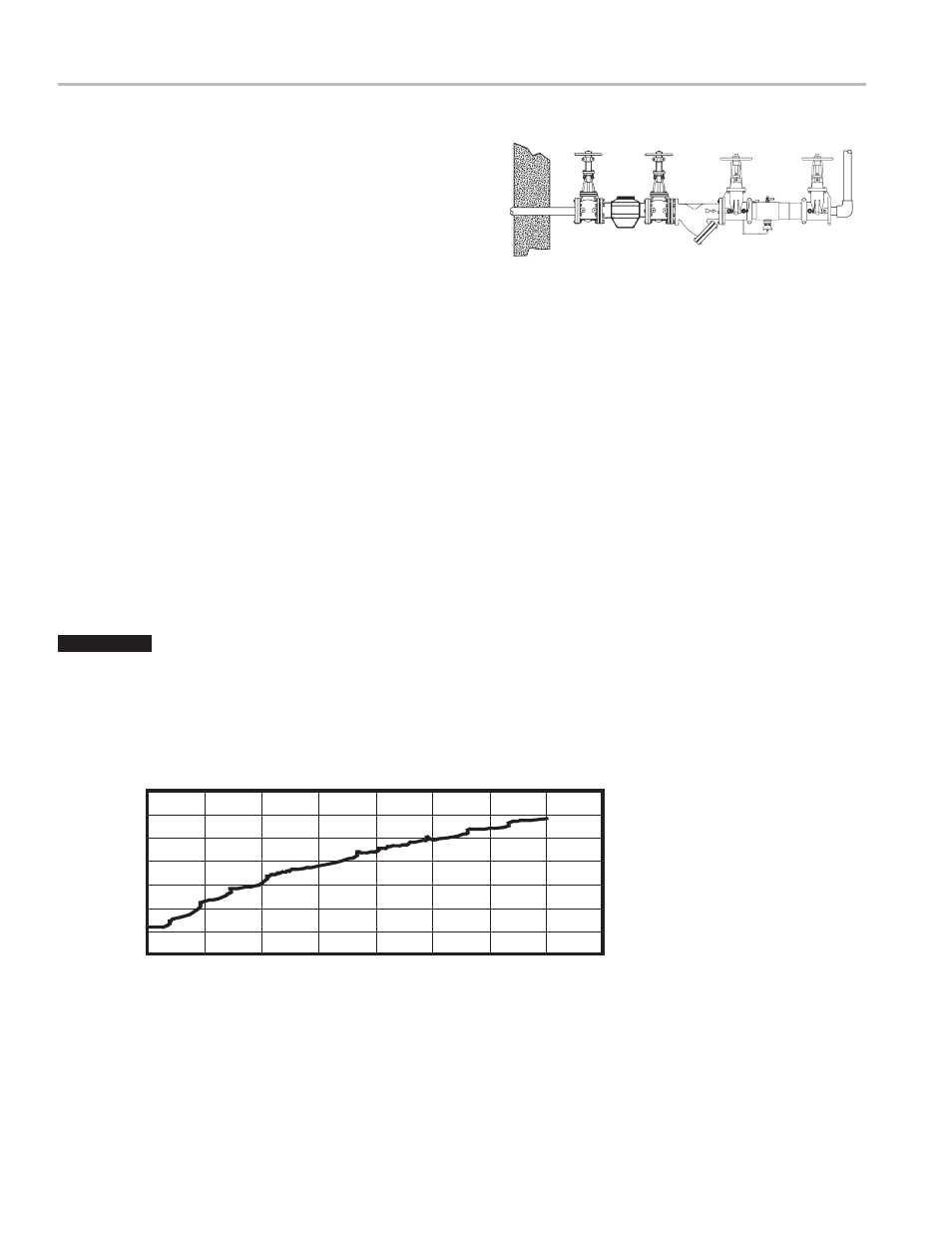

Horizontal Installation

Basic Installation Instructions

Relief Valve Discharge

2

1

/

2

" – 10" (65-250mm) Colt/Maxim 400 & 500, LF500

0 20 40 60 80

psi

0 138 276 414 552

kPa

lpm gpm

1330

350

1140

300

950 250

760 200

570 150

380 100

190

50

0 0

Rate of Flow

Pressure