Fig. 16 — locate units to prevent down-drafts 26 – Carrier MODULINE 37HS User Manual

Page 26

EVALUATE THE THROW OF MODULINE

UNITS IN

POSSIBLE LOCATIONS — Check minimum throw for

2-way blow diffuser near walls and all one-way blow

diffusers.

Exceeding maximum throw is almost never a problem. A

2-way blow unit covers 50 ft at nominal cfm.

In perimeter rooms, if 2-way blow units are off center,

favor the exterior wall if possible.

Generally, one-way blow diffusers should blow away from

the nearest wall.

Air throw data in Tables 4 and 5 for the Moduline

air

terminals provides the suggested minimum and maximum

coverages the units can handle in a typical installation while

maintaining the desired room conditions.

The optimum air throw values given in the table are dis-

tances from the unit centerline to the outside wall or nearest

obstruction (wall, light fixture, or opposing air stream).

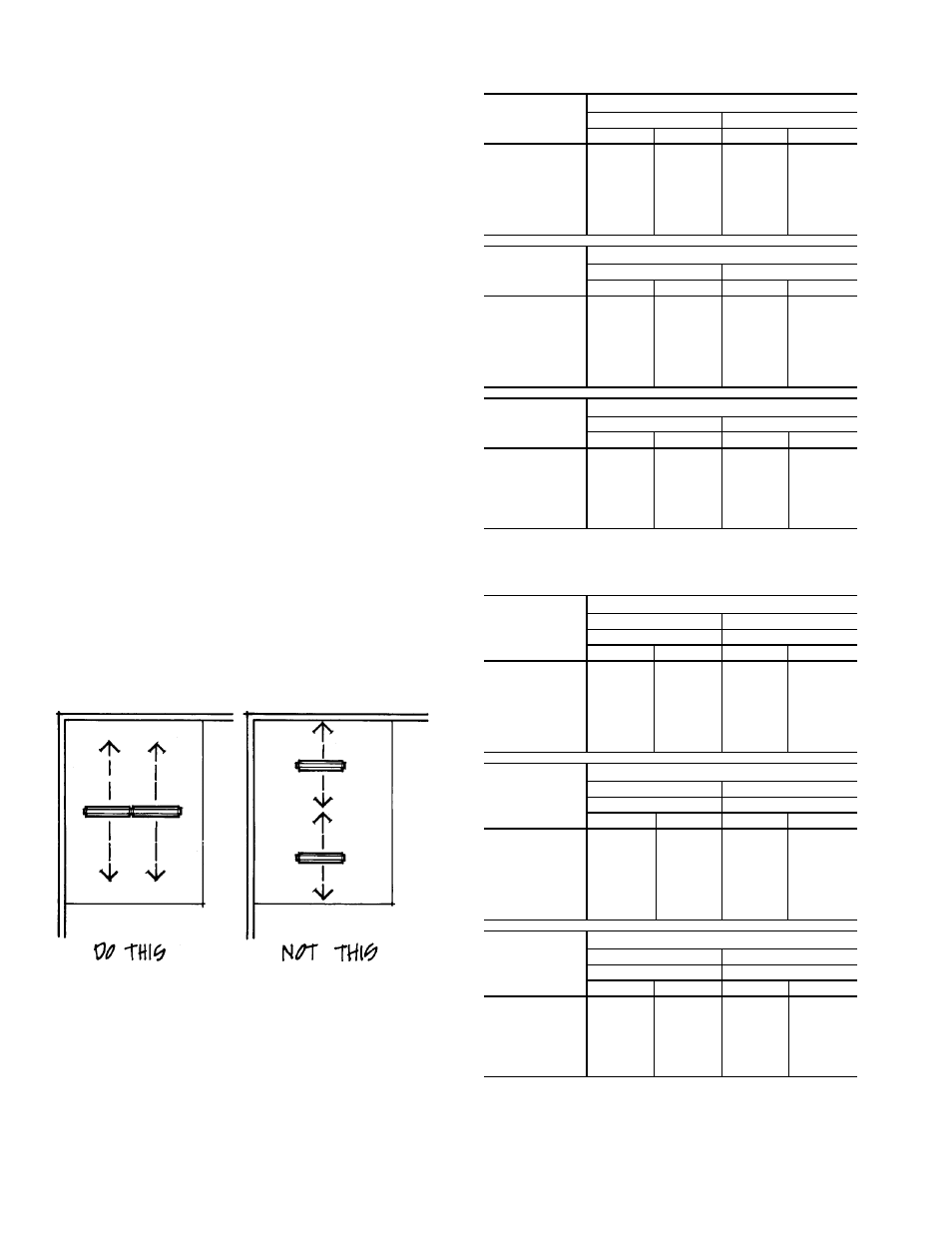

When given a choice, always put diffusers in line with each

other, not blowing at each other. If diffusers must be placed

so they are blowing at each other, the minimum throw must

be checked. Do not put units closer together than minimum

allows. Down-drafts caused by going below minimum will

bother room occupants. (Fig. 16)

Moduline

units can be placed fairly close to a wall or

partition. This is because the down-draft follows the wall

(stays close to the wall) and doesn’t bother the room occu-

pant. If furniture is placed against the wall near a Moduline

unit, it causes the air to be deflected causing drafts. The prob-

lem can often be solved by moving the furniture 6 in. or so

away from the wall.

Table 4 — Air Throw Data —

1-Way and 2-Way Blow, 2-Slot Diffusers

37HS1 UNIT

AIRFLOW

(Cfm)

OPTIMUM AIR THROW (ft)

1-Way Blow

2-Way Blow

Min

Max

Min

Max

40

2.0

7.0

2.0

5.0

50

4.0

9.0

3.0

6.0

60

7.5

12.0

3.5

7.5

70

8.0

15.0

4.0

9.0

80

9.0

18.0

4.5

10.5

90

10.0

20.0

5.0

11.5

100

11.0

22.0

6.0

13.0

110

12.0

24.0

7.0

15.0

37HS2 UNIT

AIRFLOW

(Cfm)

OPTIMUM AIR THROW (ft)

1-Way Blow

2-Way Blow

Min

Max

Min

Max

80

2.0

7.0

2.0

5.0

100

4.0

9.0

3.0

6.0

120

7.5

12.0

3.5

7.5

140

8.0

15.0

4.0

9.0

160

9.0

18.0

4.5

10.5

180

10.0

20.0

5.0

11.5

200

11.0

22.0

6.0

13.0

220

12.0

24.0

7.0

15.0

37HS4 UNIT

AIRFLOW

(Cfm)

OPTIMUM AIR THROW (ft)

1-Way Blow

2-Way Blow

Min

Max

Min

Max

160

8.5

16.0

5.0

7.0

200

10.0

20.0

6.0

10.0

250

11.0

21.0

7.0

13.0

300

12.0

22.0

8.0

17.0

350

14.0

23.0

9.0

19.0

400

15.0

25.0

10.0

21.0

440

17.0

29.0

13.0

24.0

Table 5 — Air Throw Data —

2-Way and 1-Way Director, 3-Slot Diffusers

37HS1 UNIT

AIRFLOW

(Cfm)

OPTIMUM AIR THROW (ft)

Heating

Cooling

1-Way Blow

2-Way Blow

Min

Max

Min

Max

40

2.0

7.0

2.0

5.0

50

4.0

9.0

3.0

6.0

60

7.5

12.0

3.5

7.5

70

8.0

15.0

4.0

9.0

80

9.0

18.0

4.5

10.5

90

10.0

20.0

5.0

11.5

100

11.0

22.0

6.0

13.0

110

12.0

24.0

7.0

15.0

37HS2 UNIT

AIRFLOW

(Cfm)

OPTIMUM AIR THROW (ft)

Heating

Cooling

1-Way Blow

2-Way Blow

Min

Max

Min

Max

80

2.0

7.0

2.0

5.0

100

4.0

9.0

3.0

6.0

120

7.5

12.0

3.5

7.5

140

8.0

15.0

4.0

9.0

160

9.0

18.0

4.5

10.5

180

10.0

20.0

5.0

11.5

200

11.0

22.0

6.0

13.0

220

12.0

24.0

7.0

15.0

37HS4 UNIT

AIRFLOW

(Cfm)

OPTIMUM AIR THROW (ft)

Heating

Cooling

1-Way Blow

2-Way Blow

Min

Max

Min

Max

160

8.5

16.0

5.0

7.0

200

10.0

20.0

6.0

10.0

250

11.0

21.0

7.0

13.0

300

12.0

22.0

8.0

17.0

350

14.0

23.0

9.0

19.0

400

15.0

25.0

10.0

21.0

440

17.0

29.0

13.0

24.0

NOTES:

1. Minimum air throw refers to the distance from the diffuser where the air ve-

locity is 150 fpm. In maximum air throw, this velocity has dropped to 50 rpm.

2. Data is based on an area with a 9-ft ceiling. For higher ceilings, values may

be reduced by one foot for each foot of height increase. For specific instal-

lations, minimum values can be reduced if properly qualified. Values are

dependent on cfm only and are not affected by duct pressure.

Fig. 16 — Locate Units to Prevent Down-Drafts

26