Insulation, Minimum fluid loop volume – Carrier EVERGREEN 23XRV User Manual

Page 23

23

Insulation

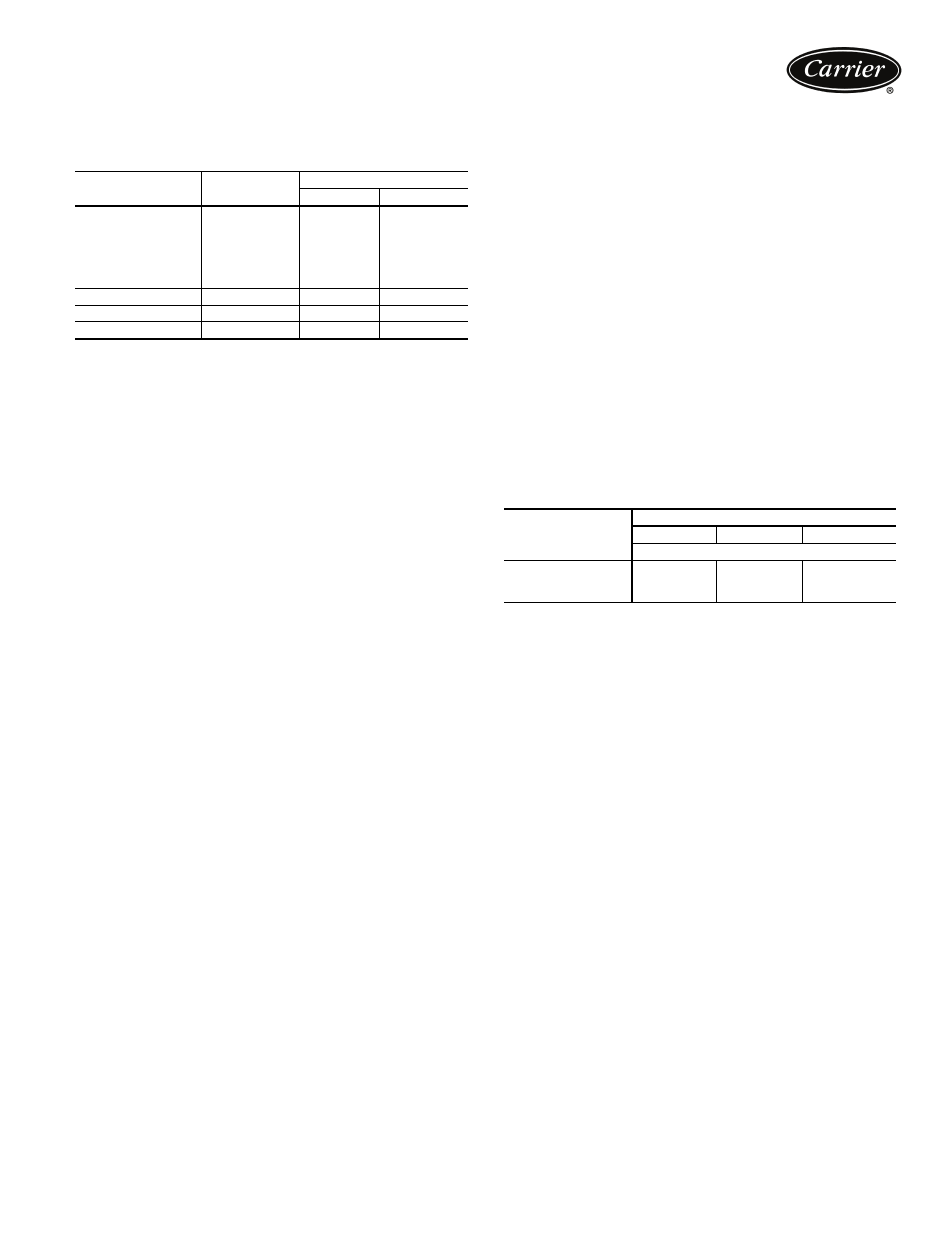

23XRV MINIMUM FIELD-INSTALLED INSULATION

REQUIREMENTS

Factory insulation — Thermal insulation is factory-

provided to the following areas:

• Cooler (not including waterbox)

• Suction line

• Compressor and motor

• Oil cooling line and oil return system line (oil and refrig-

erant lines at or near evaporator pressure are insulated)

• VFD cooling line (oil and refrigerant lines at or near

evaporator pressure are insulated)

• Motor cooling line

• Vaporizer

• Liquid line and discharge line

• Float chamber

• Optional economizer (including vent line and econo-

mizer muffler)

Factory insulation is not available for the waterboxes.

Insulation applied at the factory is

1

/

2

-in. (13 mm) thick

closed cell and

1

/

2

-in. (13 mm) open cell PVC-Nitrile foam.

Some parts of the chiller are also treated with an outer

layer of

3

/

16

-in. (5 mm) thick vinyl. The

1

/

2

-in. (13 mm)

closed cell foam has a thermal conductivity K value of

0.28 (BTU in.)/(hr sqft °F) [0.0404 W/(m °C)] and

conforms with Underwriters Laboratories (UL) Standard

94, Classification 94 HF-1. Both the

1

/

2

-in. foam and the

3

/

16

-in. vinyl layer will pass flammability test method

MVSS 302.

Field insulation — As indicated in the Condensation vs

Relative Humidity table, the factory insulation provides

excellent protection against condensation under most op-

erating conditions. If temperatures in the equipment area

exceed the maximum design conditions, extra insulation is

recommended.

If the machine is to be field insulated, obtain the approx-

imate areas from the 23XRV Minimum Field-Installed Insu-

lation Requirements table.

Insulation of waterbox is made only in the field and this

area is not included in 23XRV Minimum Field-Installed In-

sulation Requirements table. When insulating the covers,

allow for service access and removal of covers. To estimate

water-box cover areas, refer to certified drawings.

High humidity jobsite locations may require field sup-

plied and installed insulation on the float chamber, suction

housing, and the lower half of the condenser.

CONDENSATION VS RELATIVE HUMIDITY*

*These approximate figures are based on 35 F (1.7 C) saturated suction

temperature. A 2° F (1.1° C) change in saturated suction temperature

changes the relative humidity values by 1% in the same direction.

Minimum fluid loop volume

Minimum fluid volume must be in excess of 1.5 gal per ton

(20 L per kW) for comfort cooling applications and apply 3

to 5 gal per ton (40 to 66 L per kW) fluid loop volume for

process applications.

COMPONENT

SIZE

INSULATION

ft

2

m

2

Cooler

30-32

96

8.9

35-37

108

10.0

40-42

109

10.1

45-47

122

11.3

50-52

115

10.7

55-57

130

12.1

Misc. Liquid Lines

All Sizes

21

2.0

Economizer

All Sizes

20

1.9

Compressor Motor

All Sizes

17

1.6

AMOUNT OF

CONDENSATION

ROOM DRY-BULB TEMPERATURE

80 F (27 C)

90 F (32 C)

100 F (38 C)

% Relative Humidity

None

80

76

70

Slight

87

84

77

Extensive

94

91

84

910