Application data (cont), Vent and drain connections, Asme stamping – Carrier EVERGREEN 23XRV User Manual

Page 22: Relief valve discharge pipe sizing, Design pressures

22

Vent and drain connections

Nozzle-in-head waterboxes have vent and drain connec-

tions on covers. Marine waterboxes have vent and drain

connections on waterbox shells.

Provide high points of the chiller piping system with vents

and the low points with drains. If shutoff valves are provid-

ed in the main liquid pipes near the unit, a minimal amount

of system liquid is lost when the heat exchangers are

drained. This reduces the time required for drainage and

saves on the cost of re-treating the system liquid.

It is recommended that pressure gages be provided at

points of entering and leaving liquid to measure pressure

drop through the heat exchanger. Gages may be installed

as shown in Pressure Gage Location table. Pressure gages

installed at the vent and drain connections do not include

nozzle pressure losses.

Use a reliable differential pressure gage to measure pres-

sure differential when determining liquid flow. Regular gag-

es of the required pressure range do not have the accuracy

to provide accurate measurement of flow conditions.

PRESSURE GAGE LOCATION

ASME stamping

All 23XRV heat exchangers are constructed in accordance

with ASHRAE (American Society of Heating, Refrigerat-

ing, and Air Conditioning Engineers) 15 Safety Code for

Mechanical Refrigeration (latest edition). This code, in

turn, requires conformance with ASME (American Society

of Mechanical Engineers) Code for Unfired Pressure Ves-

sels wherever applicable.

Each heat exchanger and economizer (if equipped) is

ASME ‘U’ stamped on the refrigerant side of each vessel.

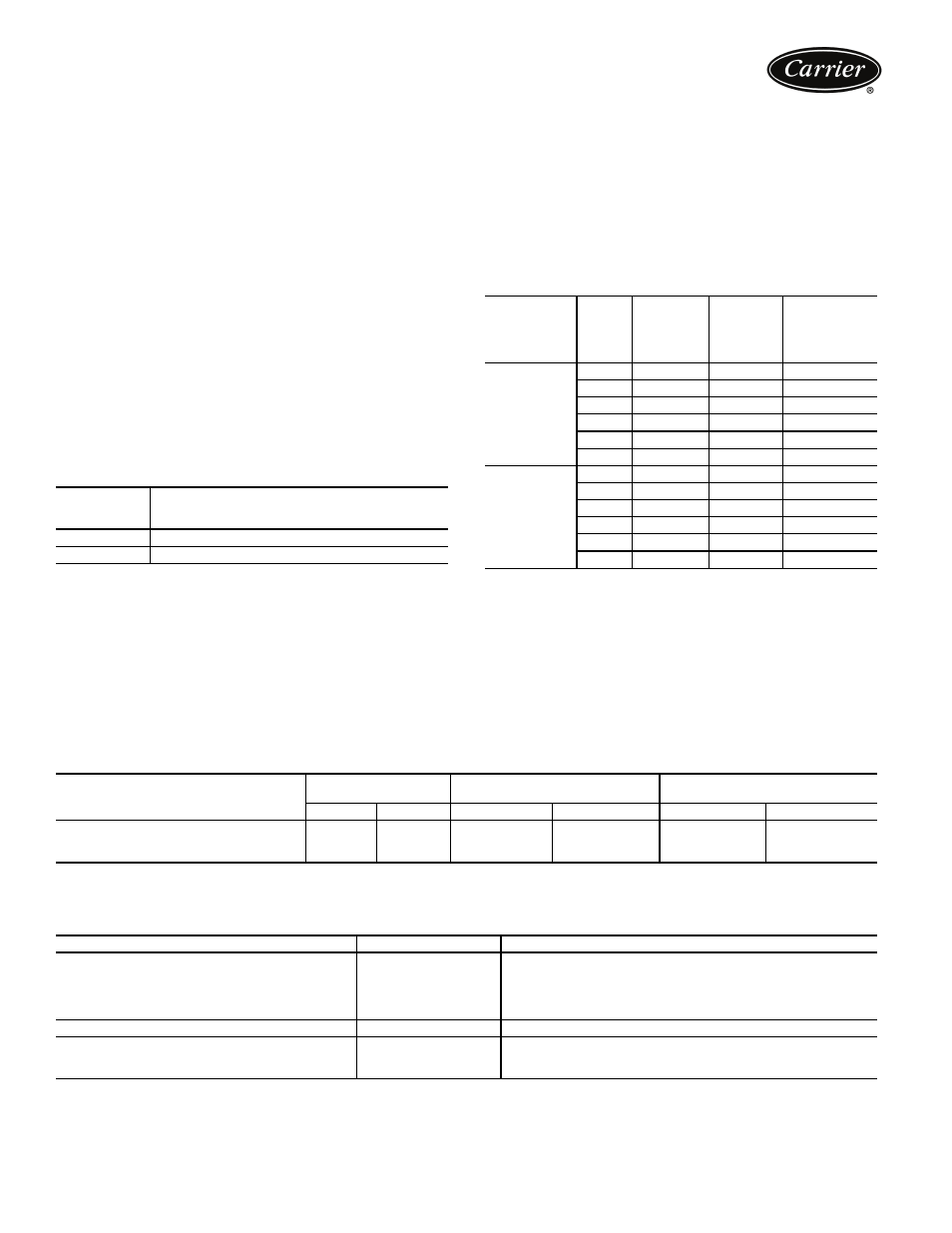

Relief valve discharge pipe sizing

See page 21 for number of relief valves.

Relief valve discharge piping size should be calculated

per the current version of the ASHRAE 15, latest edition,

code using the tabulated C factors for each vessel shown in

the table below.

23XRV RELIEF VALVE DISCHARGE PIPE SIZING

Carrier further recommends that an oxygen sensor be

installed to protect personnel. Sensor should be able to

sense the depletion or displacement of oxygen in the ma-

chine room below 19.5% volume oxygen per ASHRAE

15, latest edition.

Design pressures

Design and test pressures for heat exchangers are listed

below.

DESIGN AND TEST PRESSURES (23XRV)

*Nitrogen/Helium.

HEAT EXCHANGER MATERIAL SPECIFICATIONS

LEGEND

NUMBER

OF

PASSES

GAGE LOCATION

(Cooler or Condenser)

1 or 3

One gage in each waterbox

2

Two gages in waterbox with nozzles

HEAT

EXCHANGER

FRAME

SIZE

VESSEL

REQUIRED

C FACTOR

(lb air/Min)

RELIEF

VALVE

RATED

C FACTOR

(lb air/Min)

FIELD

CONNECTION

SIZE (FPT)

COOLER

30 to 32

43.4

70.8

1

1

/

4

35 to 37

49.5

70.8

1

1

/

4

40 to 42

50.4

70.8

1

1

/

4

45 to 47

57.4

70.8

1

1

/

4

50 to 52

53.7

70.8

1

1

/

4

55 to 57

61.1

70.8

1

1

/

4

CONDENSER

30 to 32

41.4

70.8

1

1

/

4

35 to 37

47.1

70.8

1

1

/

4

40 to 42

47.1

70.8

1

1

/

4

45 to 47

53.7

70.8

1

1

/

4

50 to 52

51.2

70.8

1

1

/

4

55 to 57

58.3

70.8

1

1

/

4

PRESSURES

SHELL SIDE

(Refrigerant)

STANDARD TUBE SIDE

(Liquid)

OPTIONAL TUBE SIDE

(Liquid)

psig

kPa

psig

kPa

psig

kPa

Leak Test at Design Pressure*

185

1276

150

1034

300

2068

Hydrostatic

—

—

195

1344

390

2689

Proof Test*

204

1407

—

—

—

—

ITEM

MATERIAL

SPECIFICATION

Shell

HR Steel

ASME SA516 GR 70

Tube Sheet

HR Steel

ASME SA516 GR 70

Condenser/Cooler Waterbox Cover

HR Steel

ASME SA516 GR 70, SA-36, or SA-285 GRC

Condenser/Cooler Waterbox Shell

HR Steel

ASME SA675 GR 60, SA-516 GR70, or SA-181 CL70,

SA-36, SA-675 GR70, SAE AME 7496

Tubes

Finned Copper

ASME SB359

Discharge/Suction

Pipe

Steel

ASME SA106 GRB

Flanges

Steel

ASME SA105

ASME — American Society of Mechanical Engineers

HR

— Hot Rolled

Application data (cont)