Tube error codes – Drucker Diagnostics QBC STAR Dry Hematology Analyzer User Manual

Page 66

QBC Star System Operator’s Manual

6000-300-000 7–16

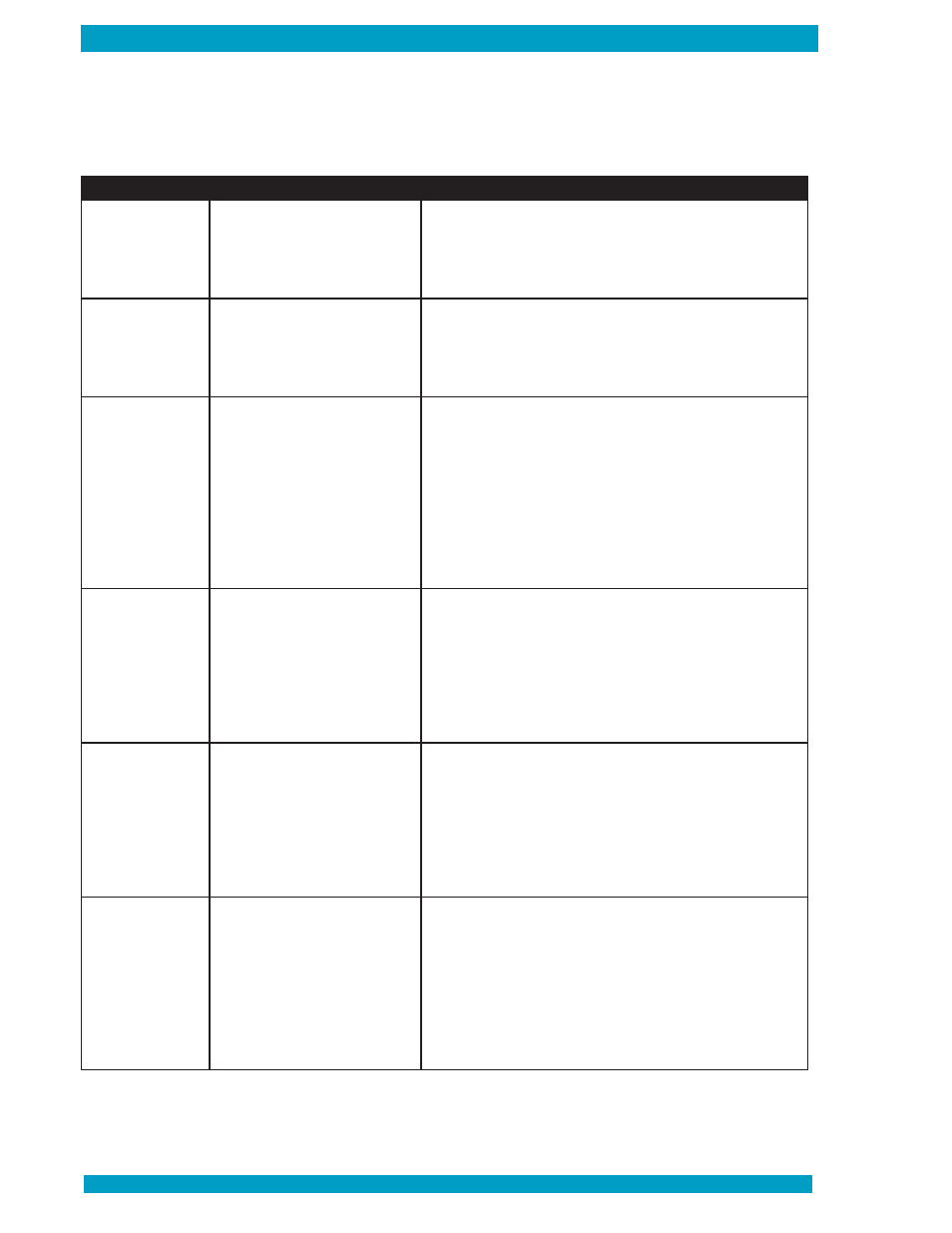

Error Number

Description

Corrective Action

1

Low fill volume

1. Record the error message on the LCD display

2. Create a support file (Ref. page 2-8)

3. Prepare a new tube (Ref. pages 4-2 through 4-5)

4. Insert the tube into the instrument, close the door and press

the “STAR” button

2

High fill volume

1. Record the error message on the LCD display

2. Create a support file (Ref. page 2-8)

3. Prepare a new tube (Ref. pages 4-2 through 4-5)

4. Insert the tube into the instrument, close the door and press

the “STAR” button

3

Bad float length

1. Record the error message on the LCD display

2. Create a support file (Ref. page 2-8)

3. If the lid is not open, depress the door release latch located

on the front of the instrument.

4. Rotate the tube 180 degrees and reinsert it in the rotor

5. Close the lid and rerun the tube (Ref. page 4-7)

6. If the problem persists, prepare a new tube, insert it into the

instrument, close the lid and press the “STAR” button

7. If the problem persists after rerunning a new tube, create a

new support file and contact Technical Support

4

Bad float signature

1. Record the error message on the LCD display

2. Create a support file (Ref. page 2-8)

3. Open the lid, rotate the sample 180 degrees and reinsert it

into the rotor

4. Close the lid and rescan the sample

5. If the problem persists, draw a new sample and retest

6. If the problem persists after rerunning a new tube, create a

new support file and contact Technical Support

6

Unreadable buffy coat

1. Record the error message on the LCD display

2. Create a support file (Ref. page 2-8)

3. Open the lid, rotate the sample 180 degrees and reinsert it

into rotor

4. Close lid and rescan the sample

5. If the problem persists, draw a new sample and retest

6. If the problem persists after retest, create a new support file

and contact Technical Support

7

Float not descended

1. Record the error message on the LCD display

2. Create a support file (Ref. page 2-8)

3. Open the lid and visually check the sample

a. If the float did not descend or no visible buffy layer is

observed, draw a new sample and retest

b. If the float is descended or a visible buffy layer is observed,

rotate the sample 180 degrees and rescan the sample

4. If the problem persists, create a new support file and contact

Technical Support

If any of the following tube error messages appear on the printer results report and LCD display, fill and

run a new tube.

Tube Error Codes