User responsibility – Amico Nema 4 Master Alarm User Manual

Page 18

18

Amico Pipeline

SETTING FACTORY DEFAULT

To quickly reset the module (Pressure or Vacuum) to the factory default settings as follows:

- Pressure: High set-point 60 Psi, Low set-point 40 Psi.

- Nitrogen & HP Air: High set-point 195 Psi, Low set-point 140 Psi.

- Vacuum: Low set-point 12 inchHg.

- No Repeat alarm, but set for 30 min..

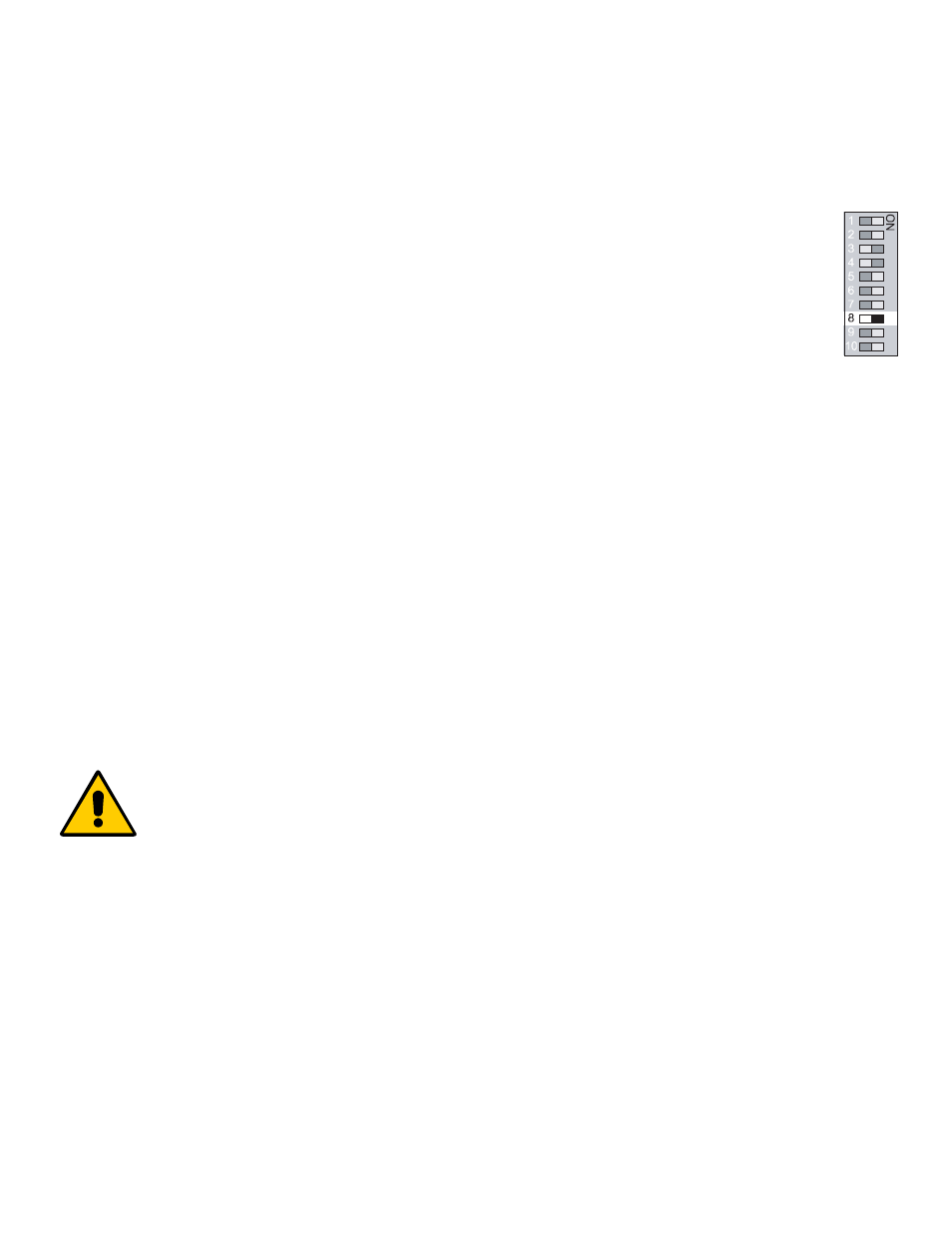

1. Set switch #8 to the ON position.

2.

Turn the power off (wait 5 seconds) then back on.

3.

Set switch #8 to the OFF position.

The module is now in the default mode.

A m i c o M i c r o p r o c e s s o r B a s e d A l a r m

P a g e : 4

USER RESPONSIBILITY

The information contained in this Installation and Operation Maintenance

Manual, pertains only to the ALERT-2 microprocessor based digital alarm.

This product will perform to conformity with the descriptions contained in this

manual, when assembled, operated, maintained and serviced in accordance

with the installation instructions provided.

The alarm must be checked periodically. Parts that are broken, missing,

worn, distorted or contaminated, must be replaced immediately. Should such

repair or replacement become necessary, please contact Amico Corporation

or their distributors.

All alarms should not be repaired, or altered without prior written or verbal

approval of Amico Corporation or it’s distributors. Failure to comply will void

all warranty on the alarm.

Statements in this manual preceded by the words

WARNING

,

CAUTION

,

DANGER and

NOTE

are of special significance. Please read these sections

carefully.

WARNING:

denotes steps which can prevent injury.

CAUTION:

denotes steps which can prevent damage to equipment.

DANGER:

denotes steps which can prevent electrical shock to equipment

or to prevent serious injury and/or death.

SETTING GAS IDENTIFICATION SWITCHES

PLEASE NOTE: DO NOT tamper with switches #1, #2 and #3 on the dip-switch. Tampering with these positions will

result in an error message being displayed (EO2) and will disable the electrical interlock from the gas specific sensor.

Changes to these switches should only be done by properly trained personnel, when circuit

boards have to be changed in the field.

Switches # 1, #2 and #3 are used for the gas identification of the display module. These will be set at the factory and

should not be tampered with in the field.