Opener-frame clearance, Marker maintenance, Marker transport carrier – Great Plains 3S-3000HDF Operator Manual v2 User Manual

Page 84: Marker shear bolt, Marker transport carrier marker shear bolt

80

3S-3000HD

Great Plains Manufacturing, Inc.

195-068M

2014-02-11

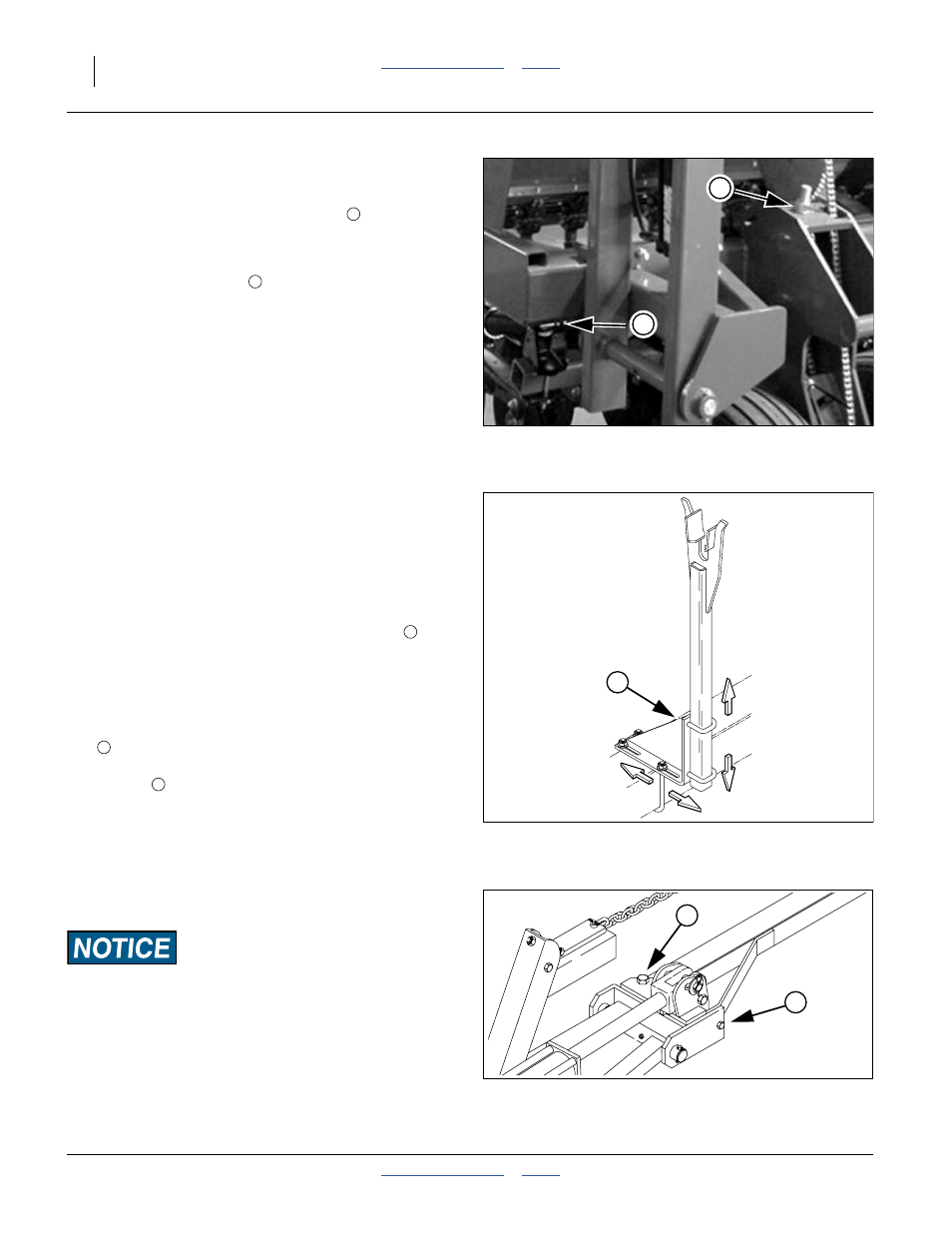

Opener-Frame Clearance

Refer to Figure 88

When fully raised, top of opener mounts

should clear

bottom of drill frame tube by at least

1

⁄

2

inch (12.7mm).

To adjust opener frames so all openers have the same

clearance, loosen jam nut

on opener lift cylinders and

turn adjustment nut. When openers are at the correct

height, retighten jam nut. Repeat at each opener lift

cylinder if necessary.

Marker Maintenance

Marker Transport Carrier

When marker is folded, the second section should be

centered in transport carrier saddle and be parallel with

top of drill box.

Refer to Figure 89

To adjust height of saddle, loosen

1

⁄

2

x2in U-bolts

that

hold carrier tube to mounting bracket. Slide carrier tube

up or down as needed.

Marker Shear Bolt

The marker arm is attached to marker body with a shear

bolt

, which is intended to fail if the marker strikes an

obstruction, allowing the marker to swing back around a

second bolt

.

If the shear bolt breaks, replace it with an equivalent

3

⁄

18

-16x2in Grade 2 bolt (Great Plains part 802-266C). If

that size is not available in your local market, temporarily

substitute an M10x1.5 Class 5.8 metric bolt and nut.

Note: Replacing the bolt with a lower grade, or smaller

size, can result in nuisance shears.

Equipment Damage Risk:

Replacing the bolt with a higher grade can result in marker

damage.

FigureSpacer

Figure 88

Opener Frame Clearance

18853

2

1

1

2

FigureSpacer

Figure 89

Marker Transport Carrier

15632

1

1

2

3

FigureSpacer

Figure 90

Marker Shear Bolt

15669

2

3