Marker setup, Re h s – Great Plains 3S-3000HDF Operator Manual v2 User Manual

Page 110

106

3S-3000HD

Great Plains Manufacturing, Inc.

195-068M

2014-02-11

Marker Setup

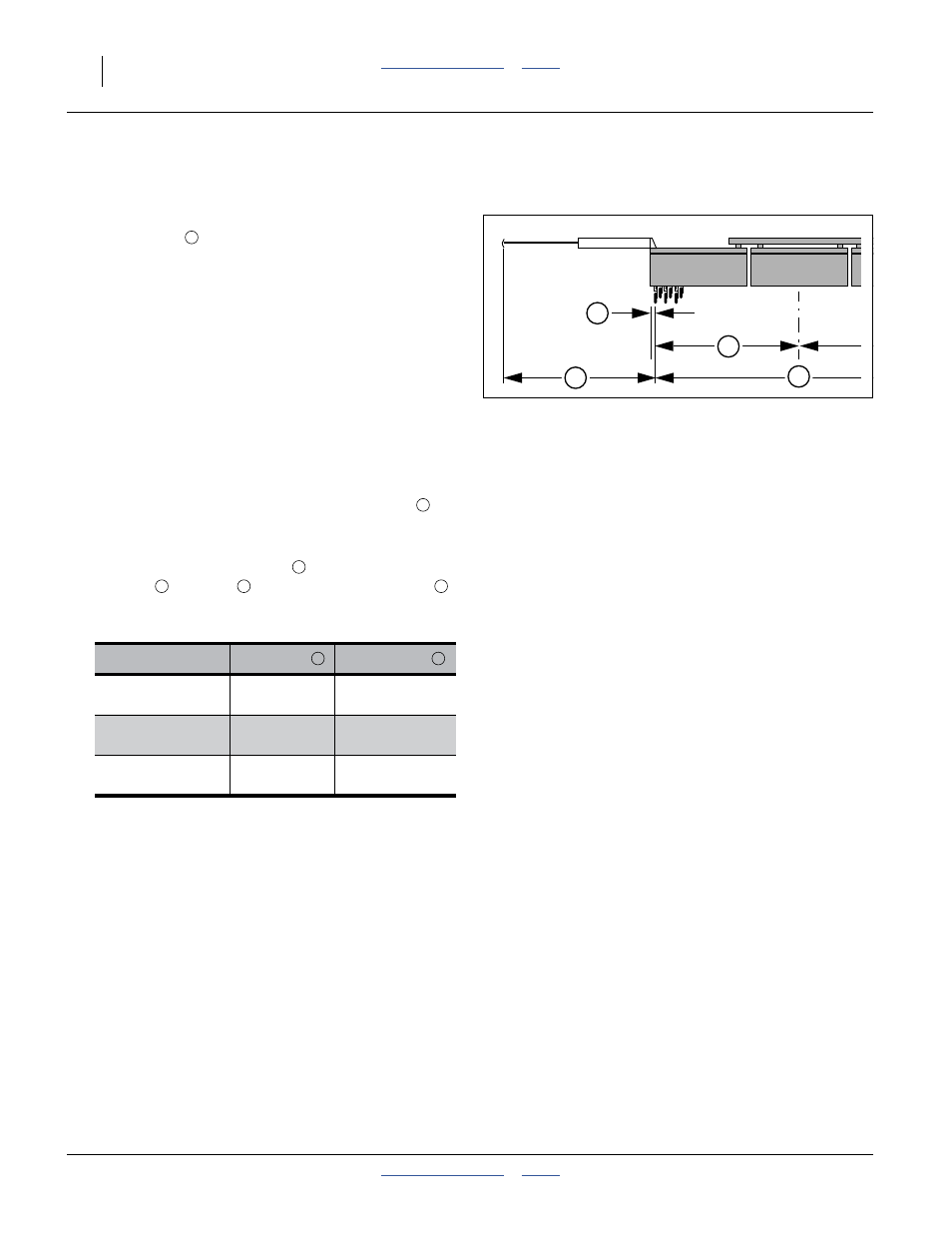

Refer to Figure 95

Markers are field-installed, but usually do not have their

extension length

precisely set. The drill must be

leveled per “Center Box Frame Leveling” on page 74,

and marker(s) must be in correct working order per

“Marker Maintenance” on page 80.

Row unit centerline stations on 3S-3000HD drills are

symmetrical about machine center, so left and right

extensions are normally identical, for both opposing and

concentric passes.

Set the initial length of the marker(s) as follows:

1.

Lower drill and openers to field position (“Raising

and Lowering Openers” on page 23).

2.

Extend a marker on one side. Pull forward several

feet to leave a mark.

3.

Sighting parallel to the main tool bar, measure

from the centerline of the left outside row unit to the

mark.

4.

Adjust the marker extension

so that the mark is

one half

the span

plus one row unit spacing

.

See “Marker Adjustments” on page 59 for setting

marker extension.

5.

Pull forward several feet, and re-measure to verify

any adjustment. Validate the mark by making a pass

to one or both sides.

6.

Fold marker. Extend other side and adjust.

Note: If field conditions require inverting the marker disk

(page 61), the mark moves, and the extension

needs to be re-measured and reset. Marking also

changes slightly if the opener frame trunnion posi-

tion is changed (page 53).

End of Appendix B - Initial Setup

Model

Spacing

Extension

3S-3000HD-3610

10 in

185.0in

(469.9cm)

3S-3000HD-4875

7.5 in

184.75in

(469.3cm)

3S-3000HD-6006

6 in

185.5in

471.2cm

R

E

H

S

FigureSpacer

Figure 95

Marker Extension

E

E

E

H

S

R

R

E