Marker adjustments, Marker width – Great Plains 3S-3000HDF Operator Manual v2 User Manual

Page 63

Great Plains Manufacturing, Inc.

Adjustments

59

2014-02-11

195-068M

Marker Adjustments

Pinch, Crush and Sharp Object Hazards:

You may be injured if hit by a folding or unfolding marker.

Markers may fall quickly and unexpectedly if the hydraulics

fail. Never allow anyone near the drill when folding or unfold-

ing the markers.

There are four operating adjustments for markers:

• Marker Width

Once set for a specific row spacing, this only needs

periodic checking to ensure the clamp is secure.

• Disk Angle

Even if your row spacing rarely changes, you may

need to adjust disk angle for soil conditions and plant-

ing speed.

• Chain Length

You may want to adjust the chain length to ensure the

markers track uneven ground, and do not drag exces-

sively when markers are folded.

• Marker Speed

Once initially set by your dealer, this rarely needs

modification.

There are also three maintenance items for markers:

• “Bleeding Marker Hydraulics” on page 73

• “Marker Shear Bolt” on page 80

Marker Width

Marker extension depends on drill size, row unit spacing

and row units in use.

See “Marker Setup” on page 106 for initial values for

marker extension.

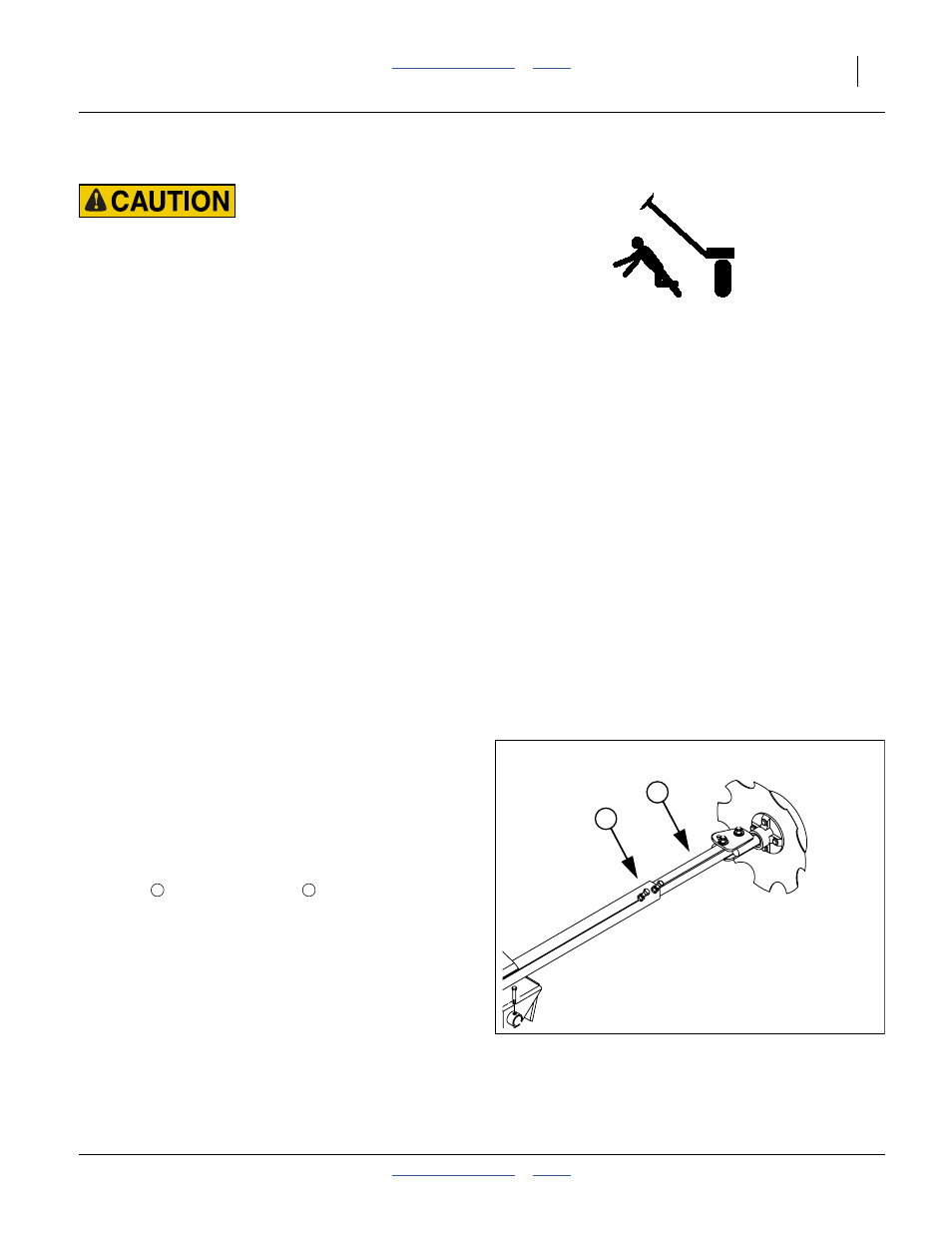

Refer to Figure 61

To adjust marker width, loosen two jam nuts and then

their bolts

and slide arm tube

in or out. Re-tighten

bolts, then the jam nuts.

FigureSpacer

Figure 61

Marker Extension Adjustment

26497

1

2

1

2