Marker speed, Dual-circuit/needle valve speed, Single-circuit/sequence valve speed – Great Plains 2525P Operator Manual User Manual

Page 31

Great Plains Manufacturing, Inc.

Adjustments

27

2013-05-10

118-231M

Marker Speed

The procedure for adjusting marker speed is different for

dual-circuit markers with needle valves and single-circuit

markers with dual sequence valve.

Dual-Circuit/Needle Valve Speed

This applies only to markers plumbed separately (left

and right are each on their own tractor hydraulic circuit).

Refer to Figure 20

A needle valve controls the folding speed. The needle

valve is near the rod end of the marker cylinder.

With tractor idling at a normal operating speed, adjust

marker folding to a safe speed. Turn adjustment knob

clockwise to reduce folding speed or counterclockwise

to increase folding speed. Excessive folding speed could

damage markers and void the warranty.

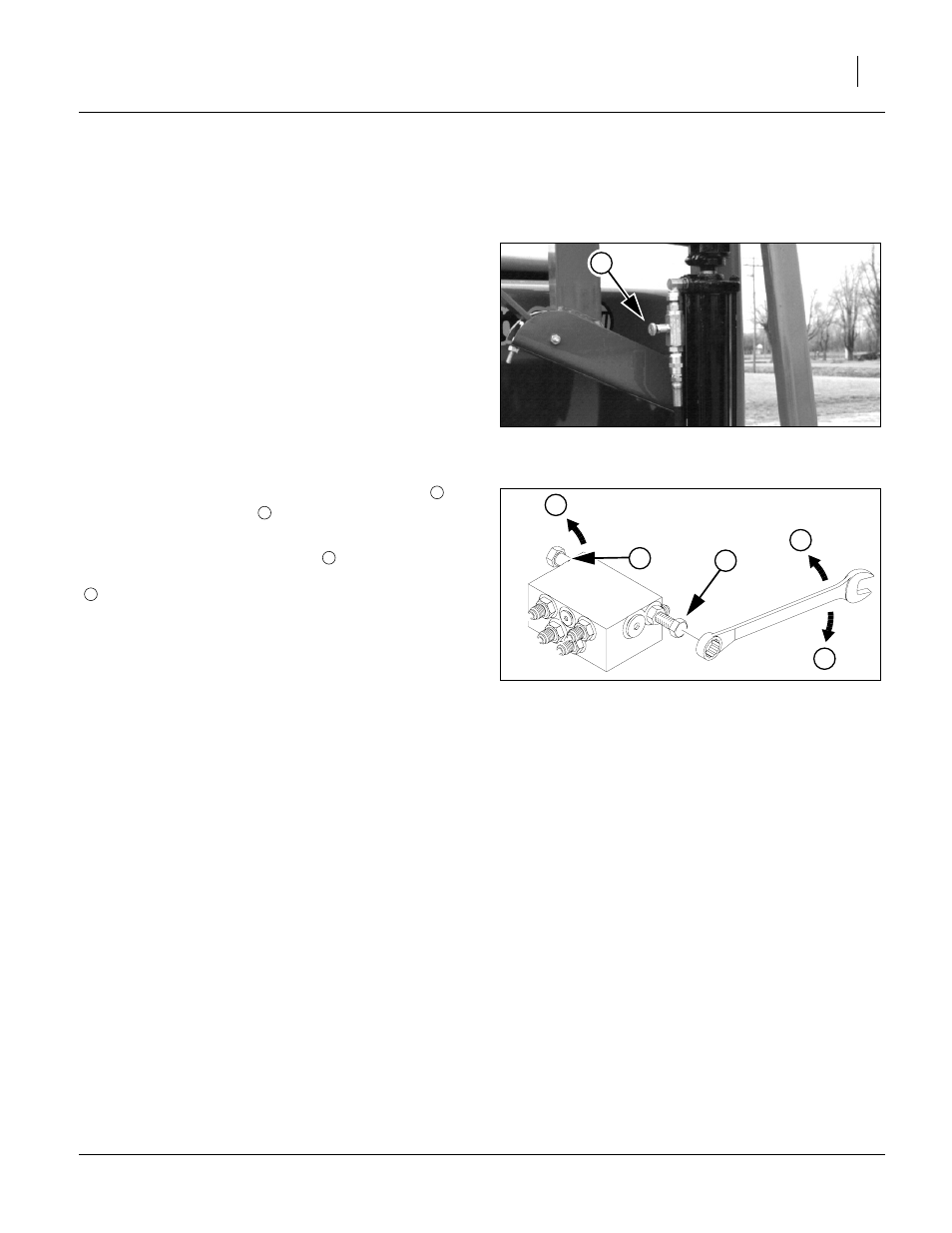

Single-Circuit/Sequence Valve Speed

There is one adjustment screw for unfolding speed

and one for folding speed

. You can identify adjust-

ment screws by markings stamped in valve body.

Turn adjustment screws clockwise (

: slower) to

decrease [un]folding speed and counterclockwise

(

: faster) to increase [un]folding speed.

With tractor idling at a normal operating speed, adjust

marker folding to a safe speed. Excessive [un]folding

speed could damage markers and void the warranty.

After adjusting the folding speed, tighten jam nuts on

hex adjustment screws to hold settings.

Figure 20

Needle valve Adjustment

17620

1

1

2

F

S

S

Figure 21

Sequence Valve Adjustment

14048

1

2

S

F