Meter sample calibration – Great Plains YP40F Operator Manual User Manual

Page 31

Great Plains Manufacturing, Inc.

Adjustments

27

2013-03-25

403-362M

Meter Sample Calibration

18. Weigh any container(s) required to hold the sample

on the scale.

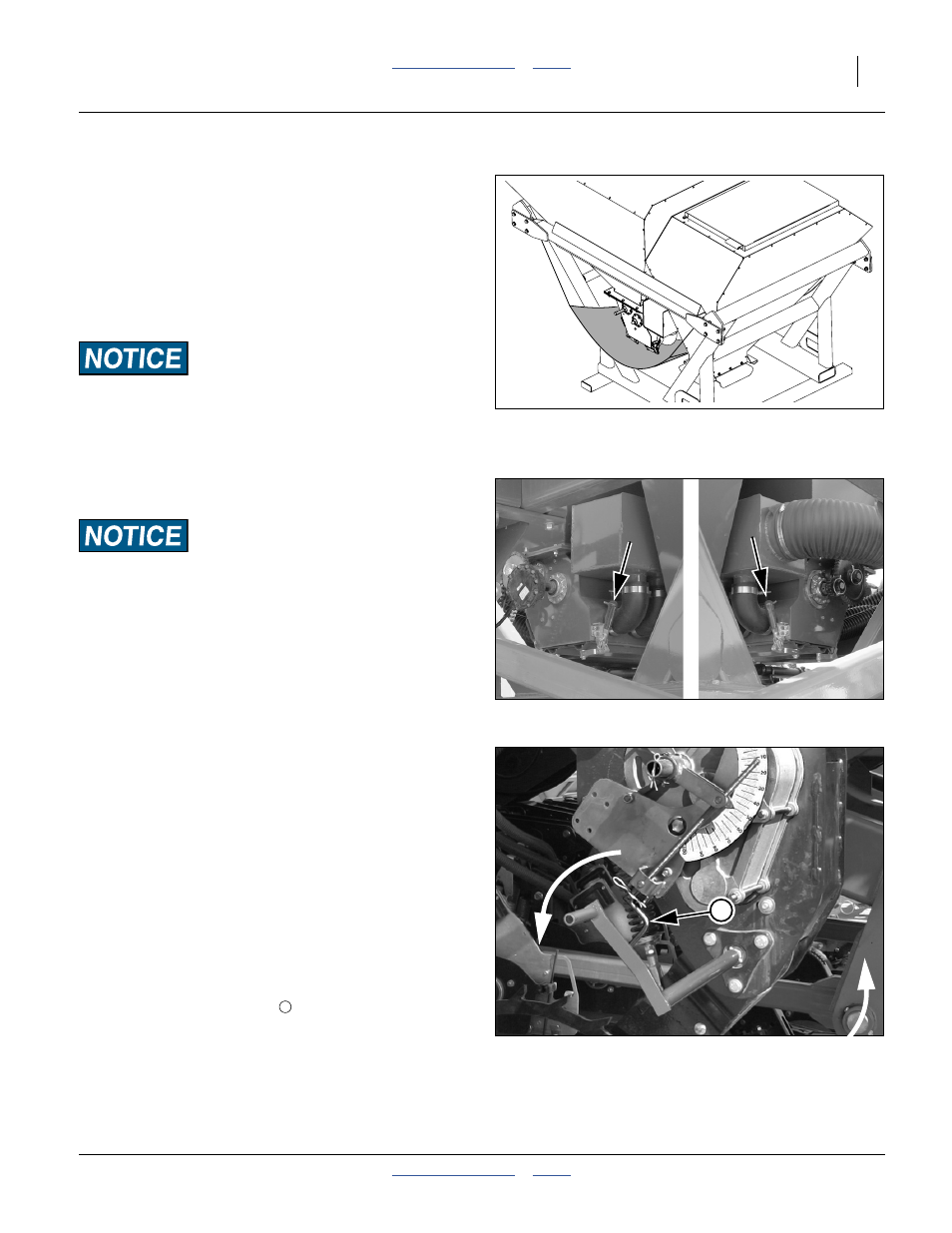

Refer to Figure 14

19. Place a tarp under the fertilizer meter. Support the

corners or edges so that no material can spill.

Refer to Figure 15

20. Open the meter calibration door. The calibration door

is the rear door, furthest from the DRIVING gear.

Material Loss Risk:

Do not open the (forward) door under the DRIVING gear.

This is the clean-out door. Opening this door drains the

hopper. Once the clean-out door is open it is difficult to stop

seed flow until the hopper is empty.

21. Wipe all material off the flanges around the meter

door.

Machine Damage Risk:

Do NOT turn the crank clockwise, or the gearbox may be

damaged. Turn the crank only counter-clockwise (as seen from

planter left, facing planter right).

Refer to Figure 16

22. Turn the crank counter-clockwise until material is

consistently appearing in the collection containers.

Stop cranking.

23. Empty the tarp and return it to the collection position.

24. Turn the crank for the number of revolutions

necessary to simulate the area to sample, as shown

in chart on page 25.

25. Weigh the collected sample. Subtract the weight of

any container required at the scale.

26. Calculate the material rate per the instructions and

27. If the results differ from your target by more than a

few percent, adjust the gearbox setting per the

instructions on page 27.

Then measure another sample starting at step 23.

Meter Sample Close-Out

28. Pin the gearbox adjuster

in position

29. Remove the calibration crank.

Figure 14

Meter Sample Collection

31105

Figure 15

Calibration Door Handles

31101

Figure 16

Calibration Crank (Meter)

31000

3

3