Great Plains SR5030 Operator Manual User Manual

Page 23

21

Section 5 Maintenance and Lubrication

4/12/05

SR5030 Split-Row Planter 401-140M-A

Great Plains Mfg., Inc.

4.

Reassemble finger housing onto carrier plate. When

reassembling, align notch in finger-housing cam (1)

with notch on bearing housing so finger housing is

flush with the carrier plate. The meter will function im-

properly if the notches are not aligned.

17745

Figure 5-4

Meter Reassembly

5.

With finger assembly against carrier plate, tighten ad-

justing nut until it is snug, then turn an additional one-

third turn. Proper torque is 22 to 25 inch-pounds at the

meter-input shaft.Turn meter by hand to make sure

the meter is not over tightened.

IMPORTANT: Check tightness of the adjusting nut

on the meter after the first day of operation and peri-

odically thereafter.

6.

Reassemble cage nut and cotter pin. Reassemble

baffle and attach meter to hopper.

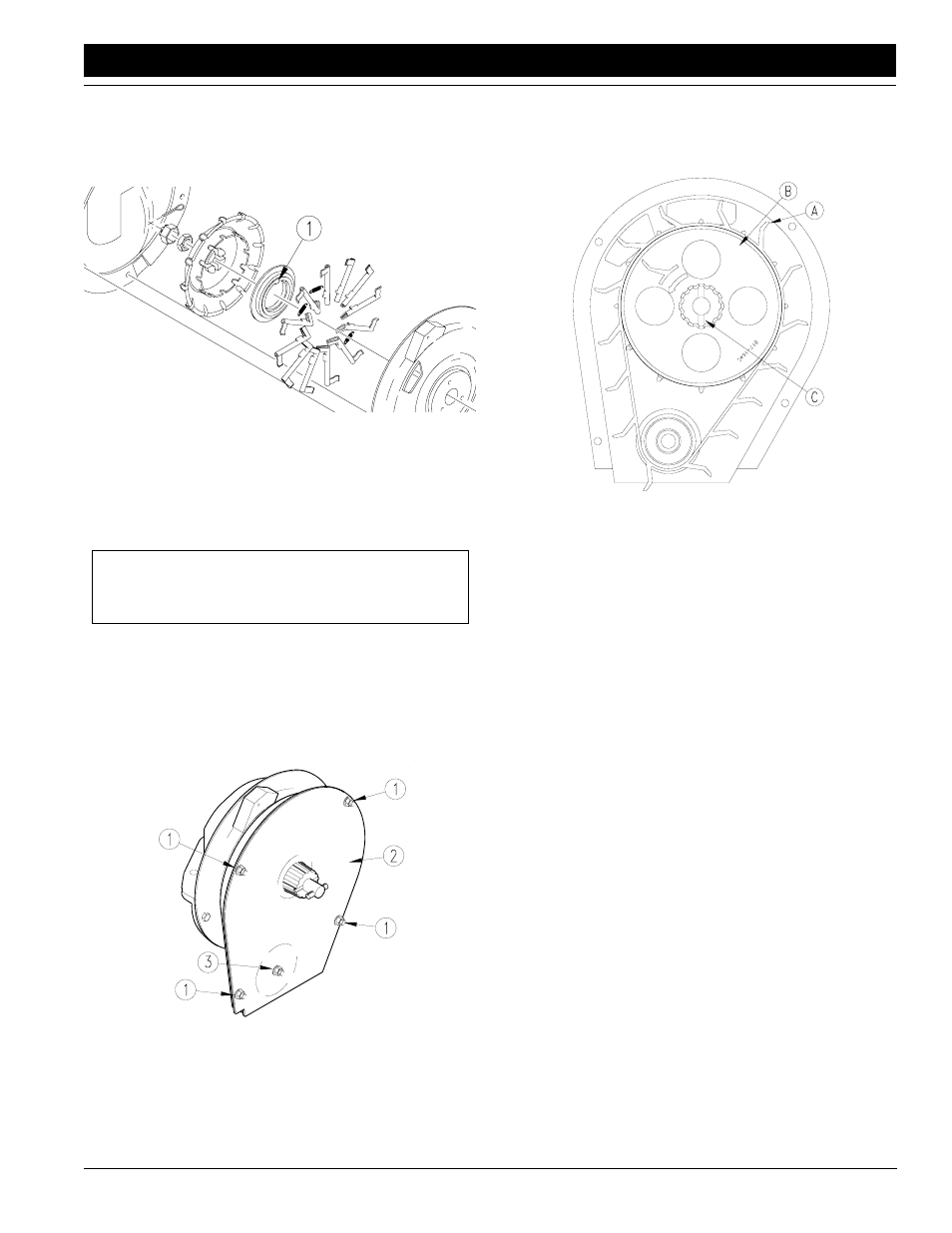

Periodically check the meter belt. Refer to Figure 5-5.

1.

Remove four bolts (1) from belt housing (2). Remove

bolt holding the belt roller (3). Remove belt housing.

2.

Inspect belt. Replace belt if necessary.

14966

Figure 5-5

Belt Inspection

3.

To replace a worn or broken belt, refer to Figure 5-6.

Be certain paddles (A) are oriented as shown. Belt

drive wheel (B) may be removed by removing spring

pins (C).

15049

Figure 5-6

Belt Installation

4.

Reassemble meter in reverse order.

Opener Disks, Scrapers and Gauge Wheels

1.

Remove side-gauge-wheels from arms to access

opener disks and scrapers.

2.

With the unit raised, check blade spreader (1) for

wear. Replace spreader if it is 1/2 inch wide or narrow-

er. To replace, remove disk blade. Drive out roll pins

(2) and install a new spreader.

3.

Check disk blades (3) for wear.Replace blades if worn

to a diameter of 14 1/2 inches or less.

4.

When reinstalling disk blades, put two shims between

bearing and shank on one blade. Tighten bolt. On op-

posite side, reinstall blade with two (4) shims between

bearing and shank. Tighten bolt.

5.

Check contact point between disk blades. Place a

piece of paper in top gap between disks blades. Bring

paper down until it stops. In lower gap place another

piece of paper. Bring paper up until it stops. Measure

the distance between two pieces of paper. The dis-

tance must be between 1/2 and 1 3/4 inches. Add or

remove shims as needed to get the correct contact

point.

6.

Check that outside disk scrapers (5) are formed to

disk blades to help remove any mud. Bend and twist

scrapers to fit blades as necessary. After every 200

acres of planter operation, check outside scrapers for

proper adjustment and wear. Replace outside scrap-

ers as necessary.