196s shank, Depth gauge, 196s shank depth gauge – Great Plains TC5319 (S/N A1420X+) Predelivery Manual User Manual

Page 18

14

TC5109-5323

Great Plains Manufacturing, Inc.

566-224Q

03/06/2014

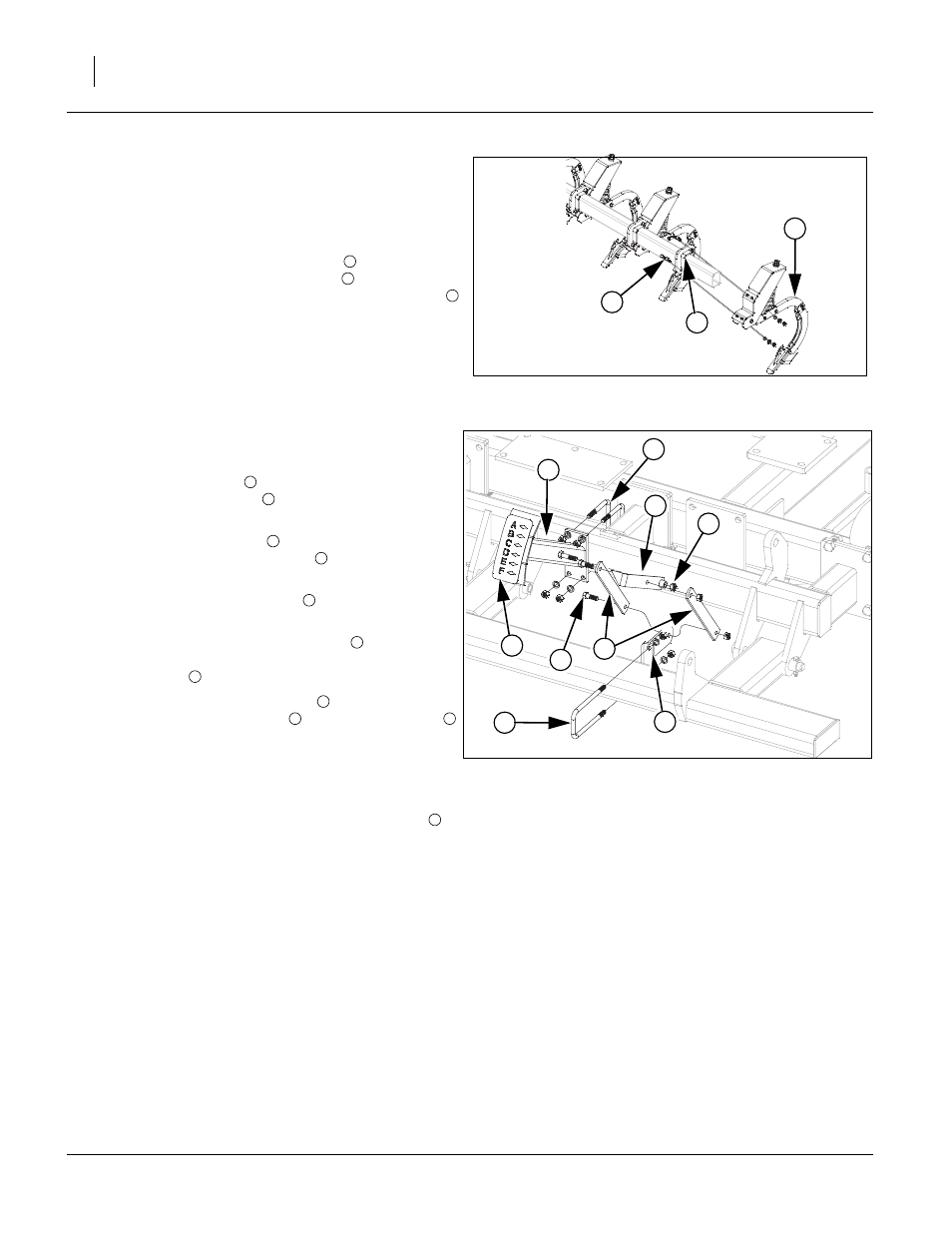

569-196S Shank

Note: The 569-196S shank mount assemblies will be

shipped in a wooden box. See machine layouts in

Appendix for proper shank placement.

Refer to Figure 15

57. Install the shank mount assemblies

to the rear side

of tubes. Install front mount bracket

on front of

tubes, align holes, secure with 3/4 x 2 1/2 hex bolts

,

3/4 lock washers and 3/4 nuts. Slide these two parts

over frame tube in proper location.

58. Tighten all bolts to specs, See “Torque Values Chart”

Depth Gauge

Refer to Figure 16

59. Install the link mount

to the center gang bar with 1/

2 x 3 1/32 x 7 1/4 u-bolt

, 1/2 lock washers and 1/2

nuts.

60. Install leveling weldment

to the center gang mount

with 1/2 x 5 1/32 x 4 1/2 u-bolts

, 1/2 lock washers

and 1/2 nuts.

61. Slide the depth gauge pointer

over the leveling

weldment bolt, secure with 1/2 lock nut.

62. Align one set of holes in the two links

, one on each

side of the depth gauge pointer hole 5, secure with 1/

2 x 1 1/2 bolt

and 1/2 lock nut.

63. Attach the other end of the links

, one on each side

of the hole in the link mount

with 1/2 x 1 1/2 bolt

and 1/2 lock nut.

64. Tighten all u-bolts to specs, See “Torque Values

Chart” on page 17. Tighten the three lock nuts up

snug, but be sure the links will pivot.

65. Clean the surface where TC depth coulter decal

goes and peel backing off of decal and fasten decal

on plate. Firmly press decal to get all air bubbles out.

Figure 15

596-196S Shank

42048

1

3

2

1

2

3

Figure 16

Depth Gauge

41668

4

7

8

1

5

2

3

9

6

1

2

3

4

5

7

8

7

1

8

9

- TC5323 (S/N A1420X+) Predelivery Manual TC5321 (S/N A1420X+) Predelivery Manual TC5317 (S/N A1420X+) Predelivery Manual TC5315 (S/N A1420X+) Predelivery Manual TC5313 (S/N A1420X+) Predelivery Manual TC5115 (S/N A1420X+) Predelivery Manual TC5113 (S/N A1420X+) Predelivery Manual TC5111 (S/N A1420X+) Predelivery Manual TC5109 (S/N A1420X+) Predelivery Manual