Marker maintenance, Marker speed adjustment, Marker shear bolt – Great Plains 1300 13-Foot Operator Manual User Manual

Page 48: Marker grease seal cap check, Marker speed adjustment marker shear bolt

44

1300 and 1300F

Great Plains Manufacturing, Inc.

175-157M

2014-04-15

Marker Maintenance

Marker Speed Adjustment

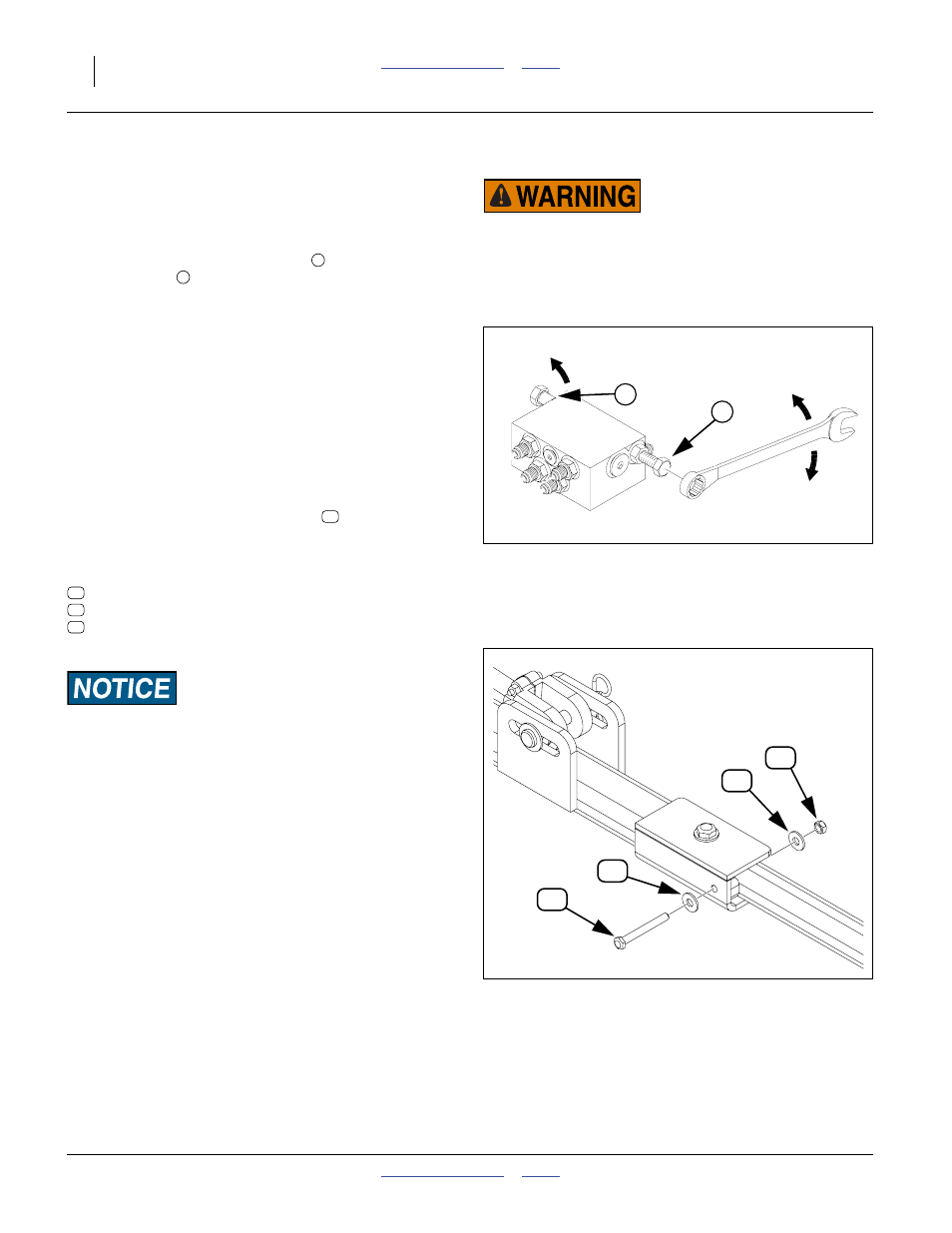

Refer to Figure 42

Adjust folding speed for dual markers with hex

adjustment screws on sequence valve body. There is an

adjustment screw for raising speed

and one for

lowering speed

. You can identify adjustment screws

by markings stamped in the valve body.

Turn adjustment screws clockwise to decrease folding

speed and counterclockwise to increase folding speed.

With tractor idling at normal operating speed, adjust

marker folding to a safe speed. Excessive folding speed

could damage markers and void the warranty.

After adjusting folding speed, tighten jam nuts on hex

adjustment screws to hold settings.

Marker Shear Bolt

Refer to Figure 43

If a marker gets caught or hits an obstruction, it is

designed to fail a Grade 5 shear bolt

at the fold, pivot

on a pin, and swing back. If the bolt shears, chances are

the washers and lock nut will be lost as well.

The replacement parts are:

802-197C HHCS 5/16-18X2 3/4 GR5

803-011C NUT LOCK 5/16-18 PLT

804-010C WASHER FLAT 5/16 USS PLT

Install the replacement bolt from implement front.

Equipment Damage Risk:

Using a lower Grade bolt can result in nuisance shears.

Using a higher Grade bolt can result in machine damage.

Using lower strength washers can result in machine damage.

Using a plain nut can result in non

-shear arm swings as the

nut loosens.

If exact replacement parts are not immediately available,

temporarily substitute a metric M8 Class 8.8 bolt, heavy

duty washers and lock nut. If a lock nut is not available,

insert a split lock washer in between the nut and the rear

flat washer.

Marker Grease Seal Cap Check

If grease-seal cap for marker-disk-hub bearings is

damaged or missing, disassemble and clean hub.

Repack with grease and install a new seal or grease cap.

Figure 42

Marker Extension Adjustment

14048

F

S

S

1

2

Crushing and Sharp Object Hazards:

Keep all persons well clear of markers during lift/lower

marker fold/unfold operations. Un

-pinned markers fold and

unfold when the lift circuit is extended or retracted. Markers

have multiple pinch points. Lowering arms can crush. Marker

disks are sharp.

1

2

31

31

32

33

Figure 43

Marker Shear Bolt

36276

32

31

33

33