Bleeding lift and marker hydraulics – Great Plains 1300 13-Foot Operator Manual User Manual

Page 47

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

43

2014-04-15

175-157M

Bleeding Lift and Marker Hydraulics

To function properly, the hydraulics must be free of air.

With air in the system, the hydraulics will move in jerky,

uneven motions. If you install or replace a hydraulic

component, follow these steps.

1.

Check the fluid level in the tractor hydraulic reservoir.

Bleeding the hydraulics with a low fluid level will draw

air into the system.

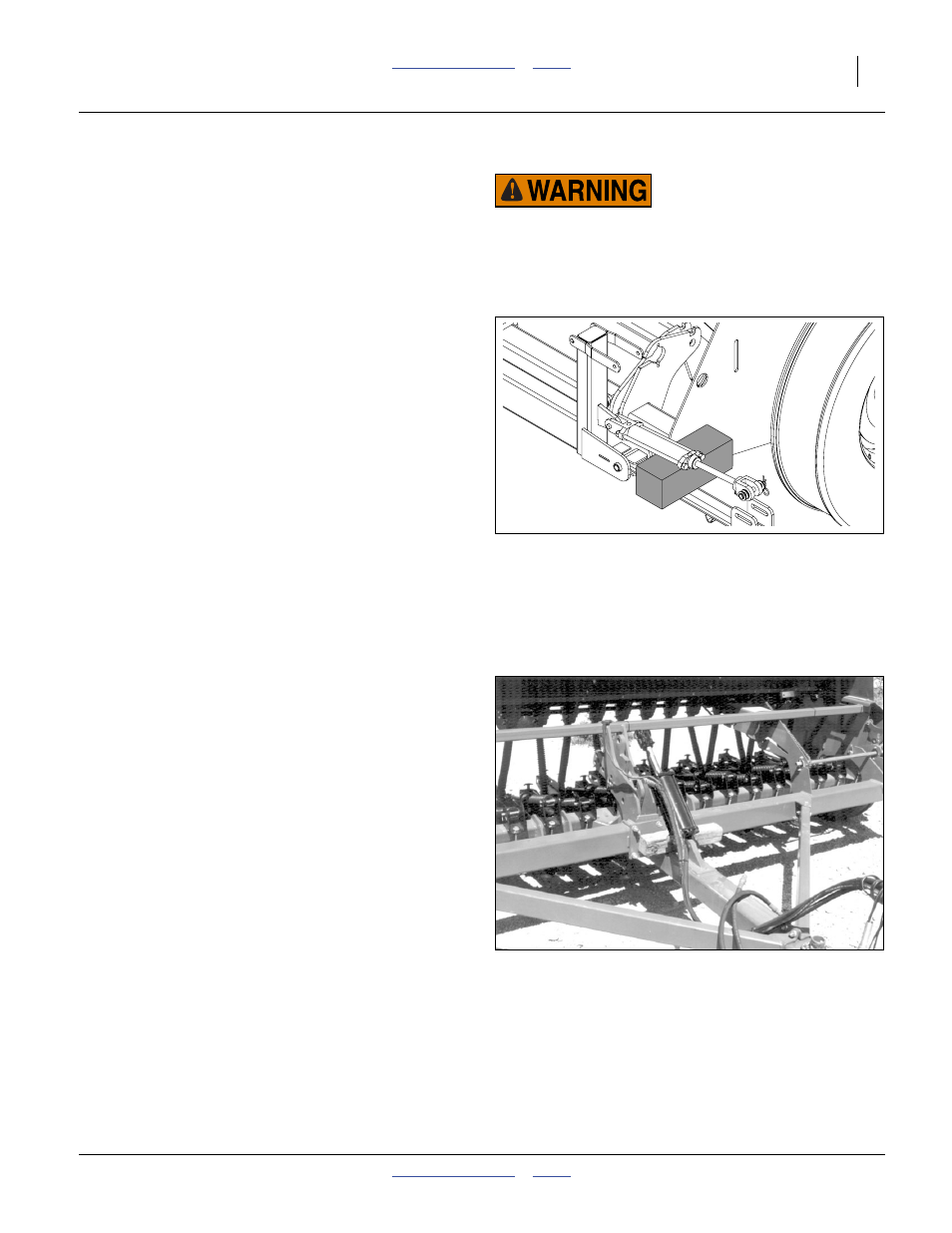

Refer to Figure 40 (depicting a cylinder support block

- you

can also set the cylinder vertically, pinned in the mount)

2.

If markers are installed, disconnect the rod ends of

both cylinders and lay the markers on the ground.

Support the cylinders so that the rod ends are free of

obstructions.

Refer to Figure 41

3.

Lower the openers to the ground. Unpin the rod end

of the cylinder from the floating lug. Wire, block up, or

otherwise safely support the cylinder so the rod will

not contact anything when fully extended.

4.

Operate the lift circuit to retract the lift cylinder.

If markers are installed, this will also retract one

marker cylinder.

5.

Loosen a JIC or NPT connection between the hoses

and fittings of:

• lift cylinder base end (cylinder retracted)

• marker cylinder base end (cylinder retracted)

6.

With the tractor idling, slowly work the tractor remote

lever as if extending the lift cylinder. As oil seeps

from a fitting, stop extension and tighten each hose

connection.

7.

Continue working the lever until the lift cylinder and

active marker cylinder rods are completely extended.

8.

Loosen a JIC or NPT connection between the hoses

and

• lift cylinder rod-end fitting

• marker cylinder rod end

9.

With the tractor idling, slowly work the tractor remote

lever in the opposite direction as if retracting the lift

cylinder. As oil seeps from a fitting, stop retraction

and tighten each hose connection.

10. If markers are installed, repeat step 4 through step 9

for the other marker side.

11. Reconnect the marker cylinders. Cycle the system to

fold and lock each marker with its pin.

12. Continue working the lever until the lift cylinder is

completely extended. Re-pin the cylinder to the

floating lug.

Note: When bleeding cylinders, begin with them

retracted (loosening base end connection), and

end with them extended (loosening rod end

connection).

Figure 40

Marker Cylinder Bleed

36276

Crushing and Sharp Object Hazards:

Keep all persons well clear of markers during lift/lower

marker fold/unfold operations. Un

-pinned markers fold and

unfold when the lift circuit is extended or retracted. Markers

have multiple pinch points. Lowering arms can crush. Marker

disks are sharp.

Figure 41

Opener Lift Cylinder Supported

16675