Opener frame down-force, Spring down pressure-all openers, Spring down pressure–all openers – Great Plains 1300 13-Foot Operator Manual User Manual

Page 36: Opener frame down, Force

32

1300 and 1300F

Great Plains Manufacturing, Inc.

175-157M

2014-04-15

Opener Frame Down

-

Force

To properly adjust seeding depth, you need an

understanding of how the opener frame, opener springs,

disks and press wheels work. The opener frame

adjustment affects all rows at once.

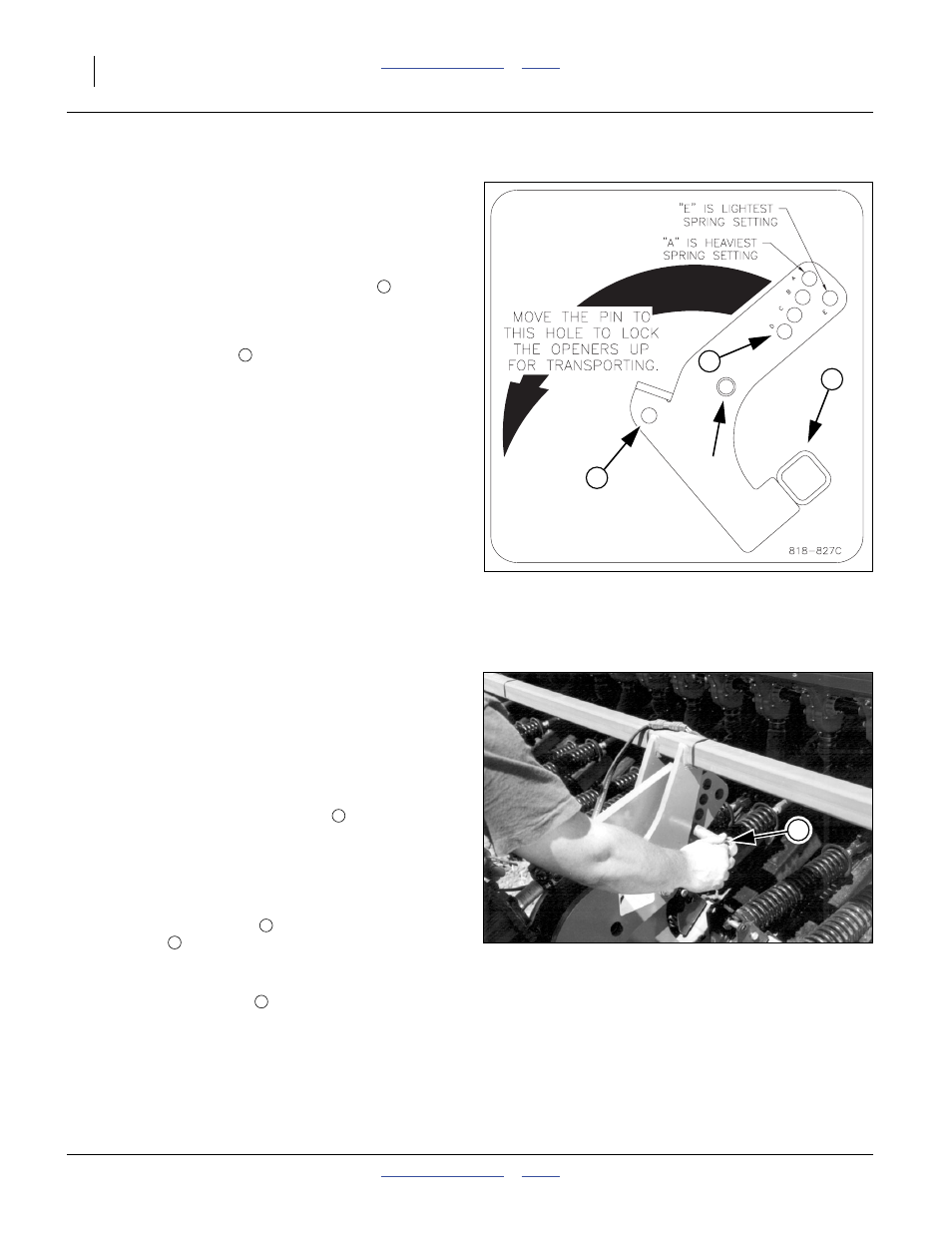

Refer to Figure 27 and Figure 28

The openers are mounted on a pivoting tube

.

A hydraulic cylinder mounted on a floating lug controls

the openers. Springs on the opener bodies provide down

pressure for the opener disks to cut a seed furrow. An

adjustable pivot-stop pin

floating lug and thereby controls spring length and down

pressure on all openers.

Changing the position of the pivot-stop pin changes

opener down-pressure across the drill. You can also

change the spring length or mounting height of individual

openers, such as in tire tracks.

Press wheels are mounted on the opener bodies behind

the opener disks, and perform two functions:

• They close the furrow and firm the seed bed. To

provide consistent seed firming, the press wheels are

free to move down from their normal operating

position. This maintains pressing action even if the

opener arm lifts at obstructions.

• The press wheels control opener depth. The higher

the press wheels run, the deeper seed is placed.

Spring Down Pressure–All Openers

The amount of down pressure needed for the opener

disks to penetrate the soil varies with field conditions.

The objective in selecting a pivot-stop pin hole, and a

press wheel height, is to achieve the desired planting

depth while keeping the drill frame and the row unit

frames level with the ground.

Note: The setting of the pivot-stop pin

interacts with

the setting of the press wheel height. When

adjusting one, recheck the other.

To increase or decrease all-rows spring down pressure:

1.

Raise the drill (to free the pin).

2.

Move the pivot-stop pin

.

The holes

in the floating lug are lettered:

A provides the greatest down pressure and

E provides the least.

As the pin is moved to hole

for transport, keep records

of what hole is optimal for fields and conditions worked.

Note: To maintain consistent opener down pressure, fully

extend the hydraulic cylinder each time you lower

the openers.

Figure 27

Down-Pressure Decal

818827C

1

3

Pivot

Point

4

1

2

Figure 28

Adjusting Down-Pressure Pin

16652

2

2