Rolling harrow (optional) – Great Plains 4000TM Predelivery Manual User Manual

Page 35

Great Plains Manufacturing, Inc.

Assembly

31

11/06/2012

586-288Q

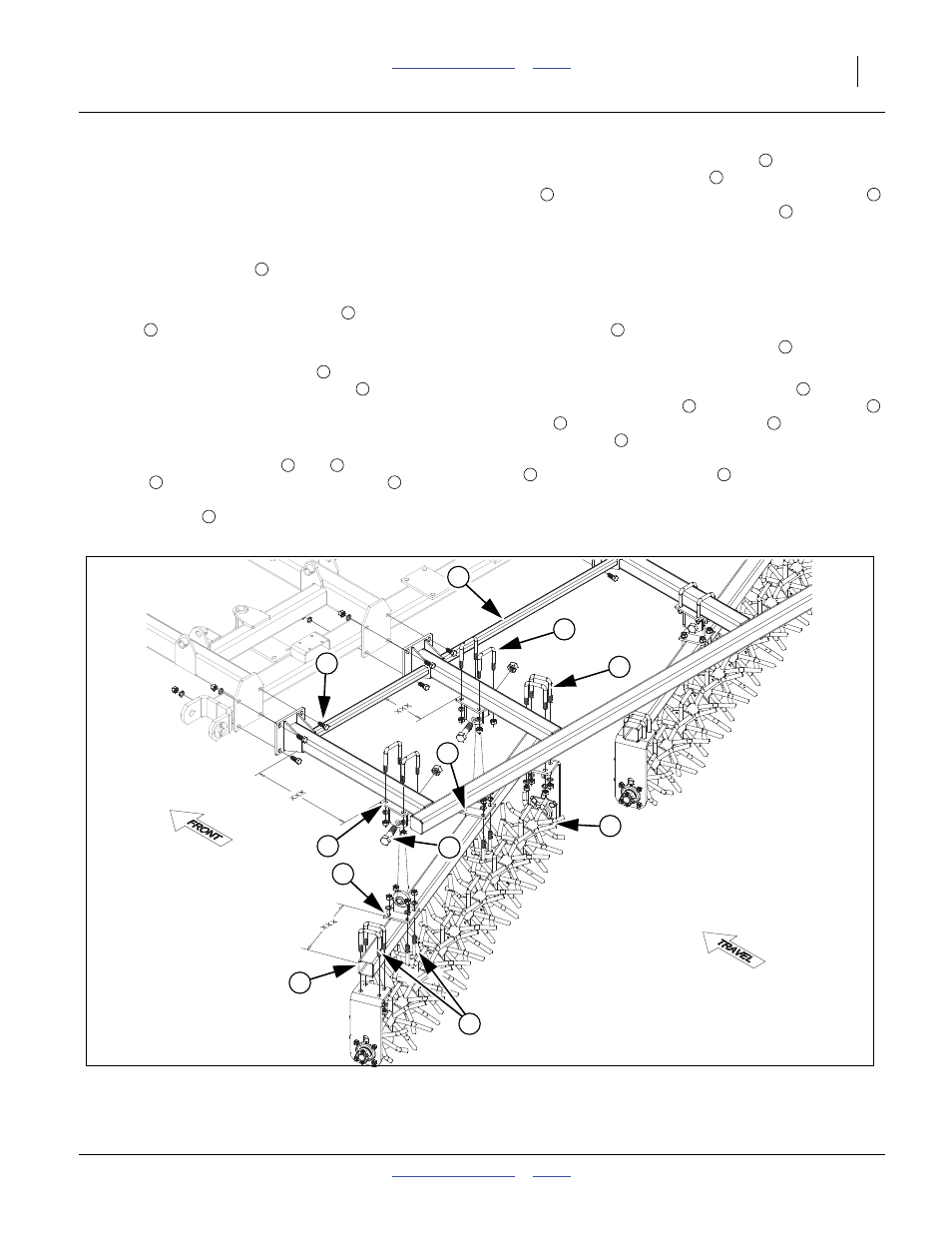

Rolling Harrow (optional)

Note: It is very important to install the rolling harrow

assembly in the order shown below and go to the

rolling harrow placement drawing, see “Layout

Section” of this manual for proper dimensions

where it is marked xxx in drawing below. The roll-

ing harrow bracket

dimensions are coming off

of rear, front tube of drag frame

to front of plate

of rolling harrow bracket

. The ball joint bracket

is dimensioned off of end of rolling spike tube

to side of plate on ball joint bracket

(dimensions

in layout drawings may come off either end of

tube). For complete parts breakdown see “Attach-

ment Section” of Parts Manual.

Refer to Figure 36

122.Start by installing the drag frames

with 3/4 x 2 hex

bolts

, 3/4 lock washers and 3/4 nuts. Torque bolts

to 265 ft-lb.

123.Attach rolling harrow brackets

in appropriate loca-

tion with 5/8 x 3 1/32 x 4 1/2 u-bolts

, secure with

5/8 lock washers and 5/8 nuts. Adjust the brackets to

dimensions shown in layout drawings and torque u-

bolts to 150 ft-lb.

124.Attach ball joint brackets

and

to rolling spike

tubes

with 5/8 x 3 1/32 x 4 1/2 u-bolts

, secure

with 5/8 lock washers and 5/8 nuts. Place left ball

joint brackets

in proper location from layout draw-

ing and torque u-bolts to 150 ft-lb. Leave right ball

joint bracket

loose, as it may need move a little to

bolt up to right rolling harrow bracket

.

125.Carefully lower machine down or use fork lift (if avail-

able) to raise rolling harrow assemblies

to attach

rolling harrow brackets

. Align ball joint brackets

and

to rolling harrow assemblies

, secure with 1

x 4 hex bolts

and 1 nylon lock nut. Torque bolts to

645 ft-lb. Also torque the 5/8 x 3 1/32 x 4 1/2 u-bolts

in right ball joint brackets

to 150 ft-lb.

126.Check to see that all bolts have been tightened to

specs, See “Torque Values Chart” on page 36.

3

1

3

6

8

6

1

2

3

4

6

7

8

4

6

7

3

9

3

6

7

9

5

4

7

Figure 36

Rolling Harrow

42439

1

9

4

2

4

5

7

8

6

3

4