Front gang assembly 3500-4000 – Great Plains 4000TM Predelivery Manual User Manual

Page 21

Great Plains Manufacturing, Inc.

Assembly

17

11/06/2012

586-288Q

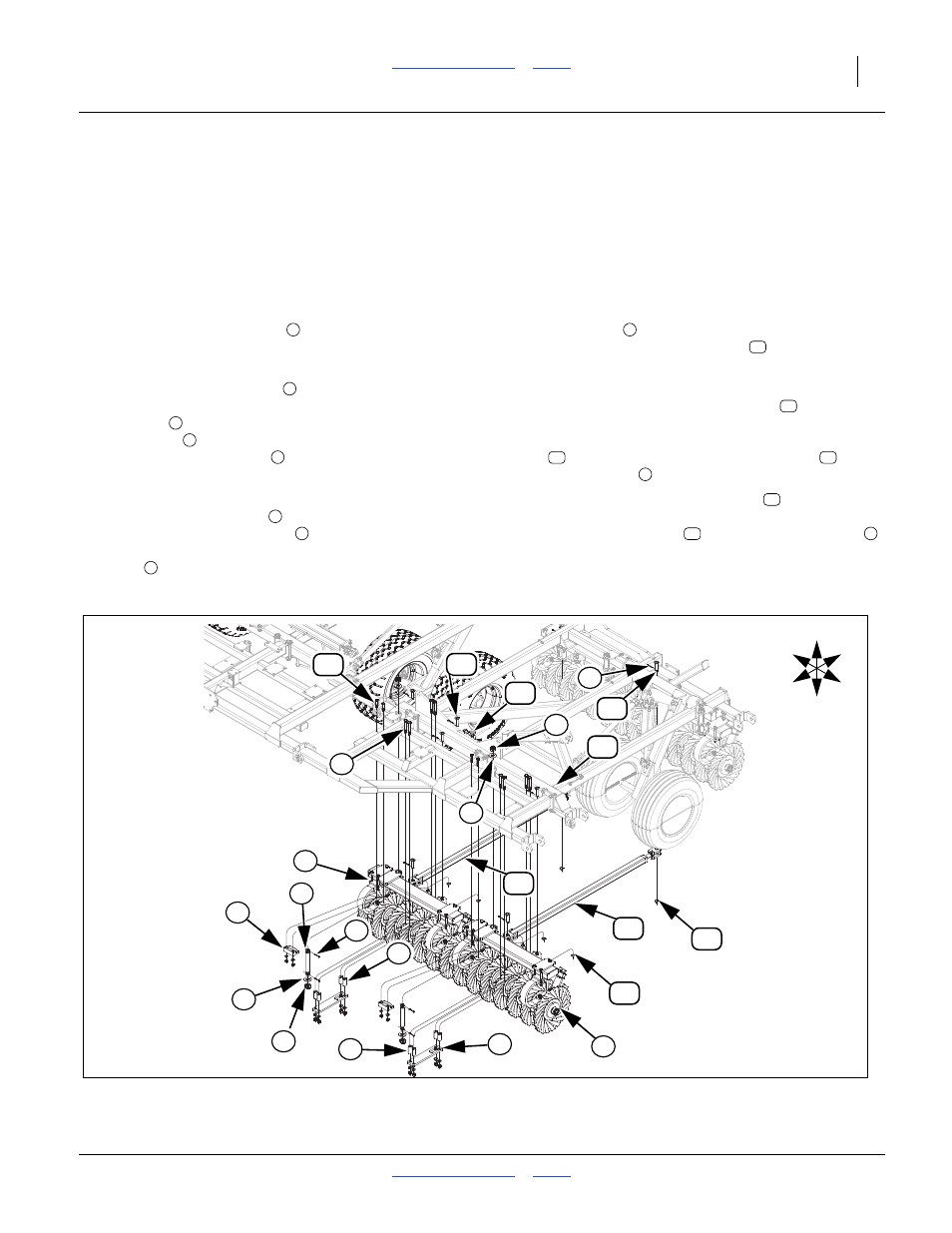

Front Gang Assembly 3500-4000

Note: The center and wing gang assemblies will install

the same. The only difference is, that the gang

assemblies and turnbuckles will be different from

center to wings. Cylinder base end will be hooked

to ear on center and wing frames. See machine

layouts in appendix section for proper gang loca-

tions. See wing gang bar & fold assembly 3500-

4000 for complete parts breakdown. You will prob-

ably need to hook all hydraulics up, See “3000

Hydraulic Wing Lift & Gangs” on page 18

through See “4000 Hydraulic Fold” on page 24

and charge systems before installing gang assem-

blies, See “Purging Hydraulic System 3000-

4000” on page 27.

Refer to Figure 21

75. Position gang assemblies

in correct location on

floor or ground and carefully lower machine down to

gang assemblies.

76. Install the gang pivot bolt

through aligned tubes

on gang bars and brace bars. Secure with 1 1/4 flat

washers

(one on top and one on bottom), 1 1/4

slotted nut

(one on top and one on bottom) and

two 3/16 x 2 cotter pins

. Tighten bolts snug,

torque to 350 to 400ft-b. Cotter pins may be bent

over to secure.

77. Install the round tubes

(four on each gang bar)

between bottom front plate

(slotted hole toward

rear) and plate on brace bars. Install the 3/4 x 6 hex

bolts

, 3/4 lock washers and 3/4 nuts.

78. Install bracket

on bottom side of gang bar plate,

secure with 5/8 x 3 1/2 hex bolts

, 5/8 lock wash-

ers and 5/8 nuts.

79. Install either 586-444S turnbuckle assembly (center

section) or 586-445S (wing sections)

, adjustable

end on ear on front of rear gang bars and fixed end

on ear of front gang bars. Secure with 1 x 3 1/4 clevis

pin

, 1.5 x 1.00 x 0.075 machine washer

and 3/

16 x 2 cotter pin

.

80. Now the rod end of gang cylinders

may be

hooked up with the 1 x 3 1/8 clevis pin, 1.5 x 1.00 x

0.075 machine washer

and 3/16 x 2 cotter pin

.

81. Bolt may be tightened to specs, See “Torque Values

Chart” on page 36 and all cotter pins may be bent.

1

2

3

4

5

6

7

8

9

10

11

12

13

5

14

13

5

Figure 21

Front Gang Assembly 3500-4000

42881

9

8

1

7

1

3

6

14

13

11

13

15

10

6

2

5

U

D

F

B

L

R

4

12

14

5

11

4

3