Great Plains 2515P Marker Option User Manual

Page 2

113-685M

3/19/2003

Great Plains Mfg., Inc.

Marker Option

2

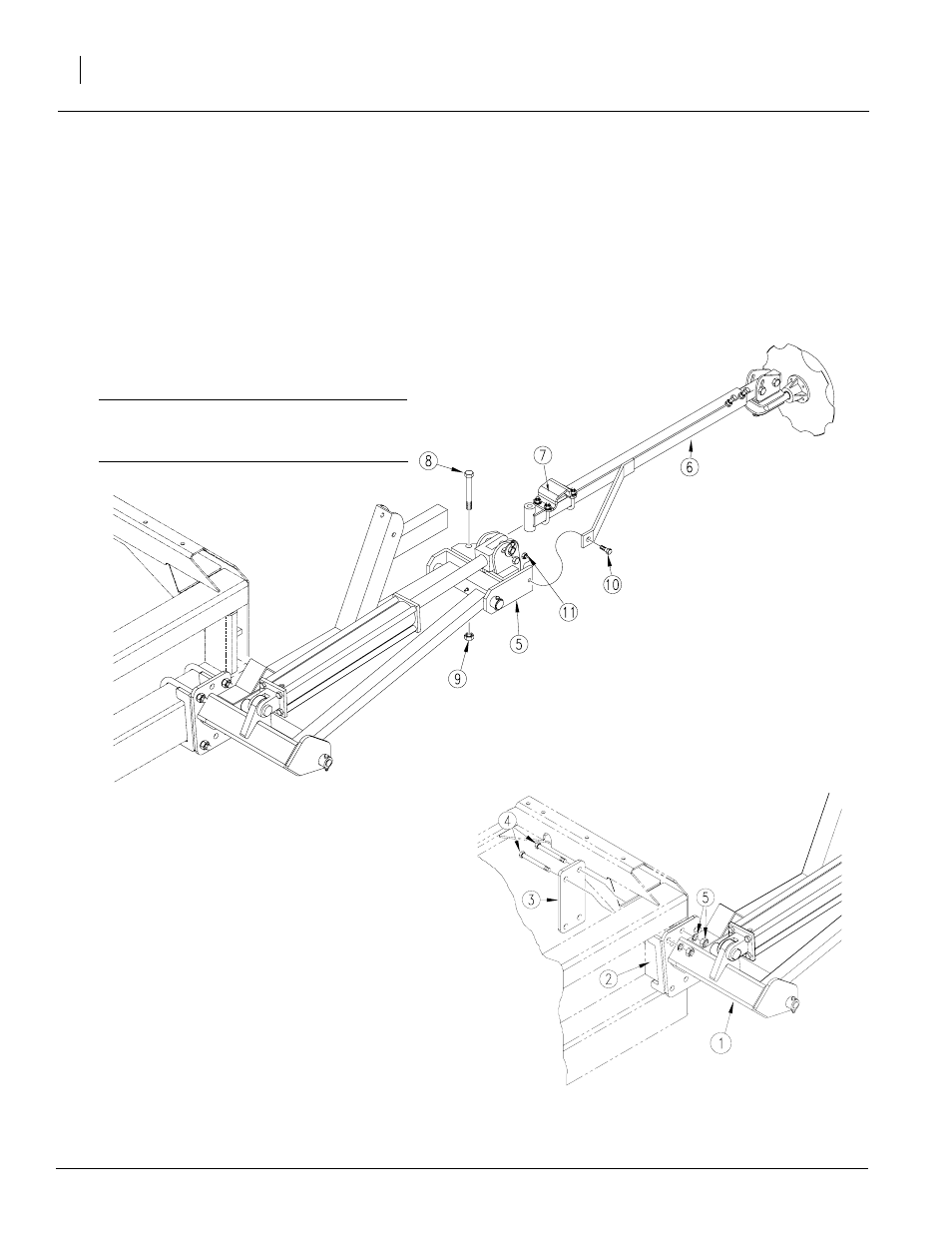

Refer to Figure 2.

Figure 2

Marker Breakaway Assembly

18534

3.

Remove port plugs on cylinder and carefully

unfold first marker section. Rotate hinge sec-

tion (5) into a horizontal position.

4.

Align holes of break-away section (6) with

holes in hinge section. Bolt sections together

with stop block (7) on break-away section fac-

ing up. Use 5/8 inch pivot bolt (8), lock nut (9),

3/8 x 1 3/4 inch, grade 2 shear bolt (10) and

lock nut (11).

IMPORTANT: Be sure shear bolt is a grade 2

bolt. Failure to use a grade 2 bolt can cause

marker damage.

5.

Repeat steps for other marker.

6.

Adjust marker disks so they are square with

ground when markers are lowered in field po-

sition. Refer to Marker Adjustments in opera-

tor’s manual.

Marker Assembly, 1515 Alternate Location

If you will be using the 15-foot bean machine with

a dual-tire tractor, mount markers on the 2 x 5 inch

vertical frame tube to accommodate the gauge

wheels. To mount markers in alternate location,

you will need Great Plains kit 113-686A.

Refer to Figure 3.

1.

Lower bean machine into field position. Allow

9 feet on each end of bean machine for mark-

er assembly.

2.

Mount first marker section (1) on 2 x 5 inch

vertical frame tube (2). Place mounting plate

(3) behind vertical tube. Use 3/4 inch bolts (4)

through marker and mounting plate. Secure

bolts with lock washers and nuts (5).

3.

Complete steps 3 through 6 on page 2 to

complete marker assembly.

Figure 3

1515 Alternate Mounting

17814