Treader gang assembly (optional) – Great Plains 9756PP Predelivery Manual User Manual

Page 16

12

9322-9756PP

Great Plains Manufacturing, Inc.

580-043Q

02/17/2014

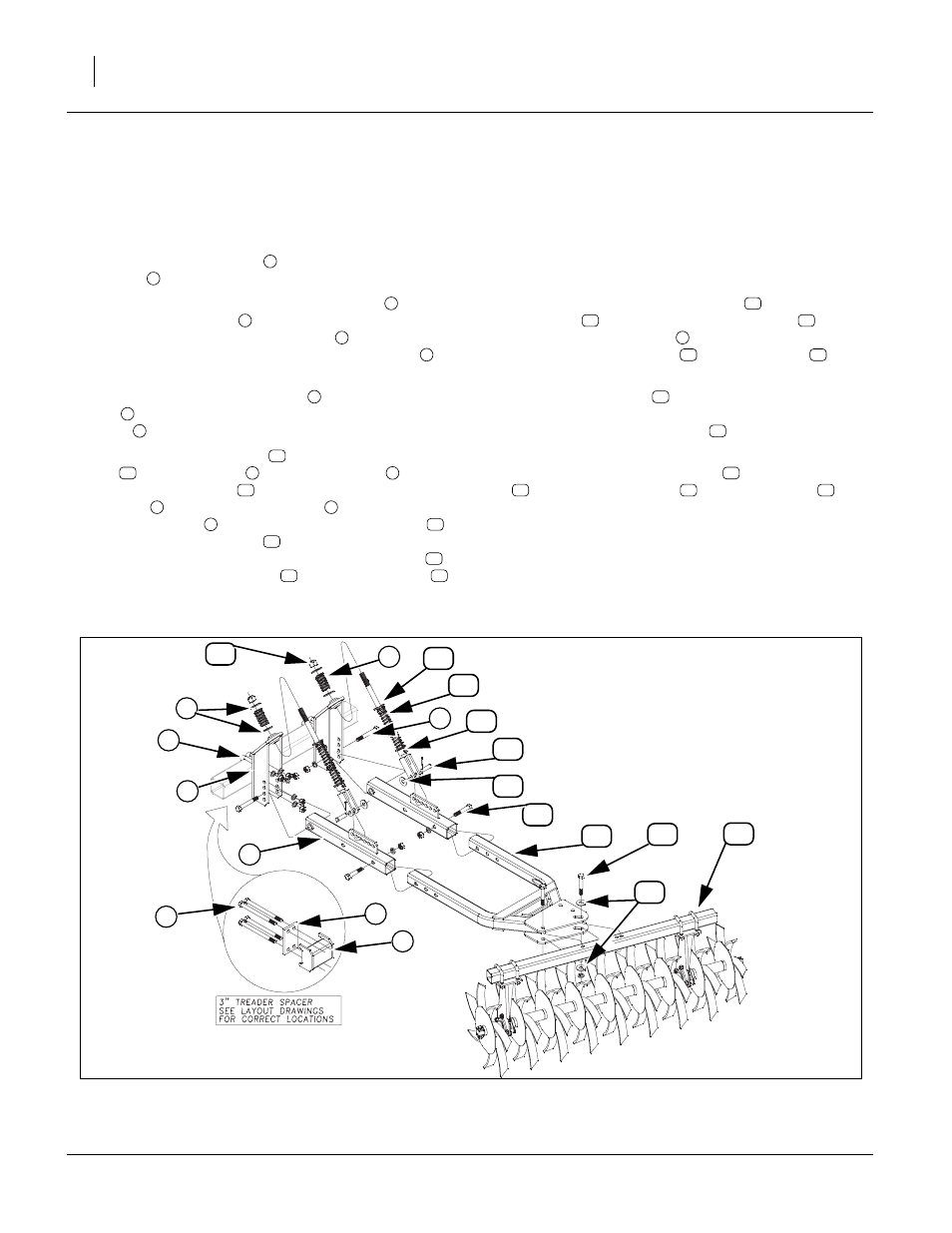

Treader Gang Assembly (optional)

Note: For treader gang placement see “Layout Section”

of this manual. For complete parts breakdown see

“Attachment Section” of Parts Manual.

Refer to Figure 11

40. Install mounting bracket

with 3/4 x 4 1/32 x 5 3/8

u-bolts

, 3/4 lock washers and 5/8 nuts.

41. On models 9744-9756 the treader spacer

and

treader spacer plate

will need installed on center

section between mounting bracket

and rear tube

of center frame. Secure with 3/4 x 10 hex bolts

, 3/

4 lock washers and 3/4 nuts.

42. Attach treader mount brackets

to mounting brack-

ets

, (2nd hole from bottom) with 3/4 x 5 1/2 hex

bolts

, secure with 3/4 lock washers and 3/4 nuts.

43. Remove 1 nylon lock nut

from clevis bolt assem-

bly

, 1 flat washers

and upper spring

. Slide

clevis bolt assembly

through uniball of heavy fold

bracket

, secure 1 flat washers

(one each side

of upper spring

), secure with 1 nylon lock nut

.

Tighten 1 nylon lock nut

down to where there is

about 2 threads showing above nut. Slide collar

up on clevis bolt assembly

until slower spring

is snug against bottom of uniball but do not com-

press spring and tighten set screw in collar to

secure.

44. Remove the 3/4 x 2 1/2 clevis pin

from clevis bolt

assembly

. Attach clevis bolt assembly

to

treader mount brackets

(3rd hole from front) with

the 3/4 x 2 1/2 clevis pin

, 3/4 flat washer

and 1/

8 x 1 cotter pin. Bend cotter pin to secure.

45. Slide treader mount

(with hole position and

angled plate orientation shown in layout drawings),

secure with 3/4 x 4 hex bolts

, secure with 3/4 lock

washers and 3/4 nuts.

46. Attach treader gang assembly

to treader mount

with 3/4 x 4 hex bolts

, 3/4 flat washers

(one

on top and one on bottom of plates, secure with 3/4

lock washers and 3/4 nuts.

47. When all rolling harrow assemblies are bolted up to

drag frame, position as shown in “Layout Section” of

this manual and tighten all bolts to specs, See

“Torque Values Chart” on page 15.

1

2

3

4

1

5

6

1

7

10

11

8

9

11

1

8

9

10

10

18

11

19

12

11

11

6

12

13

14

15

16

14

15

17

Figure 11

Treader Gang

43032

8

6

5

2

9

1

7

4

3

11

15

14

13

12

10

17

16

15

18

19