Depth stop tube assembly, Wheel/tire & frog assembly – Great Plains 9756PP Predelivery Manual User Manual

Page 13

Great Plains Manufacturing, Inc.

Assembly

9

02/17/2014

580-043Q

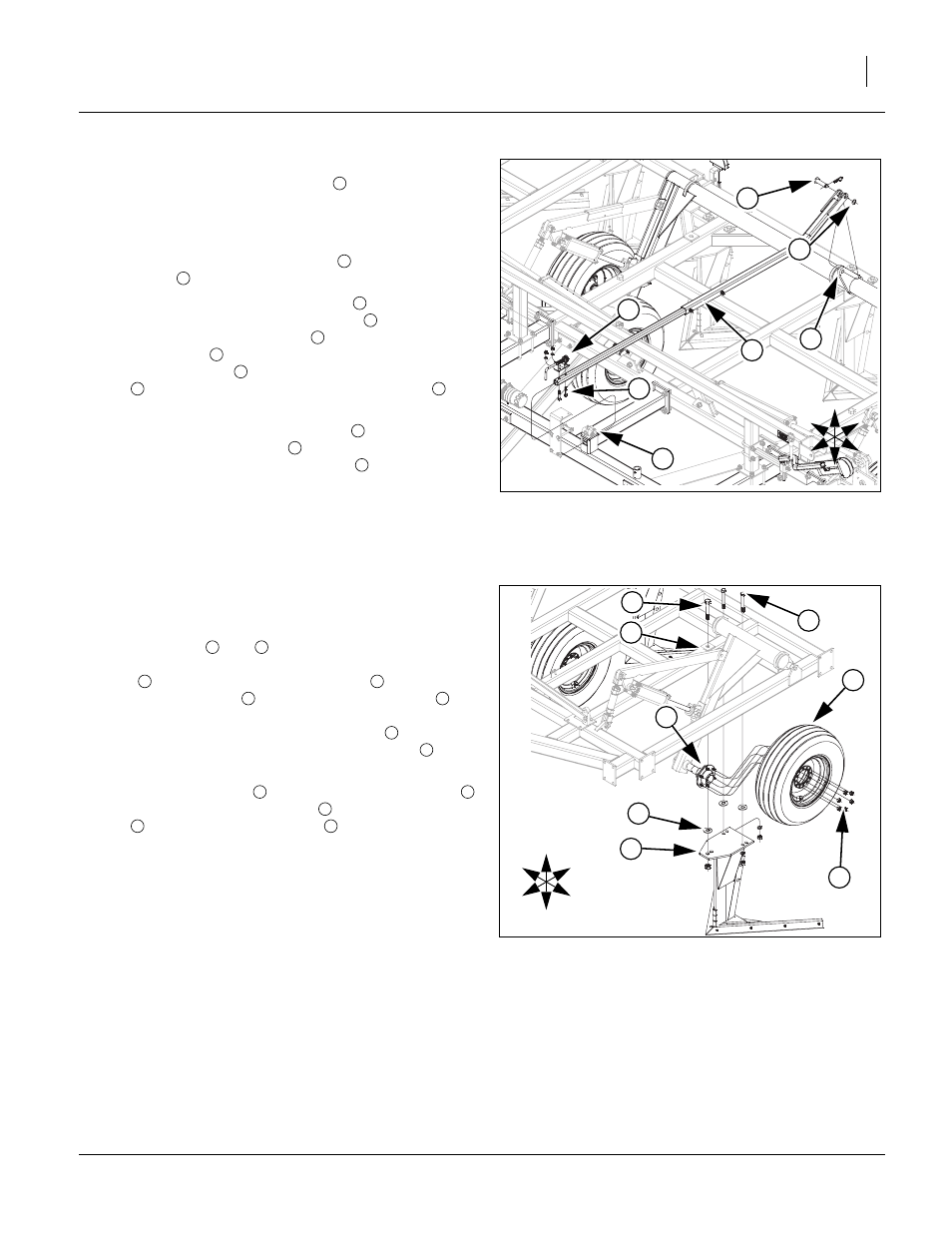

Depth Stop Tube Assembly

Note: The depth stop tube assembly

will be banded to the

rear tube of center frame. Carefully remove banding

from depth stop tube assembly.

Refer to Figure 6

26. Remove the 1/2 x 2 1/2 hex bolts

from the depth stop

assembly

.

27. Slide the depth stop tube assembly

, from rear,

through the square hole of slide tube

in orientation

shown. Remove 1 x 3 3/8 pin

from rear of depth stop

tube assembly

and re-install pin through aligned holes

of torque tube ear

and ear of depth stop tube assem-

bly

. Install the 1.5 x 1.00 x 0.075 flat washer

and 3/

16 x 2 cotter pin. Bend cotter pin over to secure.

28. Re-attach the depth stop assembly

to the front of

depth stop tube assembly

in orientation shown.

Secure with the 1/2 x 2 1/2 hex bolts

, 1/2 lock washers

and 1/2 nuts.

29. Bolt may be tightened to specs, See “Torque Values

Wheel/Tire & Frog Assembly

Refer to Figure 7

Note: Models 9533, 9744 & 9748 the outside wing frogs and

wheel/tire will not be installed.

30. Remove bolts

and

from outside wing frame.Unfold

outside wing and lower machine down to just above the

frog

. Align holes in top plate of frog

and holes in

outside wing frame

. Install the 1 flat washers

between frog plate and bottom of wing frame (all three

holes). Re-install the front 1 x 8 hex bolt

, secure with

the 1 lock nut. Re-install the 3/4 x 6 hex bolts

, secure

with the 3/4 lock washers and 3/4 nuts.

31. Remove the lug nuts

from spindle/hub assembly

.

Install the wheel/tire assembly

to spindle/hub assem-

bly

. Secure with the lug nuts

.

32. Tighten lock nuts snug but do not torque. The rest of

bolts may be tightened to specs, See “Torque Values

Chart” on page 15.

Figure 6

Depth Stop Tube

43021

1

U

D

F

B

L

R

2

6

5

4

3

7

3

1

2

3

4

5

3

6

3

7

2

3

1

Figure 7

Wheel/Tire & Frog

43019

U

D

F

B

L

R

2

8

5

1

6

4

7

3

3

4

1

1

2

5

3

4

8

7

6

7

8