Prestart checklist, Field operation – Great Plains PH-20 Operator Manual User Manual

Page 15

13

Section 2 Operating Instructions

12/29/2011

PH-15, PH-20, PFH-15 and PFH-20 Precision Fertilizer Hitch 148-365M

Great Plains Mfg., Inc.

Section 2

Operating Instructions

This section covers general operating procedures. Experi-

ence, machine familiarity and the following information will

lead to efficient operation and good working habits. Al-

ways operate farm machinery with safety in mind.

Prestart Checklist

1.

Carefully read “Important Safety Information,” be-

ginning on page 1.

2.

Lubricate implement as indicated under Lubrication,

“Maintenance and Lubrication,” page 33.

3.

Check all tires for proper inflation as indicated on Tire

Inflation Chart, “Appendix,” page 40.

4.

Check all bolts, pins and fasteners. Torque as speci-

fied on Torque Values Chart, “Appendix,” page 40.

5.

Check implement for worn or damaged parts. Repair

or replace before going to the field.

6.

Check hydraulic hoses, fittings and cylinders for leaks.

Repair or replace before going to the field.

Field Operation

You may be severely injured or killed by being crushed between

the tractor and hitch. Do not stand or place any part of your

body between hitch and moving tractor. Stop tractor engine and

set park brake before installing the hitch pin.

Escaping fluid under pressure can have sufficient force to pene-

trate the skin. Check all hydraulic lines and hoses before apply-

ing pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, to

check for suspected leaks. If injured, seek medical assistance

from a doctor that is familiar with this kind of injury. Foreign

fluids in the tissue must be surgically removed within a few

hours or gangrene will result.

1.

Hook hitch to a suitable tractor and drill. Refer to

Hooking Hitch to Tractor and Hooking Hitch to Drill,

“Preparation and Setup,” page 8.

2.

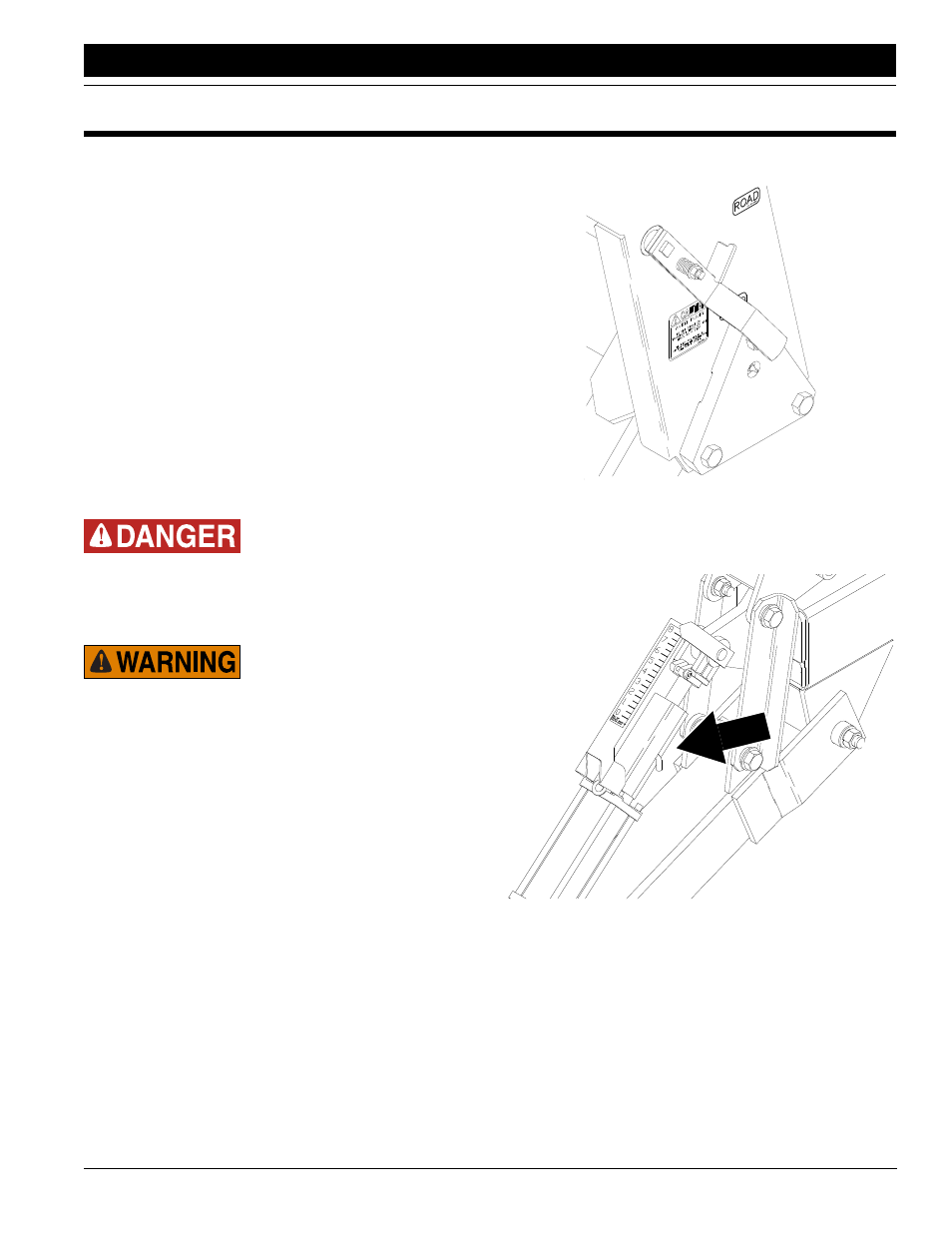

Move transport-lock handle to field position. See Fig-

ure 2-1.

Figure 2-1

Transport-Lock Handle, Field Position

3.

Remove cylinder lock channel from tongue cylinder.

See Figure 2-2.

Figure 2-2

Cylinder Lock Channel

12330

12483