Disc blade adjustments – Great Plains 3S-5000HDF Operator Manual User Manual

Page 55

Great Plains Manufacturing, Inc.

Adjustments

51

2012-08-14

195-325M

3.

After adjusting, lock flange nut in place with jam nut.

The length

of the spring is factory-set to:

13

5

⁄

16

in. (33.8 cm).

The reference points for this length are the

center of the upper/front clevis pin

and

the base of the lower/rear spring stop cup

.

The factory preset length is recommended for

conventional till and min-till conditions. Shorten it for

rows in tire tracks or more difficult min-till conditions. The

minimum recommended length is:

12

5

⁄

16

in. (31.3 cm).

Disc Blade Adjustments

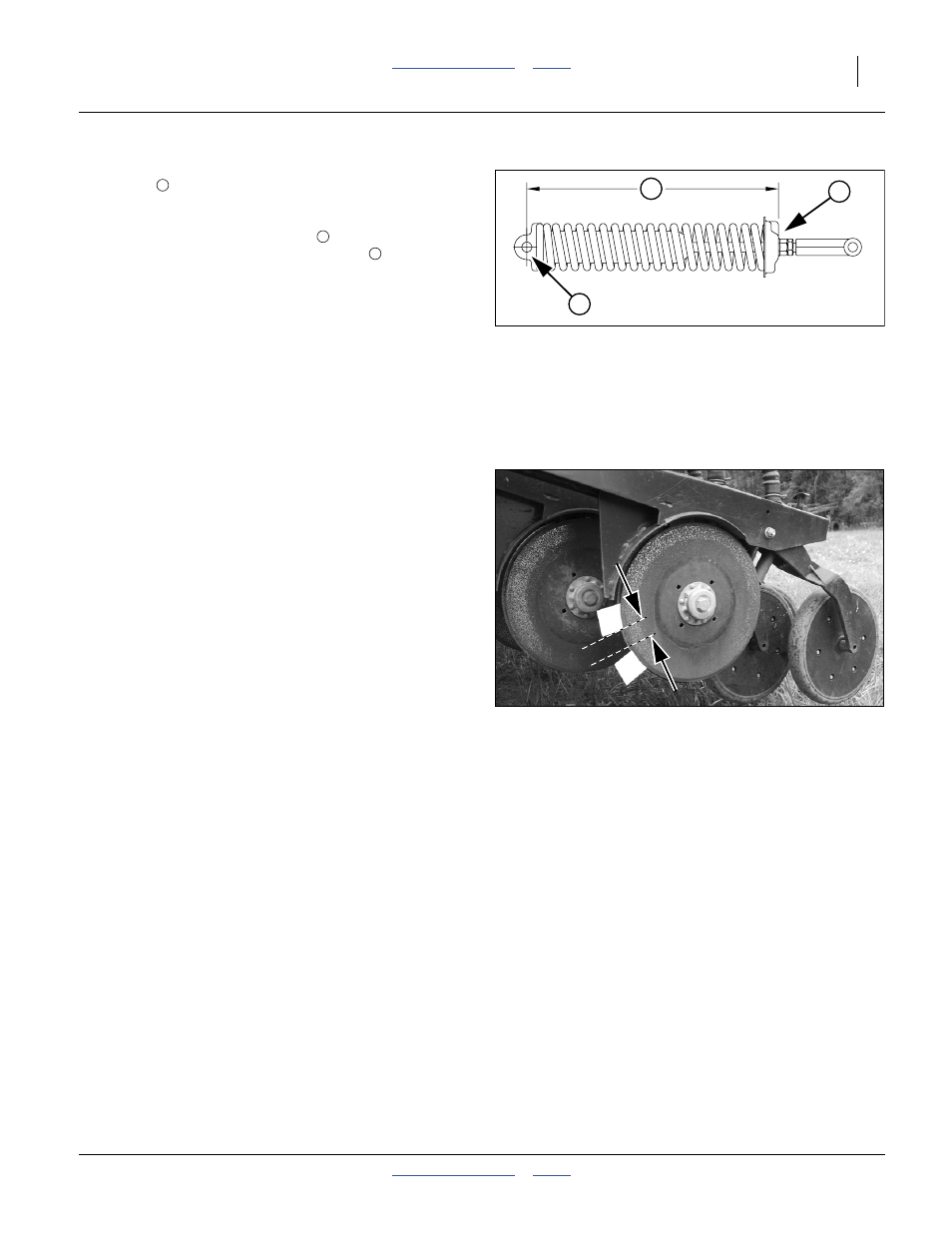

Opener disc angle and stagger is not adjustable, but

disc-to-disc spacing is, and may need attention as discs

experience normal wear. Spacers must be reset when

blades are replaced.

Refer to Figure 49

The ideal spacing causes the blades to be in contact for

about one inch. If you insert two pieces of paper between

the blades, the gap between them should be 0 to 1.75 in.

(0 to 4.4 cm).

If the contact region is significantly larger or smaller (or

there is no contact at all), it needs to be adjusted by

moving one or more spacer washers. If the contact

region varies with blade rotation, one or both blades is

likely bent and in need of replacement.

Figure 48

00 Series Spring Length

26454

3

2

4

2

3

4

Figure 49

Checking Disc Contact

26451