C - b = 1 to 11§4 inch, Wing box alignment, Tool bar height – Great Plains 3S-5000HDF Operator Manual User Manual

Page 21: Wing box alignment tool bar height

Great Plains Manufacturing, Inc.

Preparation and Setup

17

2012-08-14

195-325M

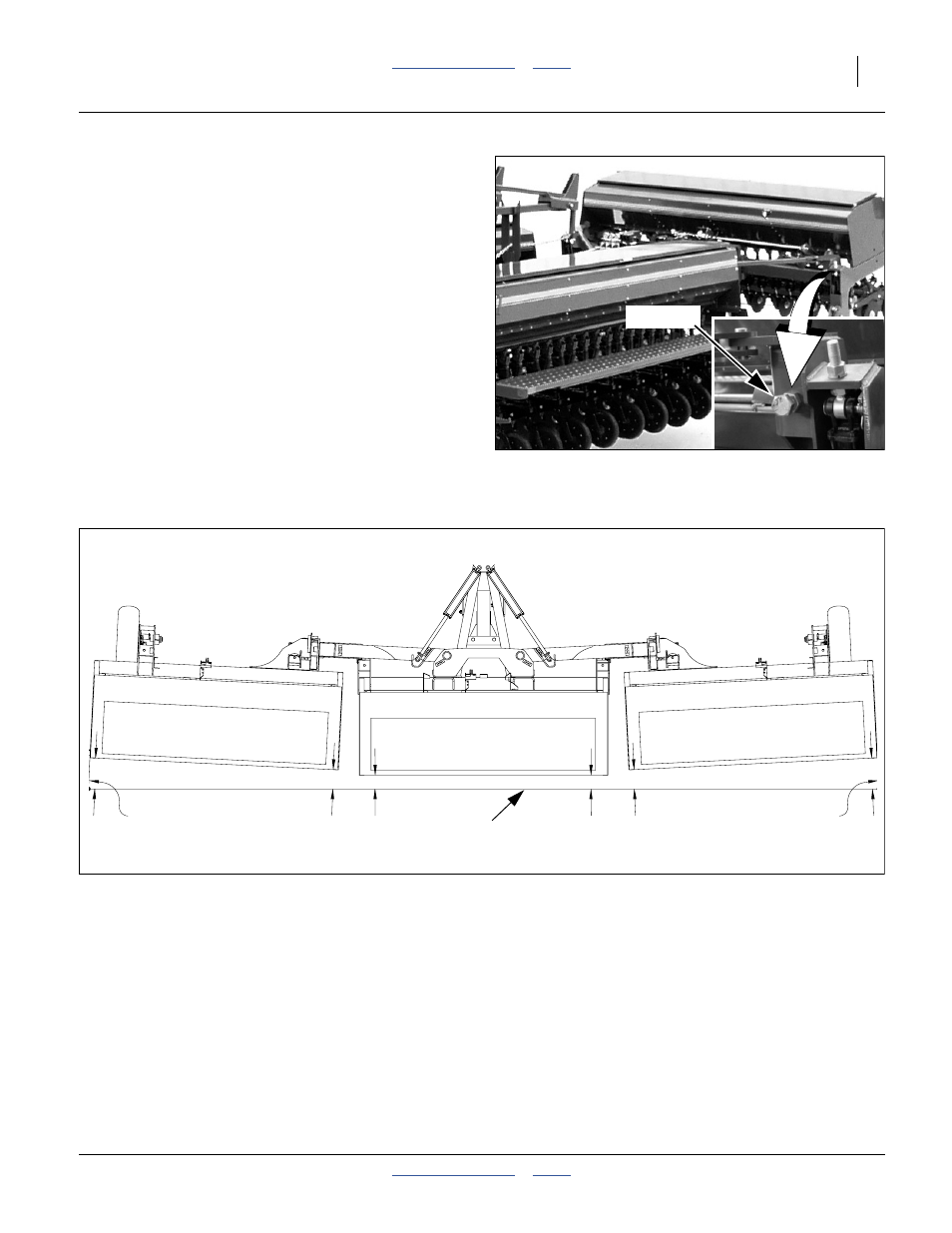

Wing Box Alignment

1.

Place a block ahead of the wing gauge wheels.

Refer to Figure 5

2.

Pull forward against blocks to rock wing frames back.

Pull forward until stop bolts are firmly against tool

bars.

Refer to Figure 6

3.

Check for proper alignment by running a string line

across back of drill toward outer ends of wings. For

proper alignment, outside ends of boxes should be

about 1 inch to 1

1

⁄

4

inch (25 to 32 mm) ahead of

inside ends.

4.

To adjust box alignment, shorten or lengthen stop

bolts to change the contact point with the tool bars.

Adjust stop bolts in or out until outside ends of boxes

are 1 inch to 1

1

⁄

4

inch (25 to 32 mm) ahead of inside

ends.

Tool Bar Height

Tool bar height is factory set and normally will not require

adjustment. If the tool bar is visibly not level see “Tool

Bar Height Adjustment” on page 44.

Figure 5

Stop Bolt Location

18988

Stop Bolt

Figure 6

Wing Box Alignment Measurement

15654

String Line

String Line

Support

String Line

Support

A

A

B

C

B

C - B = 1 to 1

1

⁄

4

inch