Maintenance intervals, Maintenance procedures, Visual inspection – Wheatheart Transfer Auger User Manual

Page 34: Maintenance intervals 6.2. maintenance procedures

6. M

AINTENANCE

W

HEATHEART

M

ANUFACTURING

- T

RANSFER

A

UGER

6.1. M

AINTENANCE

I

NTERVALS

8”, 10”, & 13”

34

IM2 R2

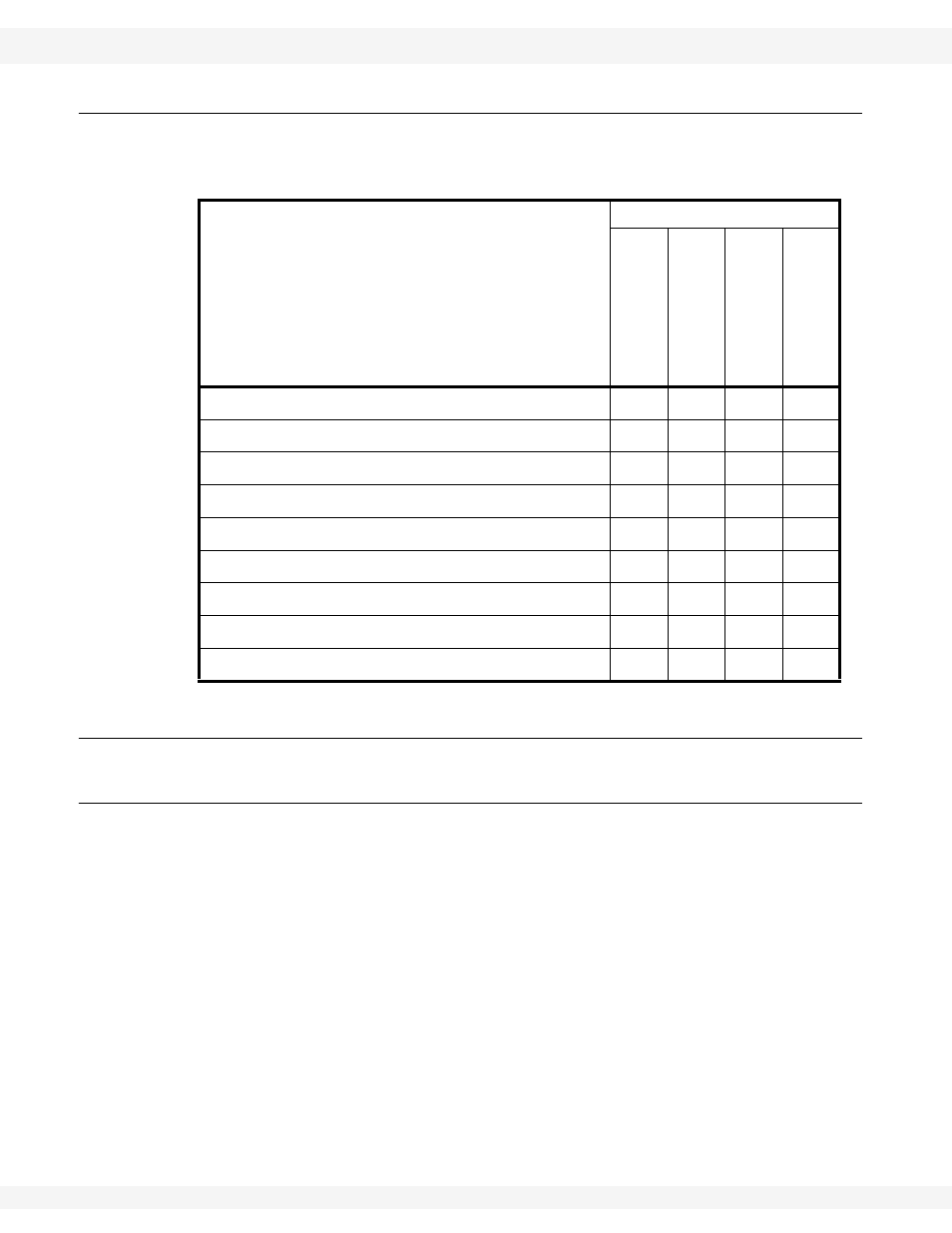

6.1. MAINTENANCE INTERVALS

Details of service are listed in Section 6.2.

6.2. MAINTENANCE PROCEDURES

6.2.1. V

ISUAL

I

NSPECTION

Before beginning the visual inspection, chock auger wheels and ensure that all

operators are aware of safety precautions.

When inspecting:

• Ensure all guards are in place, and in good working order.

• Examine the auger for damage or unusual wear.

• Inspect the machine for evidence of oil leaks.

• Examine hydraulic hoses and fittings for leaks and cracks.

• Be sure all safety decals are in place and are legible.

• ELECTRIC DRIVE: Check that drive belts are not frayed or damaged.

Ensure they are properly adjusted and aligned.

• Check that the discharge spout and intake area are free of obstructions.

• Ensure that intake housing fasteners are properly secured.

• Examine all flighting for damage or unusual wear.

Table 6.1

Time Period

Daily

(8000

BU)

Periodica

lly

(40

,000 BU)

An

nually

(Before S

to

rag

e)

An

nually

(Af

ter S

torag

e)

Visually inspect the unit.

Check engine oil level.

Check air filter.

Service belts.

Grease machine.

Check gearbox oil level (gas models).

Clean machine.

Service engine (gas & electric models).

Change gearbox oil.