General storage procedures, Caution – Wheatheart WHR 80/100 x 31-71ft Augers PTO-SD User Manual

Page 50

6. M

AINTENANCE

& S

TORAGE

WHEATHEART - GHR & WHR GRAIN AUGERS

6.2. G

ENERAL

S

TORAGE

P

ROCEDURES

PTO-SD D

RIVE

M

ODEL

50

30641 R1

6.2. GENERAL STORAGE PROCEDURES

T

O

PROTECT

AUGER

IN

STORAGE

DURING

THE

OFF

-

SEASON

:

1. Lower the auger to full down position with slight tension on the cable.

2. Lubricate all grease fittings according to the maintenance procedure.

3. Inspect auger for damage and note any repairs required. Order replacement

parts from your dealer.

4. Check tire pressure and inflate if necessary. See tire sidewall for recommen-

dations.

5. Clean and re-lubricate spline on PTO driveline. Cover PTO driveline with

plastic bag to protect it from the weather and place in the transport saddle.

6. Tow auger to storage area. Park and chock wheels.

T

O

PREPARE

AUGER

FOR

USE

AFTER

STORAGE

:

1. Check tire pressure and inflate if necessary. See tire sidewall for recommen-

dations.

2. Tow auger to work site.

3. Remove cover from spline of PTO driveline and re-lubricate.

4. Check oil level in gearbox and refill if necessary (half full only).

5. Replace any damaged parts and decals.

6. Conduct general maintenance procedures before using auger.

7. Before raising auger after storage, make certain cable is in good condition,

replacing it if frayed or damaged. Also make sure cable is properly seated in

roller track and that cable clamps are secure.

8. On augers equipped with lubricated upper drive, check level of lubrication

annually and add as needed. Refill to plug level.

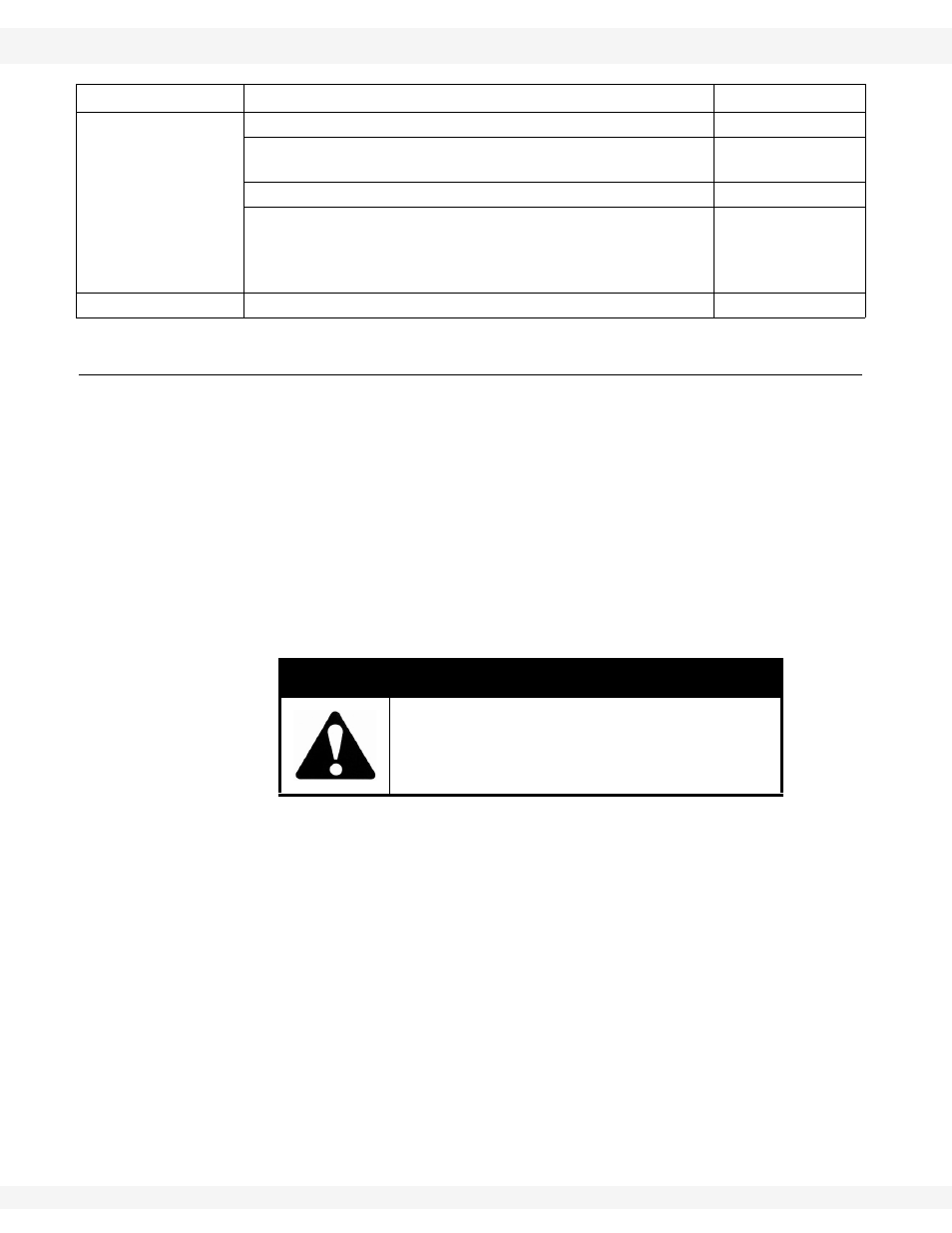

Winch

Note: Service

winch with auger in

fully lowered posi-

tion and cable

slack.

Keep a film of grease on gears.

Regularly

Oil the ratchet pawl pivot, bushings, and pinion threads.

Do not get oil or grease on brake discs.

Occasionally

Replace brake discs if less than 1/16” (1.6 mm) thick.

As required

Check for proper ratchet pawl operation.

When cranking in (clockwise) = loud clicking

When cranking out (counterclockwise) = no clicking and

ratchet pawl fully engaged into gear teeth

Regularly

Truss Cables

Adjust to keep auger tube reasonably straight.

As necessary

Area

Maintenance Procedure

Frequency

CAUTION

Support discharge end of auger before

removing or replacing any parts on the

undercarriage.