Installation of bushings – Viking Pump TSM445: LVP Vane Pumps User Manual

Page 9

SECTION TSM 445

ISSUE

C

PAGE 9 OF 11

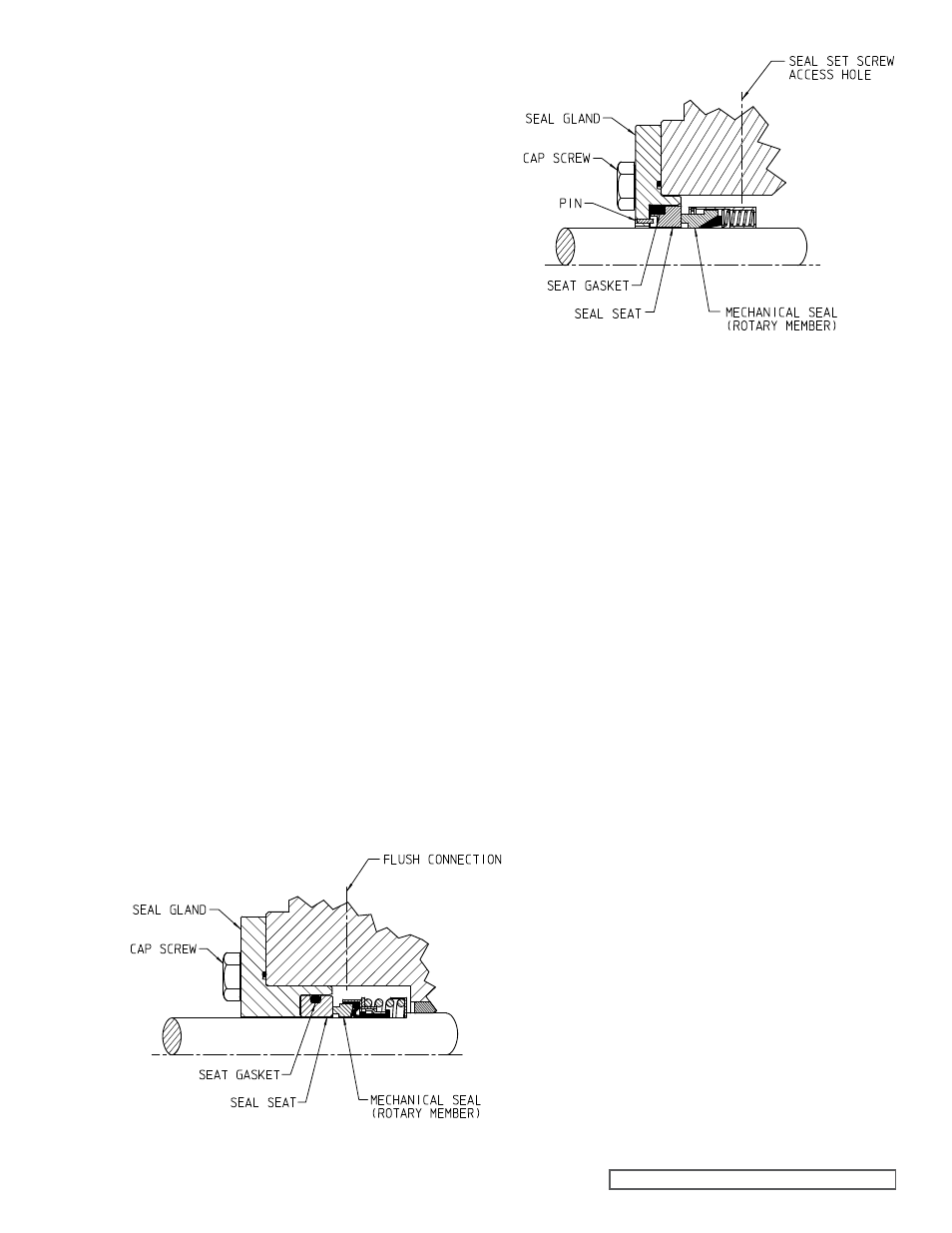

fIgURE 13

Elastomeric Bellows Seal

fIgURE 14

PTfE Wedge Seal

For complete pump assembly instructions, see

“Assembly,”

page 7.

1. Clean

the rotor shaft and seal housing bore. Make sure

they are free of dirt, grit and scratches. Gently radius the

leading edge of the shaft diameter over which the seal is

to be placed.

NOTE: Never touch the mechanical seal faces with

anything except clean hands or a clean cloth. Minute

particles can scratch the seal faces and cause leakage.

2. Coat

the shaft and the inside of the rotary member of

the seal with a generous quantity of light oil. Grease is

not recommended.

3. Start

the rotary member on the shaft (including the seat

collar and screws on the bellows seal) and ease over the

shaft.

NOTE: Some PTFE wedge seals are equipped with

holding clips, which compress the seal springs. Remove

the holding clips to release the springs after the seal is

installed on the shaft.

4. For PTFE wedge seal, move the rotary member so

the setscrews are directly below the seal access holes

on the side of the bracket (See

figure 14). Tighten all

setscrews securely to the shaft.

5. FOR “O-RING” GASKET TYPE MECHANICAL SEAL

SEAT (BELLOWS SEAL): Lubricate the outer diameter

of the O-ring seal gasket with oil. Flush the sealing faces

of both rotary member and seal seat with oil and press

the seal seat in to the bore until the back, unlapped face,

is flush with the bore. Install the seal holder, seal plate,

capscrews, and nuts and tighten securely.

FOR “CLAMPED-IN” TYPE MECHANICAL SEAL SEAT

(WEDGE SEAT): Flush the sealing faces of both the

rotary member and seal seat with oil and install the seal

seat and seal gasket over the end of the shaft against

the machined bracket face. Install the other seal gasket,

seal holder, seal plate, capscrews and nuts and fasten

securely.

NOTE: For component seals, LVP pumps come standard

with an internal suction lubrication line.

To complete assembly, refer to

“Assembly,” page 7.

Elastomeric Bellows and PTfE Wedge Type :

INSTALLATION Of BUSHINgS

When installing the silicon carbide or carbon graphite

bushings, extreme care must be taken to prevent breaking.

Carbon graphite is a brittle material and easily cracked. If

cracked, the bushing will quickly disintegrate. Using a lubricant

and adding a chamfer on the bushing and the mating part will

help in installation. The additional precautions listed below

must be followed for proper installation.

1. A press must be used for installation.

2. Be certain the bushing is started straight.

3. Do not stop pressing operation until the bushing is in

the proper position. Starting and stopping will result in a

cracked bushing.

4. Check

the bushing for cracks after installation.

LVP bushings with interference fits must be installed by a

shrink fit.

1. Heat

the casing or head to 750ºF.

2. Install

the cool bushing with a press.

3. If facilities are not available to reach 750ºF. temperature,

it is possible to install with 450ºF. temperature; however

the lower the temperature the greater the possibility of

cracking the bushing.

Consult factory with specific questions on high temperature

applications.

Refer to Engineering Service Bulletin ESB-3.