Disassembly – Viking Pump TSM445: LVP Vane Pumps User Manual

Page 5

SECTION TSM 445

ISSUE

C

PAGE 5 OF 11

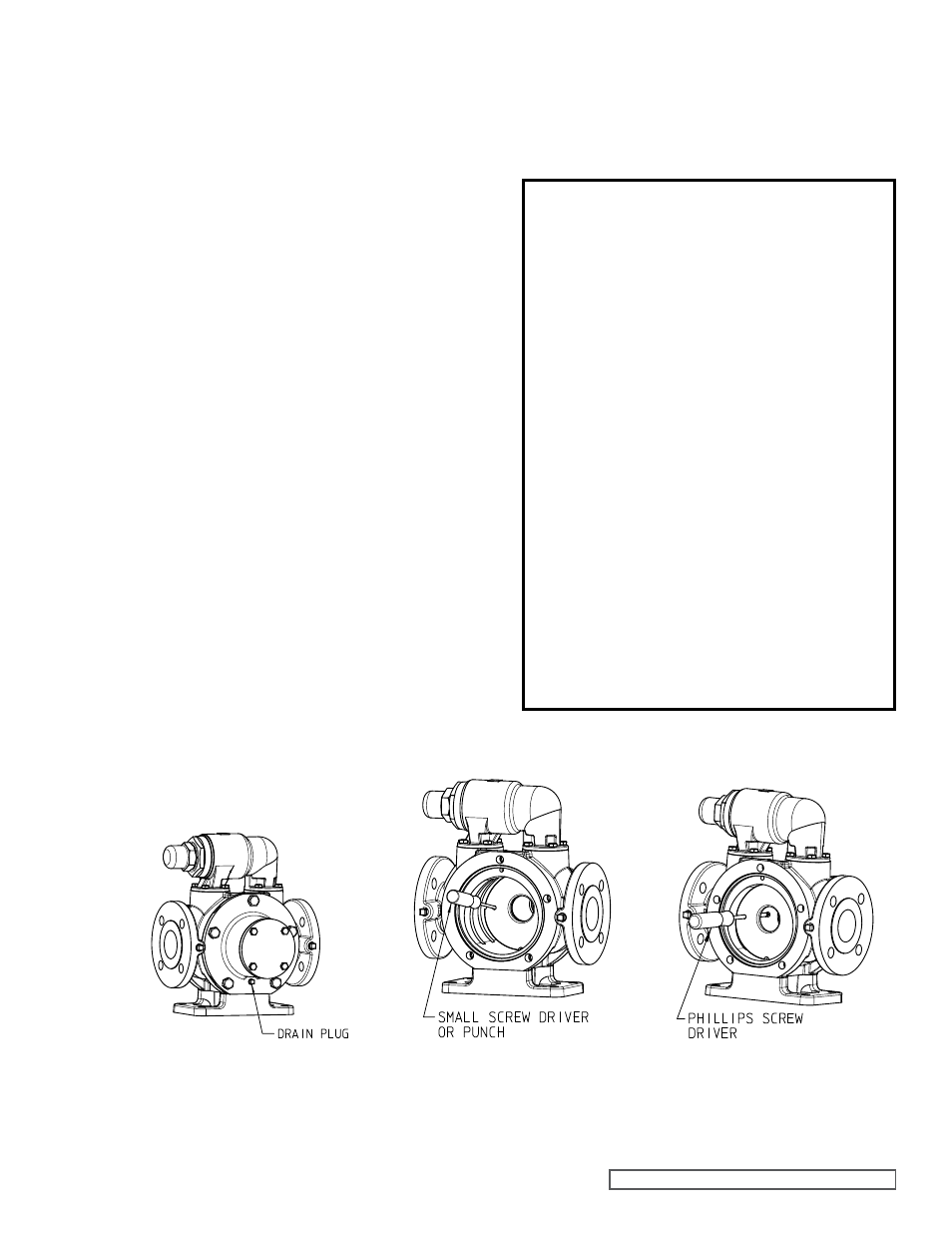

1. Mark the head and casing before disassembly to ensure

proper reassembly.

2. Relieve pressure and drain fluid by removing the drain

plug as shown in

figure 4.

3. Remove the head from the pump. If the pump is

furnished with a pressure relief valve, it need not be

removed from casing or disassembled at this point. Refer

to

“Pressure Relief Valve Instruction,” page 10.

4. Remove

the first carbon disc using caution not to break.

See

figure 5.

5. Remove the top vane from the rotor. Ensure the

pushrod is not obstructing the vane being removed.

Rotate the shaft and remove the other vanes in the same

manner.

6. Remove the seal gland capscrews, slide packing gland

out of the seal box, and remove the seal.

7. Loosen the mechanical seal setscrews for applicable

seals.

8. Ensure the pushrods are not lodged in ports prior to

removing the rotor.

NOTE: When disassembling a pump with a cartridge seal,

reference cartridge seal replacement beginning on page 8.

9. Carefully remove the rotor and shaft to avoid damaging

the bracket bushing. One or more pushrods may fall out

of the rotor upon removal from the casing. Take care

to not jam the pushrods between the casing and rotor

during the rotor removal.

10. Carefully remove the second carbon disc from the

casing. If the casing disc is jammed, a small screwdriver

or punch may be used as shown in

figure 5. Use the

screwdriver to help guide the disc out of the casing cam

bore as shown in

figure 6.

11. Press the bushings out of the casing and head if

replacement is needed. For the head bushing, remove

the head cover plate before pressing out the bushing.

DISASSEMBLY

DANgER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor,

turbine, engine, etc.) has been “locked

out” or made non-operational so that

it cannot be started while work is

being done on pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

failure to follow above listed

precautionary measures may result in

serious injury or death.

12. Clean all parts thoroughly and examine for wear and

damage. Check the bushings, carbon discs, vanes,

pushrods and replace if necessary. Check all other

parts for nicks, burrs, excessive wear and replace if

necessary.

fIgURE 4

Location of drain plug.

fIgURE 5

Removal of Disc.

fIgURE 6

Use screwdriver to guide disc out.