Seal removal seal installation, Mechanical seal replacement – Viking Pump TSM445: LVP Vane Pumps User Manual

Page 8

SECTION TSM 445

ISSUE

C

PAGE 8 OF 11

DANgER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor,

turbine, engine, etc.) has been “locked

out” or made non-operational so that

it cannot be started while work is

being done on pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

failure to follow above listed

precautionary measures may result in

serious injury or death.

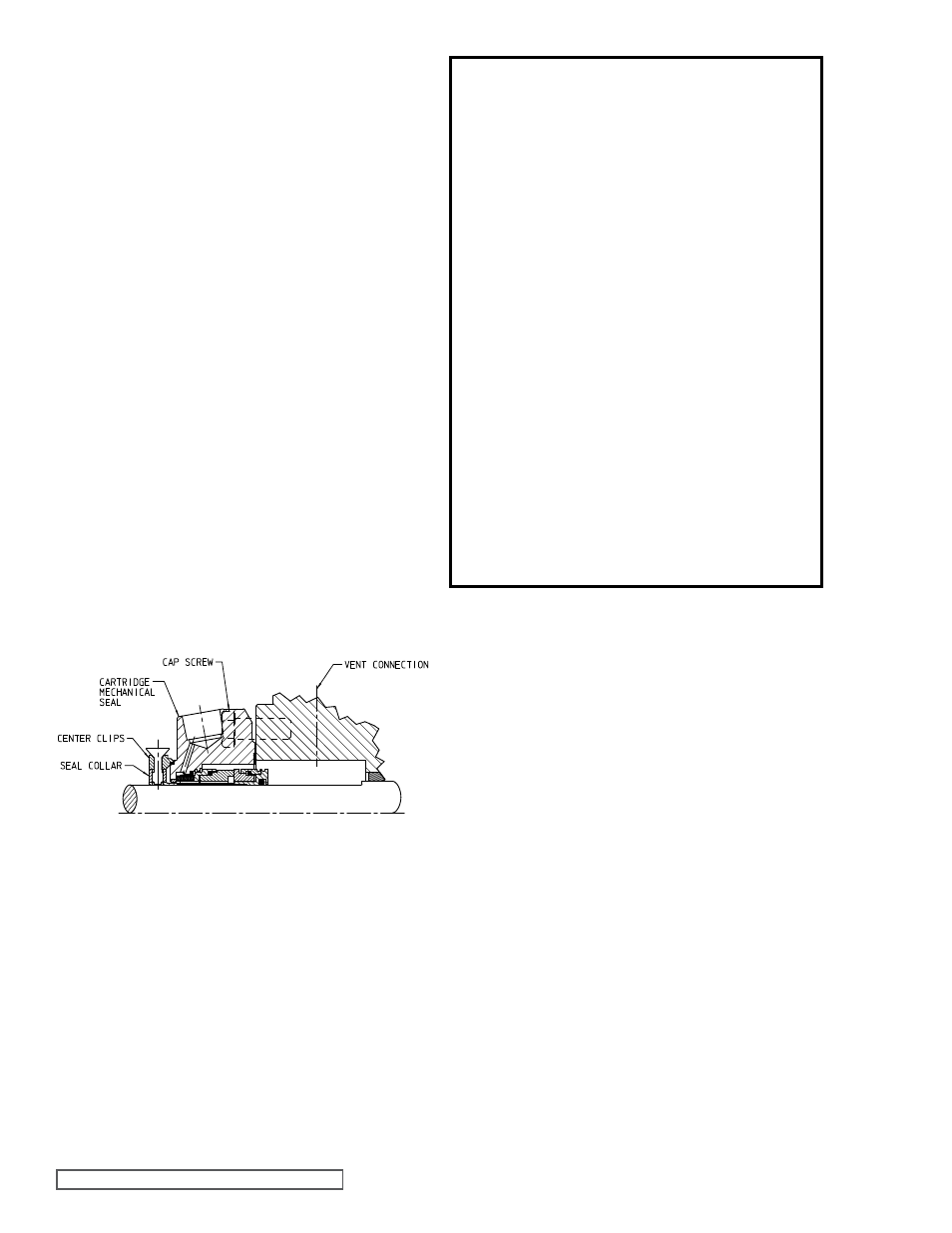

fIgURE 12

Cartridge Mechanical Seal

SEAL REMOVAL

SEAL INSTALLATION

Cartridge Type :

This manual provides instructions for the three standard

types of mechanical seals supplied on the following LVP vane

pump models:

LVP40017U, LVP40027U, LVP41057U, LVP41087U,

LVP41197U, LVP41237U, LVP41017U, LVP41027U,

LVP40017M, LVP40027M, LVP41057M, LVP41087M,

LVP41197M, LVP41237M, LVP41017M, LVP41027M

1. Cartridge

(figure 12)

2. Elastomeric Bellows Type 52, 8-1 (figure 13)

3. PTFE Wedge Type 9 (figure 14)

Identification of the seal type is an important step towards

proper maintenance. For mechanical seal types not shown,

see the Seal Instruction Drawing (SID) furnished with the

pump or contact a Viking representative.

Cartridge mechanical seals are designed so that they may be

replaced with minimal pump and piping disassembly.

1. Remove any flush or barrier fluid tubes connected to the

seal gland.

2. Loosen the setscrews on the seal collar to free the

cartridge seal from the shaft.

3. Remove the gland capscrews and slide the cartridge

seal off the end of the shaft.

If the pump is to be disassembled further, refer to

“Disassembly,” page 5.

Elastomeric bellows and PTFE wedge seals generally

require pump disassembly to be replaced (See

“Disassembly,” page 5).

1. Loosen the nuts and remove the seal gland plate, seal

plate holder, seal seat and seal gasket.

2. Loosen the setscrew in the set collar (bellows) or

mechanical seal rotary member (wedge).

NOTE: Piping

and/or plugs will need to be removed to access the

setscrews.

3. To complete the removal of the mechanical seal refer to

Step 6 of

“Disassembly,” page 5.

NOTE: Burrs left on the shaft can damage the O-ring on the

seal sleeve during installation. Inspect the shaft for burrs and

remove with a fine grade of emery cloth.

1. Clean

the shaft and the face of the seal chamber.

2. Coat the shaft and O-ring in the inside diameter of the

cartridge seal sleeve with a generous amount of light oil.

Refer to

figure 12.

3. Slide

the cartridge seal on the shaft until it contacts the

seal chamber face.

4. Insert

the gland capscrews and secure the gland to the

bracket face.

NOTE: Turn the shaft several turns while

the gland is loose to center seal; then tighten gland tight

enough to compress the gasket. Tighten only enough to

contain leakage and not to distort the gland.

5. Lock the cartridge seal drive collar to the shaft and

remove or turn the centering clips out of the way so as to

clear the drive collar.

6. Turn

the shaft by hand or jog the motor to check the

drive collar for runout.

7. Connect

the flush line or vent the stuffing box for seals

without the flush line until liquid is present on start up.

NOTE: For maximum seal life, the flush line should be

used.

MECHANICAL SEAL REPLACEMENT

Cartridge Type :

Elastomeric Bellows and PTfE Wedge Type :